Vertical mill with double oscillating device

A vertical grinding and double-swing technology, applied in the field of grinding mills, can solve the problems that the design output of the grinding mill cannot be achieved, the user cannot continue to produce, and the output of the grinding mill is reduced, etc., and can prevent the powder from entering the bearing chamber. , The effect of rapid and convenient replacement, reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

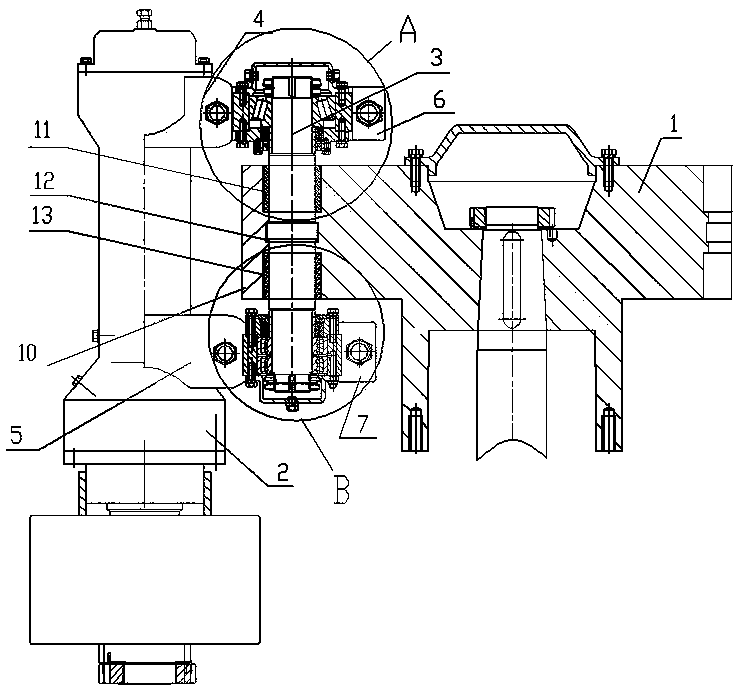

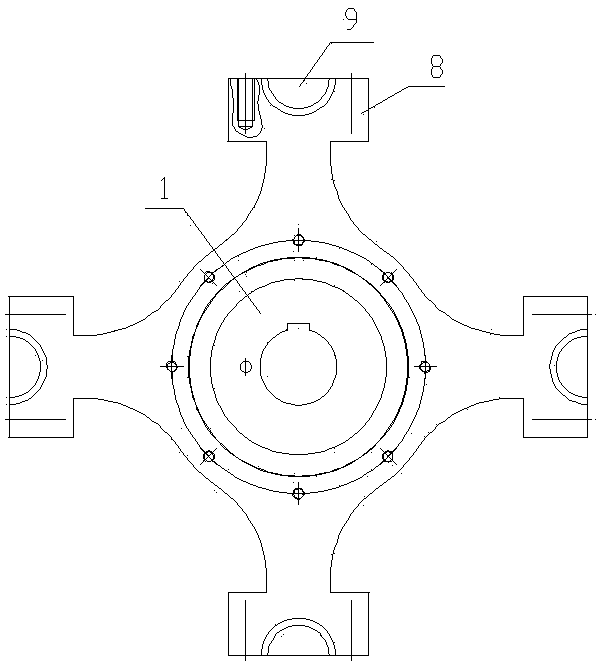

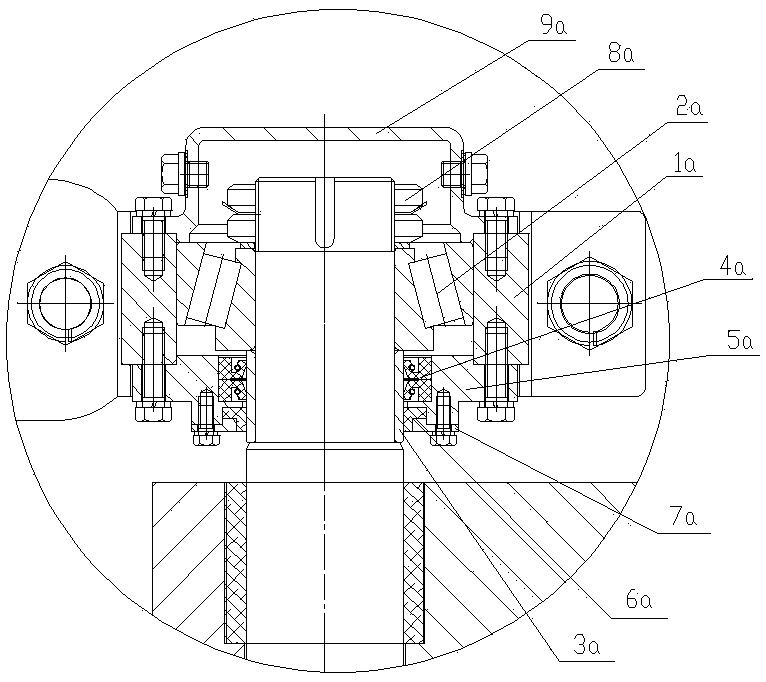

[0016] Such as figure 1 , 2 As shown, the vertical mill with double swinging devices according to the present invention includes a plum blossom frame 1 placed in the body and a grinding roller assembly 2 balancedly arranged on the plum blossom frame and driven by a suspension mechanism. The suspension mechanism includes a vertical shaft 3, a first rotating assembly is provided at the upper end of the vertical shaft 3, a second rotating assembly is provided at the lower end of the vertical shaft 3, and the grinding roller assembly 2 corresponding to the position of the first rotating assembly and the second rotating assembly is provided. There are upper connecting ear 4 and lower connecting ear 5. The first rotating assembly is fixedly connected to the upper connecting ear 4 through the upper finale cover 6 covering it, and the second rotating assembly is connected to the lower connecting ear through the lower finalizing cover 7 covering it. The connecting ears 5 are fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com