Patents

Literature

41results about How to "Achieving sustainable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizer special for eucalyptus and fertilizer application method

InactiveCN102070366AHealthy growthIncrease profitFertilising methodsFertilizer mixturesSoil scienceEdaphic

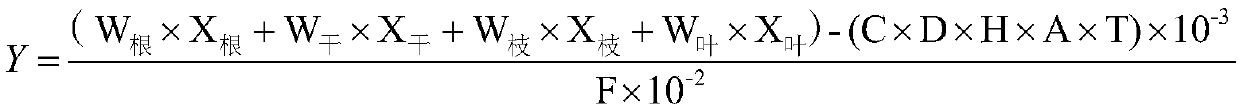

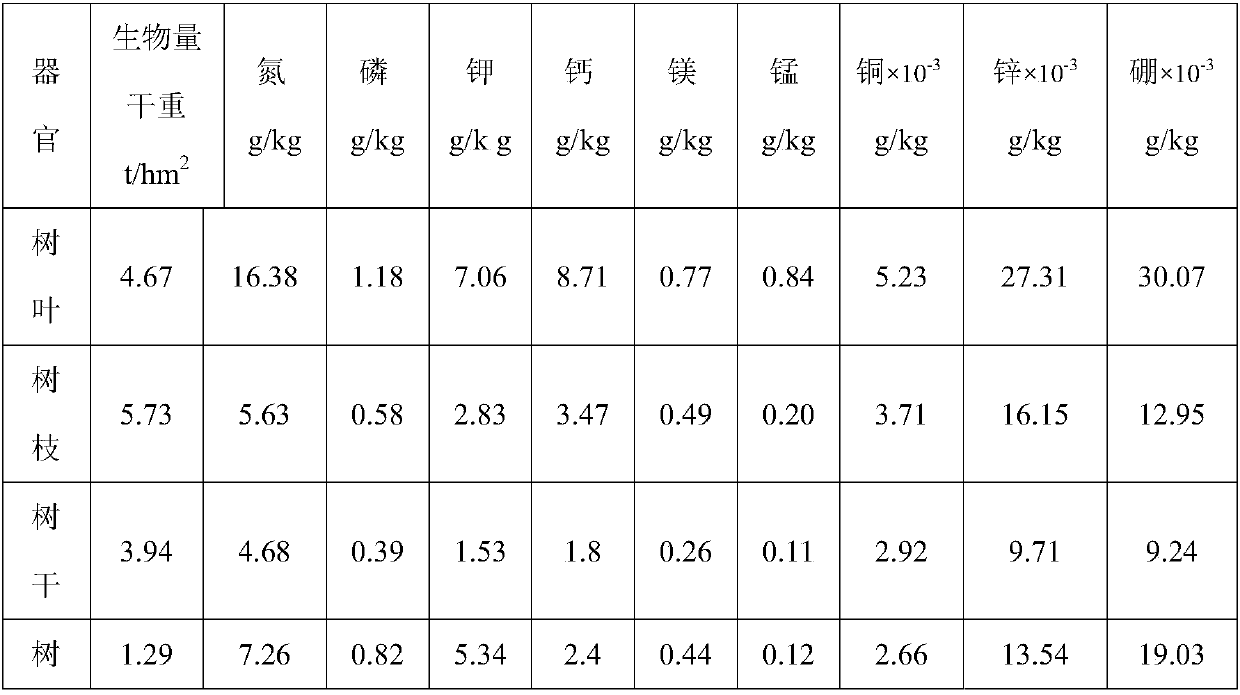

The invention provides a fertilizer special for eucalyptus and a fertilizer application method. The fertilizer special for the eucalyptus is characterized in that: a eucalyptus base fertilizer consists of the following fertilizers in percentage by mass: 12 to 30 percent of nitrogen fertilizer, 55 to 70 percent of phosphate fertilizer, 8 to 20 percent of potassium fertilizer, 0.5 to 2 percent of boron fertilizer and 0.2 to 0.5 percent of zinc fertilizer; and a eucalyptus additional fertilizer consists of the following fertilizers in percentage by mass: 20 to 35 percent of nitrogen fertilizer, 50 to 65 percent of phosphate fertilizer, 10 to 30 percent of potassium fertilizer, 0.5 to 2 percent of boron fertilizer and 0.2 to 0.5 percent of zinc fertilizer. The fertilizer special for the eucalyptus contains nitrogen, phosphorus, potassium, boron, zinc, calcium and magnesium which are essential to the growth of eucalyptuses, reduces the waste of fertilizers caused by volatilization, loss and soil absorption and fixation, increases the utilization rate of the fertilizers, improves the growth amount and physiological disease resistance of the forest, develops the fast-growing advantage of the eucalyptuses, realizes the cultivation of short-cycle industrial raw material forest of the eucalyptuses, greatly shortens the circulation period of industrial raw material forest of the eucalyptuses, can also remedy mineral substances and nutrient components which are taken away by hacking the eucalyptuses at the same time to ensure the nutrient balance of the soil, brings maximum economic benefits with minimum fertilizer investment, and realizes the sustainable production of eucalyptus planting areas.

Owner:YUNNAN YUNJING FORESTRY & PULP MILL

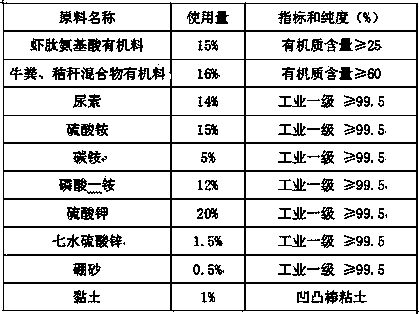

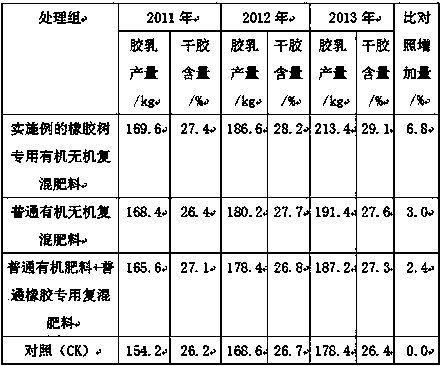

Fertilizer special for rubber trees and preparation method thereof

ActiveCN103819252AReasonable formulaImprove disease resistanceFertilizer mixturesFertilizerAmmonium sulfate

The invention discloses a fertilizer special for rubber trees, which is prepared from the following materials by weight percent: 15 percent of shrimp peptide amino acid organic material, 16 percent of cow dung and straw mixture organic material, 14 percent of urea, 15 percent of ammonium sulfate, 5 percent of ammonium bicarbonate, 12 percent of monoammonium phosphate, 20 percent of potassium sulphate, 1.5 percent of heptahydrate, 0.5 percent of borax and 1 percent of clay. The invention further discloses a preparation method for the fertilizer special for the rubber trees. According to the fertilizer special for the rubber trees, the fertilizer formula is reasonable; the requirement for comprehensive nutrition necessary for rubber tree growth is satisfied; the disease resistance of the rubber trees is improved; the occurrence of diseases is reduced; moreover, the utilization efficiency of the fertilizer is high; the longtime effect is achieved; the fertilizing frequency is reduced; the growing speed of the rubber trees is increased; the yield of dry rubber is improved; the continuous rubber production is realized.

Owner:中化农业生态科技(湖北)有限公司

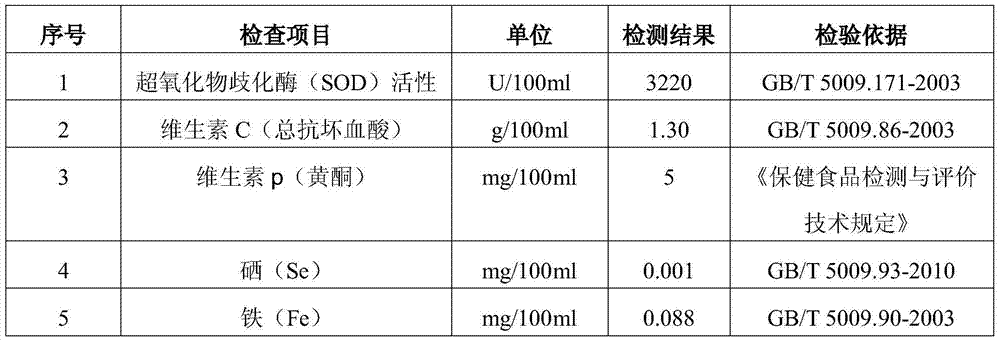

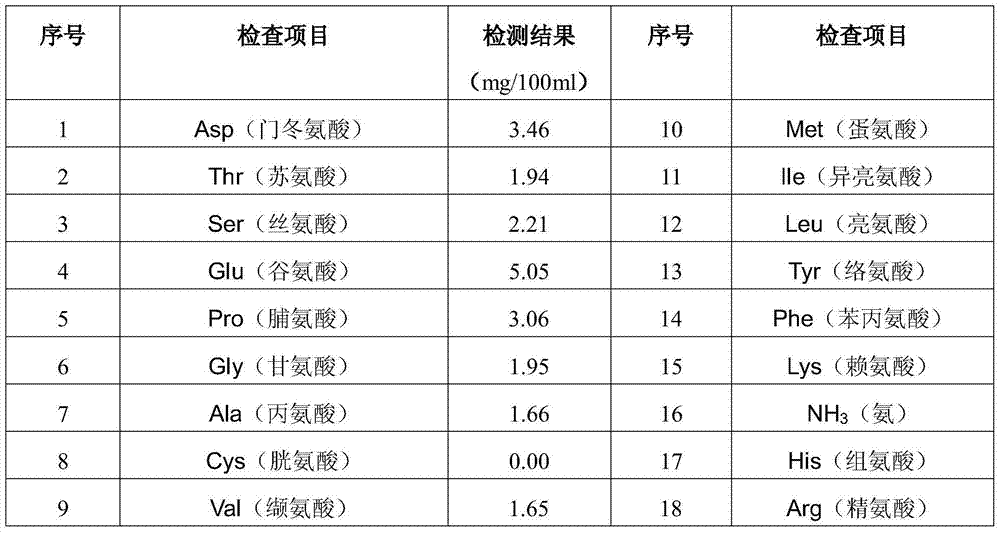

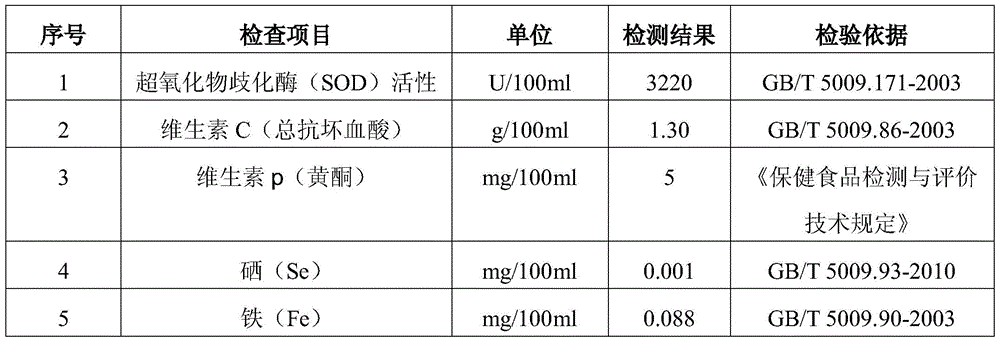

Fructose roxburgh rose juice beverage and production method thereof

InactiveCN103462133AAvoid restrictionsAchieving sustainable productionFood preparationBiotechnologyFructose

The invention discloses a fructose roxburgh rose juice beverage and a production method thereof. The beverage include the following raw materials in parts by weight: 1-2 parts by weight of dried roxburgh rose, 4-6 parts by weight of water and 4-12 parts by weight of fructose. The production method comprises the steps of picking out of the dried roxburgh rose, washing and sterilization of the dried roxburgh rose, primary extraction of the dried roxburgh rose, filtering of roxburgh rose juice mixed liquid, and sterilization and canning. The fructose roxburgh rose juice beverage is characterized in that the dried roxburgh rose is used as the raw material of production and out of limit of the fresh fruit period, and continuous production can be realized, and simultaneously, no preservative and other color additives are contained; the beverage is sweet and delicious, rich in nutrition, and also suitable for the diabetics to drink; furthermore, the production method is simple, low in production cost and suitable for large-scale industrial production.

Owner:GUANGXI RUIQIKANG BEVERAGE

Long-lasting special fertilizer for rubber tree and preparation method thereof

InactiveCN103408384AComplete NutritionImprove disease resistanceFertilizer mixturesSoil scienceNutrition

The invention discloses a long-lasting special fertilizer for a rubber tree and a preparation method thereof. The special fertilizer comprises the following effective components in parts by mass: 15-22 parts of nitrogen, 5-10 parts of phosphorus pentoxide, 10-15 parts of potassium oxide, 0.1-0.3 part of zinc, 0.4-0.6 part of magnesium, 0.2-0.3 part of molybdenum, 1-2 parts of dicyandiamide and 5-10 parts of humic acid. The long-lasting special fertilizer for the rubber tree disclosed by the invention is reasonable in formula and high in service efficiency; overall nutrition required for growth of the rubber tree is met; the disease resistance of the rubber tree is improved; diseases are reduced; a long-lasting effect is achieved; the application number can be reduced; time and labor are saved; meanwhile, soil can be improved; nutrient balance of the soil is ensured; the growth speed of the rubber tree is quickened by the application of fertilizer of which the dosage is best for growth of the rubber tree; the yield of dry rubber is improved; and sustainable production of rubber is achieved.

Owner:HAINAN GANFENG FERTILIZER

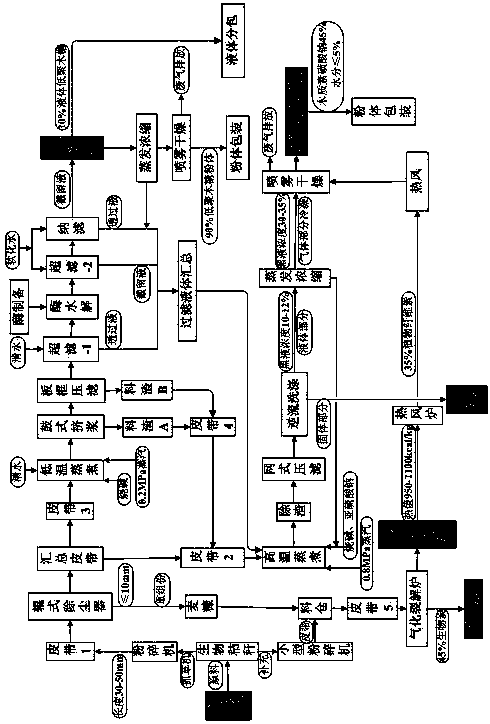

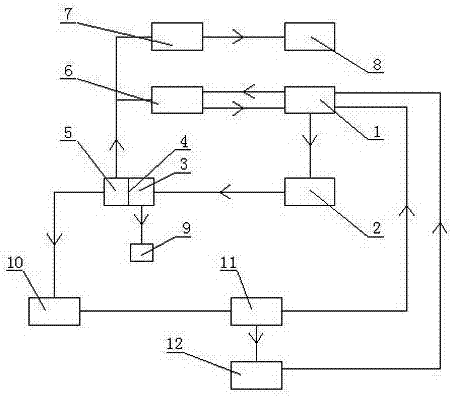

Five-coproduction process for comprehensively utilizing biological straw

PendingCN107586805AMaximize the use of scaleIncrease profitGaseous fuelsBiofuelsUltrafiltrationSlurry

The invention discloses a five-coproduction process for comprehensively utilizing biological straw, aiming at solving the technical problem of expanding the straw utilization scale. The process consists of three lines: the first line is used for producing xylooligosaccharide: smashing biological straw, introducing steam for boiling, passing through an ultrafiltration membrane-1 after filter pressing, passing through an ultrafiltration membrane-2 after enzymatic hydrolysis reaction, enabling penetrating fluid to be subjected to nanofiltration concentration so as to be concentrated by 3-5 timesto obtain the xylooligosaccharide; the second line is used for producing straw pulp and sodium lignosulfonate: smashing the biological straw, enabling the smashed biological straw and waste residue tobe subjected to pressurized high temperature boiling together, enabling obtained serous liquid to be subjected to filter pressing separation, and enabling solid matter obtained after separation to besubjected to adverse current cleaning to obtain wheat straw pulp; enabling black liquor and washing black water obtained after separation to evaporate and concentrate, then performing heat exchange via hot-blast air to obtain sodium lignosulphonate powder; and the third line produces biochar and combustible pyrolysis gas. On the premise of generating remarkable economical benefit, the five-coproduction process is friendly to environment and does not generate waste water so as to achieve zero discharging, solid waste does not exist, and the exhaust gas reaches the standard and is emitted.

Owner:临颍路得生物科技有限公司

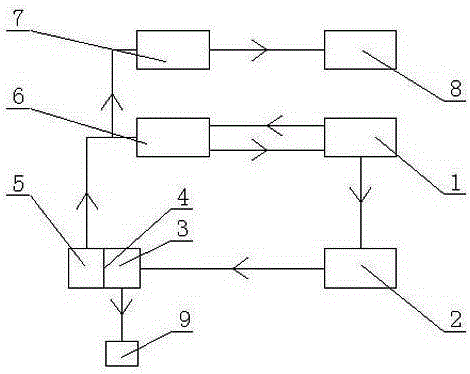

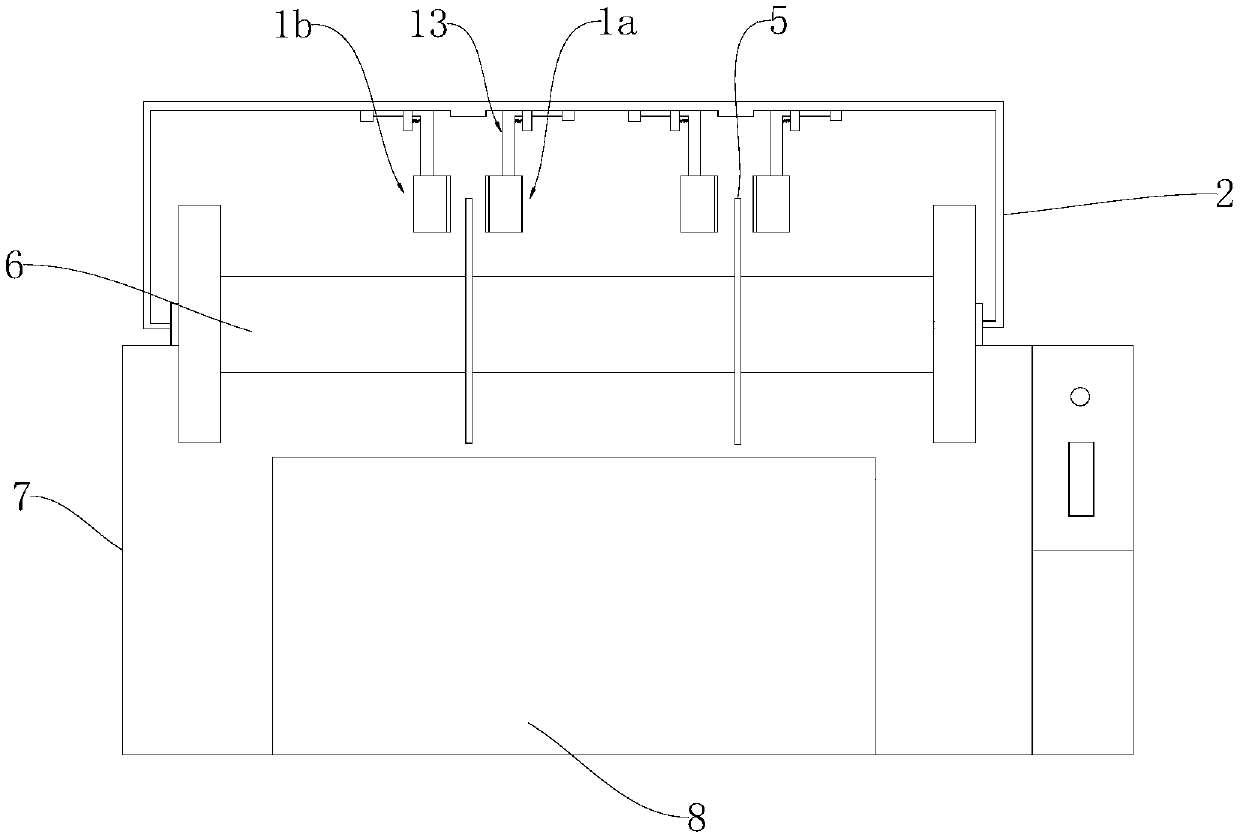

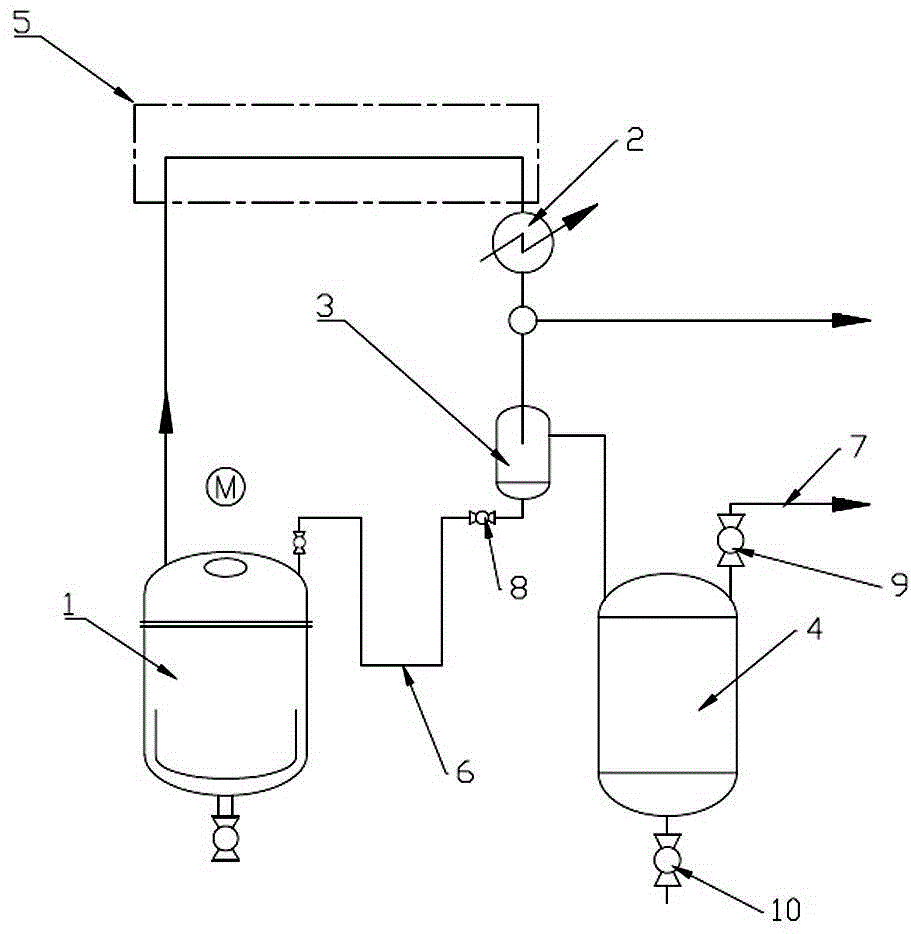

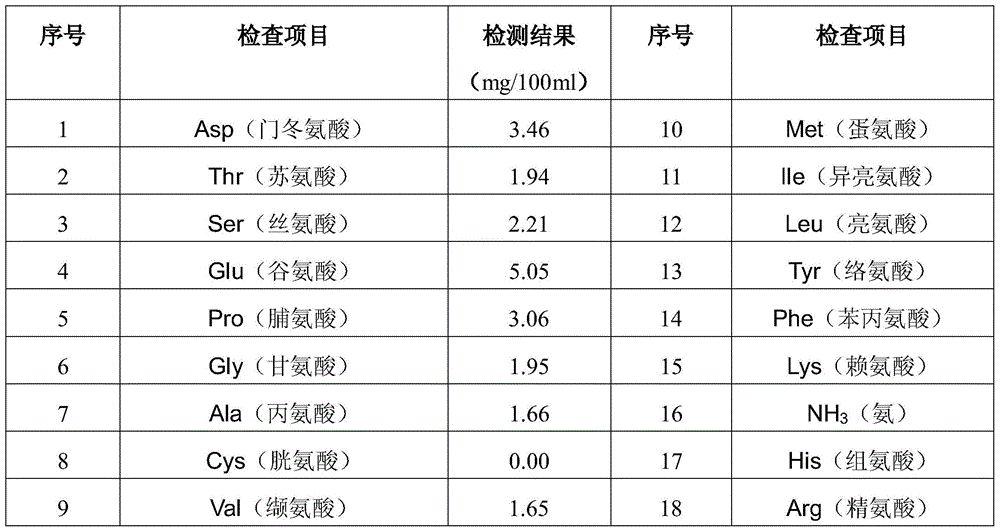

System for circulating and regenerating waste acidic etching solutions with tail gas treatment function

The invention discloses a system for circulating and regenerating waste acidic etching solutions with a tail gas treatment function. The system comprises an etching solution treatment system and a chlorine gas recycling system, wherein the etching solution treatment system comprises an etching production line (1), a mother solution storage tank (2), an electrolytic tank and a dissolving and absorbing system (6); the electrolytic tank comprises a cathode tank (3) and an anode tank (5); the mother solution storage tank (2), the cathode tank (3), the anode tank (5) and the dissolving and absorbing system (6) are connected with one another in sequence; the etching production line (1) is connected with the mother solution storage tank (2) and the dissolving and absorbing system (6) respectively; the chlorine gas recycling system comprises a gas inlet system (7) and a tail gas treatment system (8); the anode tank (5), a gas washing system (7) and the tail gas treatment system (8) are connected with one another in sequence. The system has the beneficial effects that the system can be used for treating the waste acidic etching solutions, the off-line production can be implemented, the cost can be reduced, the resources can be saved, and the environmental pollution can be avoided.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Fructose rosa roxburghii juice suspending beverage and production method thereof

The invention discloses a fructose rosa roxburghii juice suspending beverage and a production method thereof. The production method includes: adding a composite clarification agent into rosa roxburghii juice to obtain clarified rosa roxburghii juice; then adding 8%-20% of fructooligosaccharide and a water chestnut peel extract, conducting seasoning with citric acid, then performing refrigeration to remove precipitate to obtain rosa roxburghii clear juice; and finally adding solid juice granules and semisolid juice granules prepared in advance into the rosa roxburghii clear juice, with the weight ratio of the rosa roxburghii juice, the solid juice granules and the semisolid juice granules being 3:1-3:1-3, and mixing the materials uniformly to obtain the fructose rosa roxburghii juice suspending beverage. The beverage produced by the method provided by the invention is orange yellow, has a VC content of 500-2000mg / 100ml, and a SOD content of 2000-6000 IU / 100ml. Being sweet and delicious, and rich in nutrition, the fructose rosa roxburghii juice suspending beverage includes three states: full solidified state, semi-solidified state and liquid state, and is suitable for mass consumers including diabetic patients to drink.

Owner:GUANGXI RUIQIKANG BEVERAGE

Soil-less lawn and its cultivation process

InactiveCN1486586ALow costReduce production processAgriculture gas emission reductionCultivating equipmentsSustainable productionGreening

The present invention aims at providing one kind of soil-less lawn blanket with low cost, easy-to-obtain cultivation medium and high survival rate and its cultivation process. The present invention features that on water-maintaining and penetrating cultivation medium, hybrid propagula are planted and watered. The present invention can produce lawn continuously in less water consumption for different uses, such as temporarily indoor spreading, roof greening, etc.

Owner:宁德市农业科学研究所

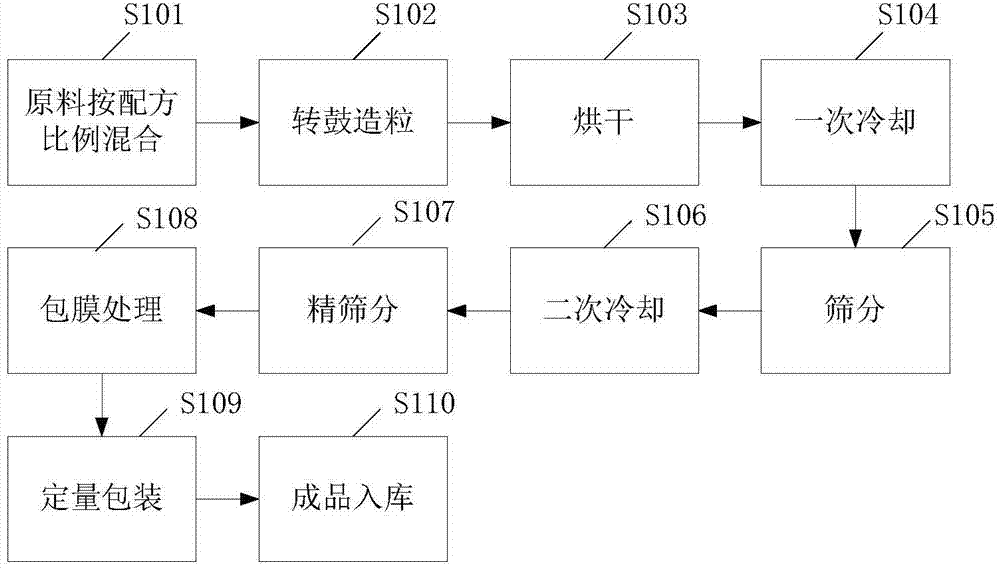

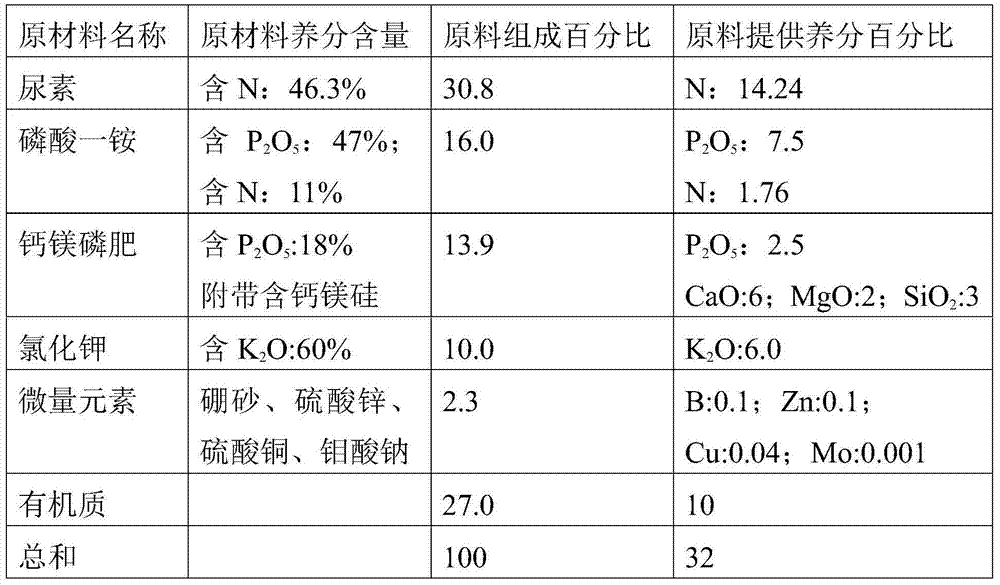

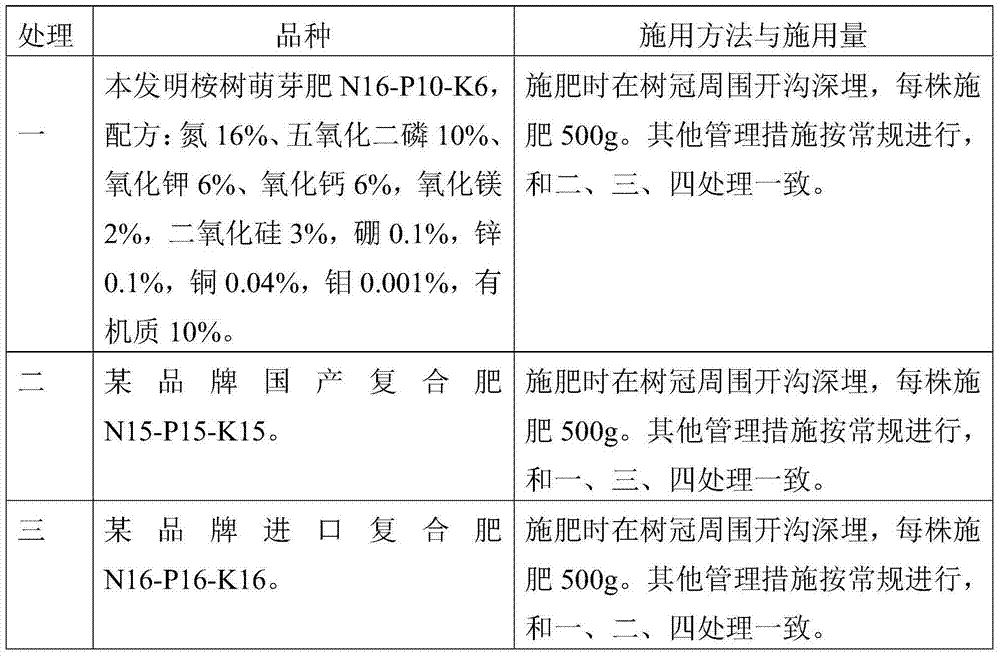

Eucalyptus germination fertilizer and fertilizer applying method thereof

ActiveCN103771968AComprehensive nutritionThe ratio is scientific and reasonableFertilising methodsFertilizer mixturesNutrientFertilizer

The invention discloses a eucalyptus germination fertilizer which is used for fertilizing a second generation of sprout forest of eucalyptus. The eucalyptus germination fertilizer is prepared from the raw materials of major elements of nitrogen, phosphorus and potassium, and trace elements of calcium, magnesium, silicon, boron, zinc, copper and molybdenum through processes of crushing, mixing, pelleting, and the like, wherein the content of nitrogen is 14-22 percent, the content of phosphorus pentoxide is 7-15 percent, the content of potassium oxide is 4-12 percent, the content of calcium oxide is 5-12 percent, the content of magnesium oxide is 1-5 percent, the content of silicon dioxide is 2-5 percent, the content of boron is 0.01-1 percent, the content of zinc is 0.01-1 percent, the content of copper is 0.01-1 percent, and the content of molybdenum is 0.001-0.1 percent. Correspondingly, the invention further discloses a fertilizing method of the eucalyptus germination fertilizer. By adopting the eucalyptus germination fertilizer, various nutrients necessary for the germination and growth of eucalyptus can be met, the fast-growing advantage is fully developed, unnecessary waste of fertilizer nutrients can be reduced, properties of disease resistance, wind resistance and cold resistance of the eucalyptus are enhanced, and scientific fertilization is realized.

Owner:GUANGDONG DAYI AGRI FORESTRY ECOLOGY TECH

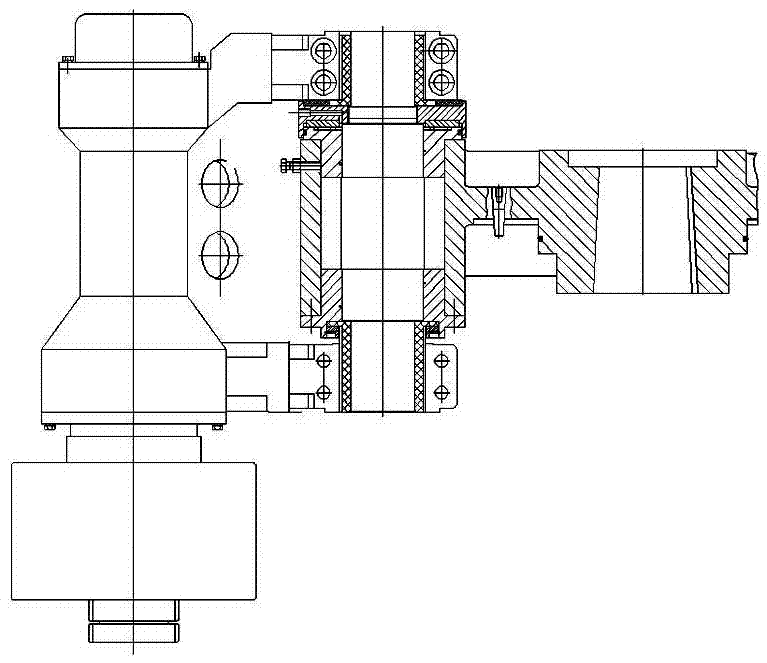

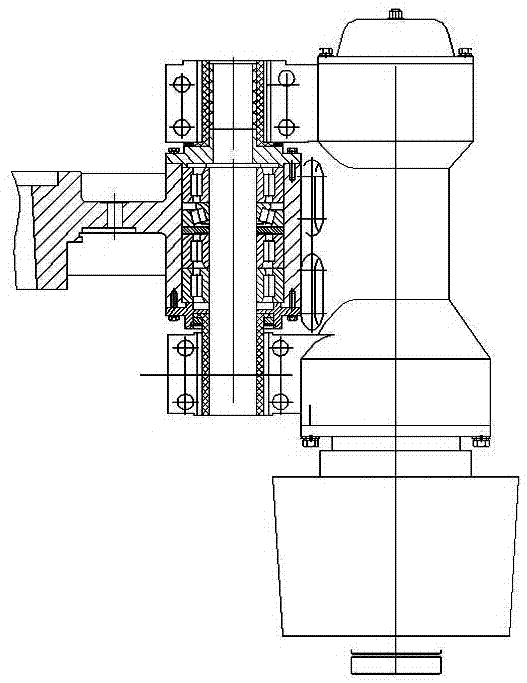

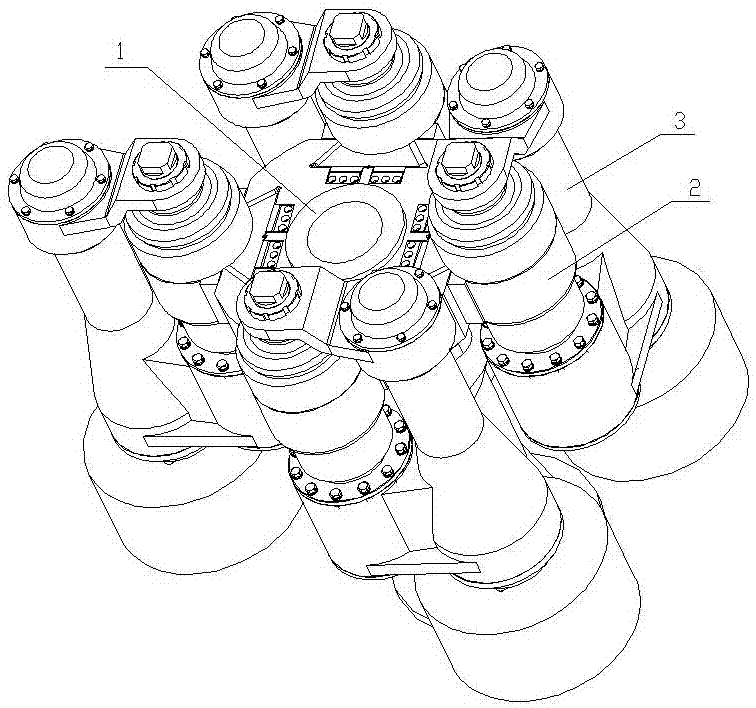

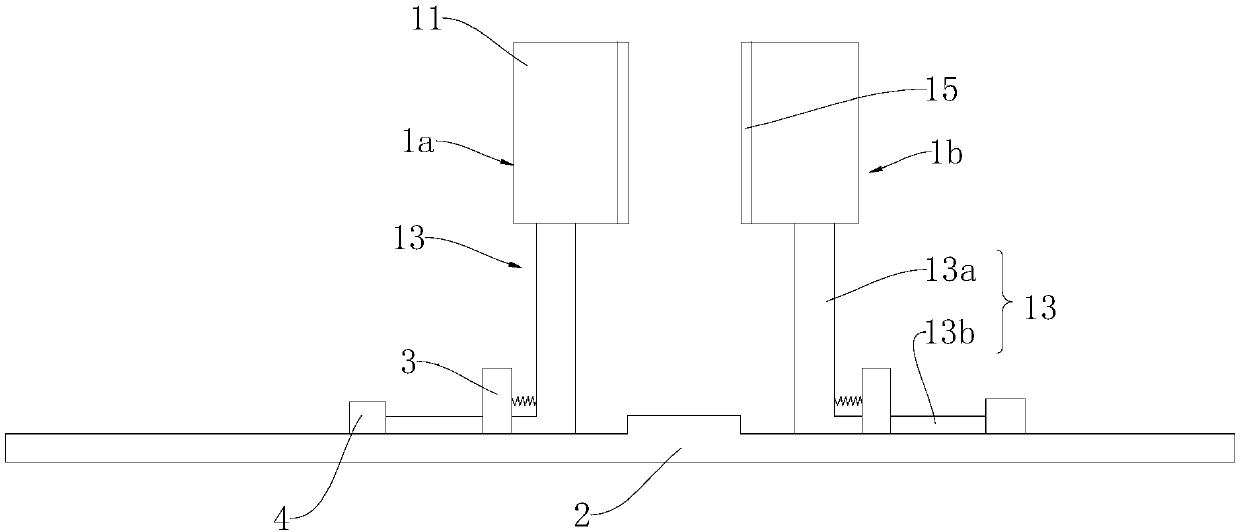

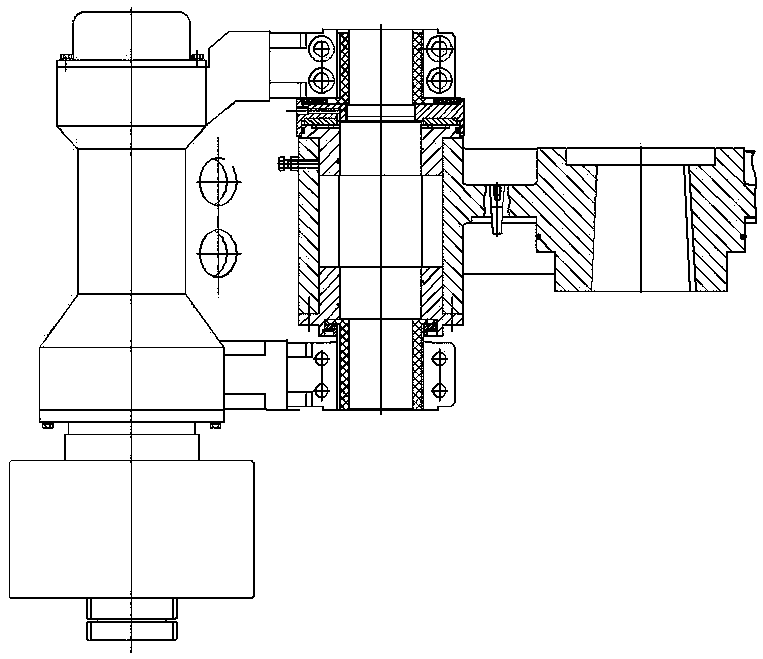

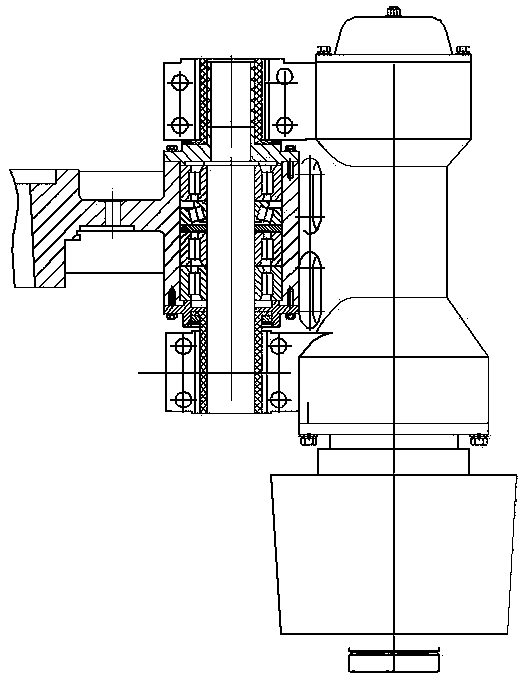

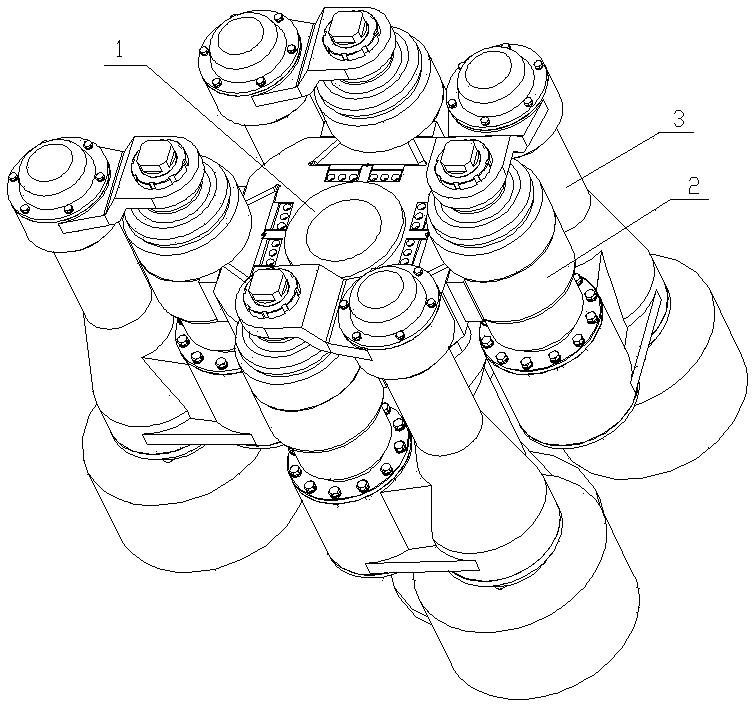

Efficiency damped and sealed vertical mill

ActiveCN105435909AGuaranteed tightnessAchieving sustainable productionEngine sealsNon-rotating vibration suppressionSustainable productionWear resistant

The invention discloses an efficiency damped and sealed vertical mill. The efficiency damped and sealed vertical mill comprises a star rack and a mill roller assembly, wherein the mill roller assembly works under the driving action of a suspension swing arm mechanism; the suspension swing arm mechanism comprises a vertical shaft arranged in a through hole of a dovetail slotted disc, a gravity support device connected with the mill roller assembly is arranged at the top of the vertical shaft, and a rotating assembly is arranged on the vertical shaft; the rotating assembly comprises an upper bearing arranged in a bearing cavity at the lower part of the vertical shaft in a sleeving manner, a wear-resistant sleeve and a lower bearing, and the inner hole wall of an upper bearing gland buckled on the upper bearing extends upwards along the vertical shaft so as to form a jacket; and the bottom of the dovetail slotted disc of the star rack is fixedly connected with a seal sleeve, and the seal sleeve extends downwards and is wrapped outside the jacket; and upper and lower oil seals and upper and lower seal steel discs are arranged in an annular cavity formed between the inner wall of the seal sleeve and the outer wall of the jacket, and a grease seal cavity is formed between the upper and lower oil seals. The efficiency damped and sealed vertical mill can ensure the high tightness of a bearing housing, is high in system stability, is low in maintenance rate, and can realize continuous production for users. Compared with the same class of machines, the efficiency damped and sealed vertical mill can increase the yield by 30%.

Owner:HENAN LIMING HEAVY IND SCI & TECH +1

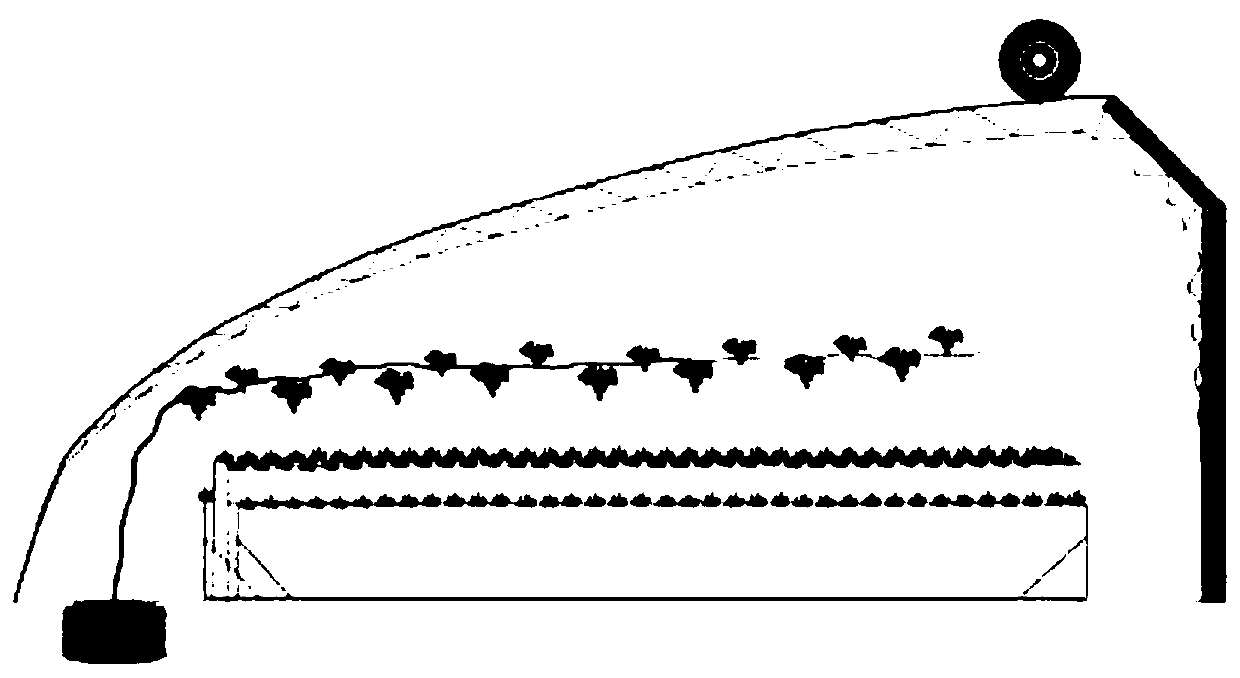

Single-layer double-arm factory-shaped grape shaping method

InactiveCN110178635AEasy to mechanizeIncrease productionCultivating equipmentsHorticulture methodsWine industryShoot

The invention relates to the technical field of grape cultivation, in particular to a single-layer double-arm factory-shaped grape shaping method. The method is suitable for soil-burying cold protection and mechanical operation, and a planting method simple and easy to operate, high in mechanization degree and capable of achieving high yield is provided for the development of grape and wine industries. According to the technical scheme adopted by the invention, the method comprises the steps of pruning of branch arm main vines, a trellis surface and short shoots, wherein two branch arm main vines are adopted; the height of the trellis surface is 1.40 meters, and the width of the trellis surface is 1 meter; the short shoots are pruned to retain 2-3 buds for pruning in winter.

Owner:NORTHWEST A & F UNIV

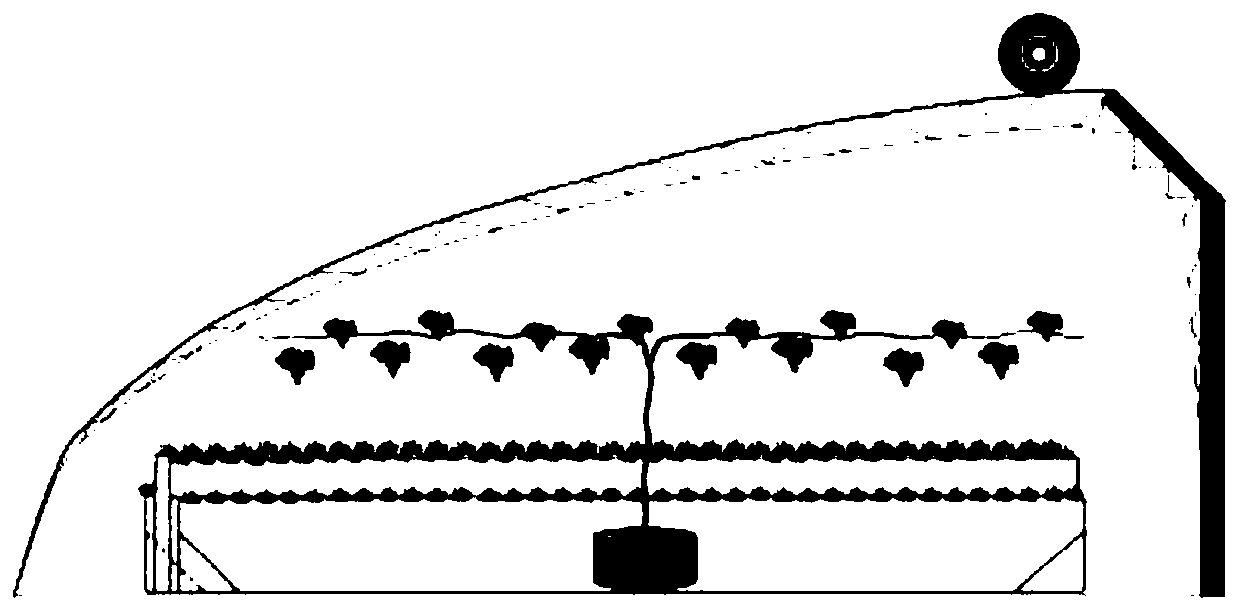

Interplanting method of root-limited grape and floor stand strawberry

InactiveCN110115193ALower economic returnsAchieve continuous outputCultivating equipmentsFruit crop cultivationFragariaEngineering

The invention provides an interplanting method of root-limited grape and floor stand strawberry. Reasonable interplanting of the root-limited grape and the floor stand strawberry is a cultivation modewhich is more modernized and intelligent and is a powerful combination, this is because that root systems of the root-limited grape and the floor stand strawberry are not in a same soil space, do notaffect each other and are free of competition for nutrient, and growth of the root-limited grape and the floor stand strawberry can be regulated by controlling water and nutrient through advanced equipment. The root-limited grape and the floor stand strawberry are interplanted for cultivation for the first time to form a root-limited grape and floor stand strawberry interplanting technical scheme, winter dormancy period is put forward creatively, grape trunks are paint-dried to avoid high-temperature dehydration death of facility grape, and accurate water and fertilizer control on each of thegrape and the strawberry can be realized.

Owner:SHANDONG ACAD OF GRAPE

Vegetable special fertilizer and preparation method and application thereof

PendingCN110372438ALong-lasting supply balanceIncrease supplyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiotechnologyContinuous cropping

The invention discloses a vegetable special fertilizer and a preparation method and application thereof. The vegetable special fertilizer includes functional bacteria, bacteriostatic and antiviral agents and mixed mineral particle carriers; the functional bacteria and the bacteriostatic and antiviral agents are adsorbed in the mixed mineral particle carriers, the functional bacteria include high-efficiency nitrogen-fixing bacteria, phosphate solubilizing bacteria and potassium bacteria, and the bacteriostatic and antiviral agents are laminarin and chlorogenic acid. The vegetable special fertilizer has the functions of nitrogen fixing, phosphate-resolving, and potassium-resolving, one time application can meet the nutritional requirements of vegetables for nitrogen, phosphorus and potassiumin the whole growing season, the fertilizer effect is long-lasting, nutrient supply is balanced, the soil is improved, continuous cropping obstacles are overcome, disease resistance of plants is enhanced, the environment is friendly, the yield and quality of vegetables are improved, and the sustainable production of high-quality vegetables is realized.

Owner:山东慧泰华生物技术有限公司

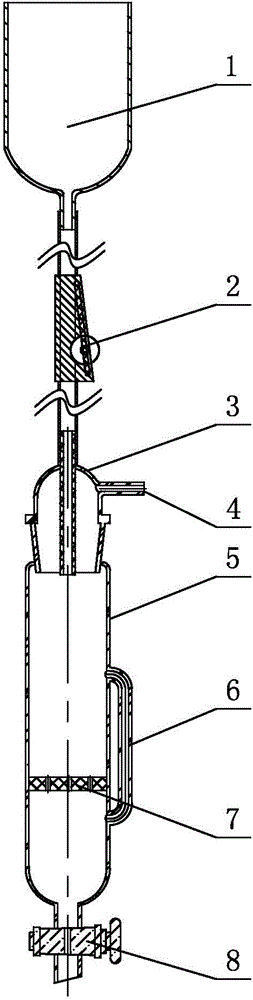

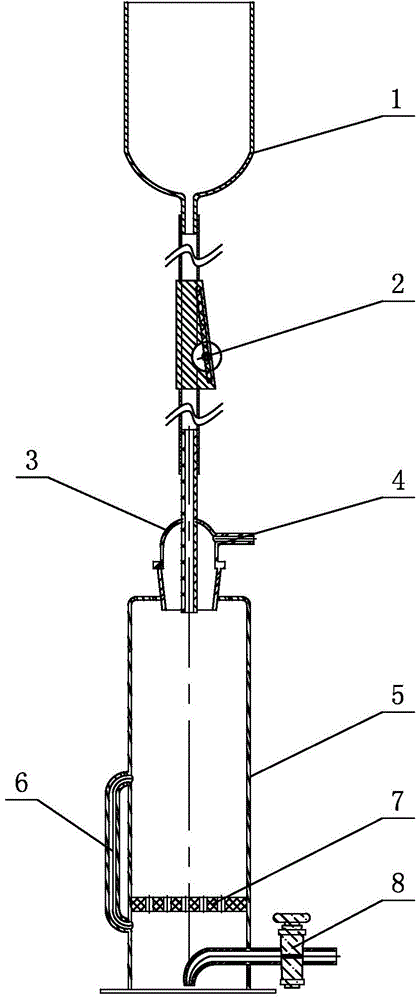

Gas velocity adjustable solid-liquid reactive gas generator and method thereof

ActiveCN104399411AIncrease contact surfaceAchieving sustainable productionGas generation devicesLiquid wasteSustainable production

The invention relates to a gas velocity adjustable solid-liquid reactive gas generator and a method thereof. According to the method, a reaction liquid is added drop by drop into a reactor through a liquid pipettor from above a solid reactant; the reaction liquid flows downward and fully contacts with and completely reacts with the solid reactant so as to generate a gas; the gas generated from the reaction is discharged above the solid reactant; and a reaction effluent flows through a sieve plate and enters an effluent chamber. By adjusting a liquid adding regulating valve, dropping speed of the reaction liquid is controlled so as to adjust generation speed of the gas. Air pressure between a reaction chamber and the effluent chamber is adjusted through a pressure-equalizing pipe. By stopping dropping the reaction liquid, the reaction is terminated. According to the invention, continuous generation of a gas can be realized, and waste of a liquid reagent is little. After the reaction stops, the device is not under pressure, and there is no danger of acid liquor leakage or overflow. Control of reaction progress is safer and more convenient and reliable.

Owner:陕西永兴环能科技股份公司

Large-scale breeding method for anagrus nilaparvatae

ActiveCN113180011AAchieve high volumeIncrease production capacityHorticulture methodsPlant protectionAnimal scienceBrown planthopper

The invention relates to the technical field of insect feeding, and discloses a large-scale breeding method for anagrus nilaparvatae. The large-scale breeding method comprises the following steps that 1, rice seedlings in a seedling stage are cultivated; 2, rice seedling pots obtained in the step 1 are moved into a first insect breeding cage placed in a brown planthopper inoculation and culture room, brown planthopper adults with the female-male ratio being 1 to 1 are inoculated into the first insect breeding cage, and rice seedling pots with brown planthopper eggs are produced; 3, the rice seedling pot with brown planthopper eggs obtained in the step 2 are transferred into a bee-keeping cage, and anagrus nilaparvatae with a male-female ratio of 1 to (0.5-1) is inoculated into the bee-keeping cage; and 4, bee pupae are collected, specifically, the rice seedlings with anagrus nilaparvatae in a pre-pupal stage are put into a refrigerator at 4 DEG C for cold storage, and adult bees are collected. According to the large-scale breeding method for the anagrus nilaparvatae, large-batch and continuous production of the anagrus nilaparvatae can be achieved, and the adult anagrus nilaparvatae can be rapidly obtained to prevent and control rice planthoppers by refrigerating and storing the rice seedlings with the anagrus nilaparvatae in the pre-pupal stage.

Owner:SUN YAT SEN UNIV

Special concentrated water-soluble fertilizer for blueberries as well as preparation method and application method of special concentrated water-soluble fertilizer

InactiveCN112457098APromote root growthIncrease resistanceMagnesium fertilisersAlkali orthophosphate fertiliserAmmonium sulfateNutrient

The invention provides a special concentrated water-soluble fertilizer for blueberries as well as a preparation method and an application method of the special concentrated water-soluble fertilizer, wherein the special concentrated water-soluble fertilizer is prepared from the following components: a macroelement nutrient solution A and a trace element nutrient solution B, wherein the macroelementnutrient solution A comprises 1.2-4.80 mol / L of ammonium sulfate, 0.6-2.40 mol / L of calcium nitrate tetrahydrate, 0.4-1.60 mol / L of potassium nitrate, 0.20-0.80 mol / L of magnesium sulfate and 0.20-0.80 mol / L of monopotassium phosphate; and the trace element nutrient solution B comprises 0.20 mol / L-0.60 mol / L of manganese sulfate, 0.10 mol / L-0.50 mol / L of boric acid, 0.005 mol / L-0.015 mol / L of copper sulfate, 0.05 mol / L-0.15 mol / L of zinc sulfate, 0.005 mol / L-0.015 mol / L of sodium molybdate, 0.10 mol / L-0.50 mol / L of ferrous sulfate and 0.10 mol / L-0.50 mol / L of ethylene diamine tetraacetic acid. According to the method, the requirements of blueberries for nutrient elements and the physical and chemical properties of soil are comprehensively considered, and the pH value and porosity of soilimprovement in the production process can be continuously stabilized. Compared with a traditional fertilization mode, the fertilizer investment is small, the absorption and utilization rate is high, soil protection is better facilitated, and sustainable production of blueberries is achieved.

Owner:四川省农业科学院经济作物育种栽培研究所

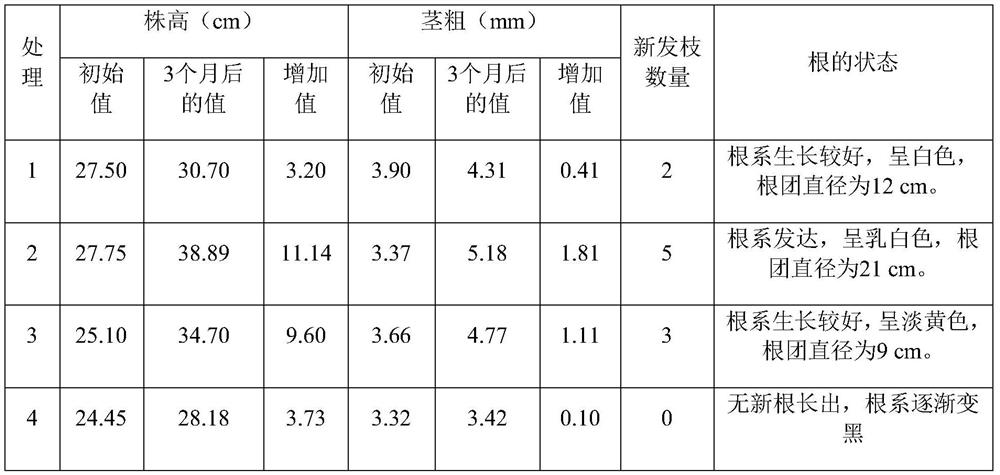

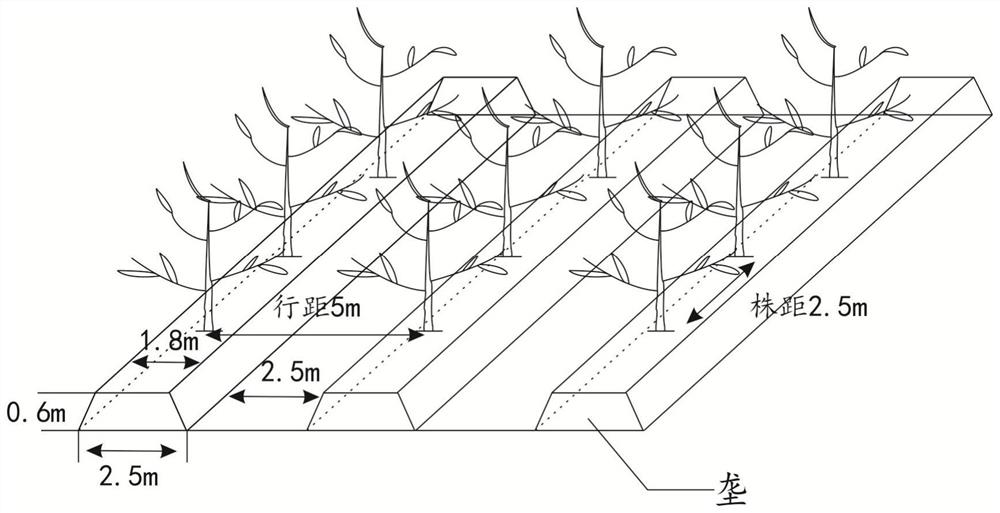

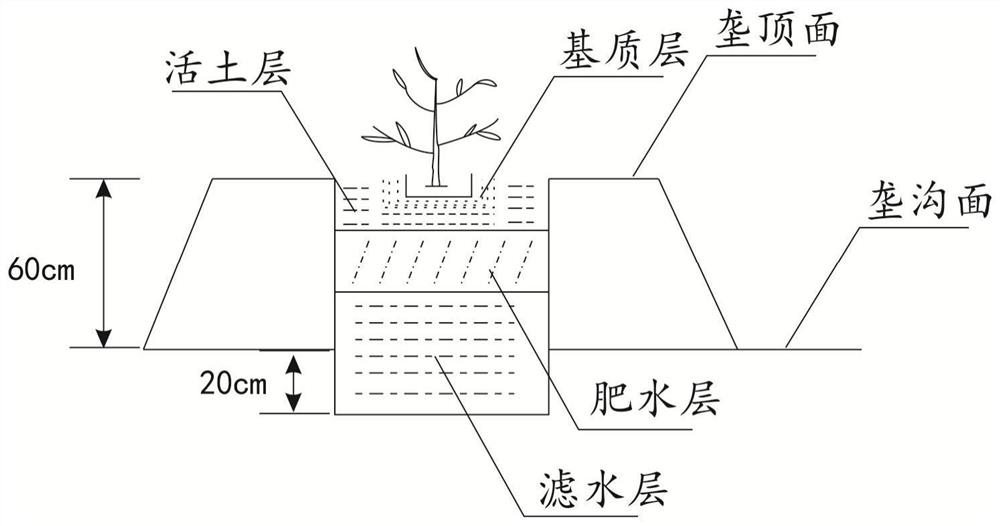

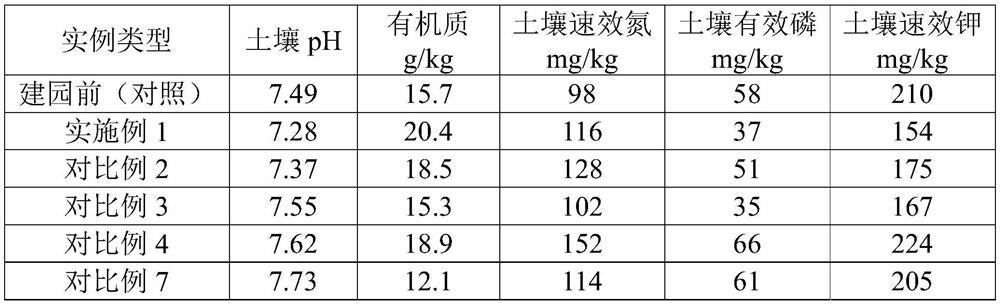

Method for quickly forming citrus orchard

ActiveCN113261465AFacilitates downward stretchEasy to stretchFertilising methodsAgriculture gas emission reductionAgricultural engineeringDisease damage

The invention discloses a method for quickly forming a citrus orchard, and belongs to the technical field of fruit tree cultivation. The method comprises the following steps: 1, strong seedling selection; 2, mechanical garden building; 3, rhizosphere soil improvement; 4, fertilizer and water management; 5, shaping without pruning; 6, effective control for pest and disease damage; and 7, tree disk covering. According to the method, basic conditions are created for rapid expansion of root systems in a mode of preferably selecting strong seedlings and locally improving soil in a root zone, nutrient supply in the citrus seedling stage is met, and the tedious procedure of applying base fertilizer in autumn in the seedling stage is reduced; a garden building mode of deep ditch, wide compartment and single-row ridging facilitates mechanical light operation, and the later-stage management and protection cost is greatly reduced; by application of the technology of shaping without pruning, rapid outward expansion of plant crowns is realized, and nutrient waste caused by pruning is avoided; and high-efficiency management in the seedling stage is achieved through pest and disease key period control and formulated fertilization technologies, the dosage of chemical fertilizers and pesticides and input of labor force are remarkably reduced, the plant growth vigor and the fruiting period are 2-3 years earlier than those in the prior art, and early fruiting, high yield and stable yield of fruit trees and sustainable production of soil are achieved.

Owner:NANCHONG ACAD OF AGRI SCI

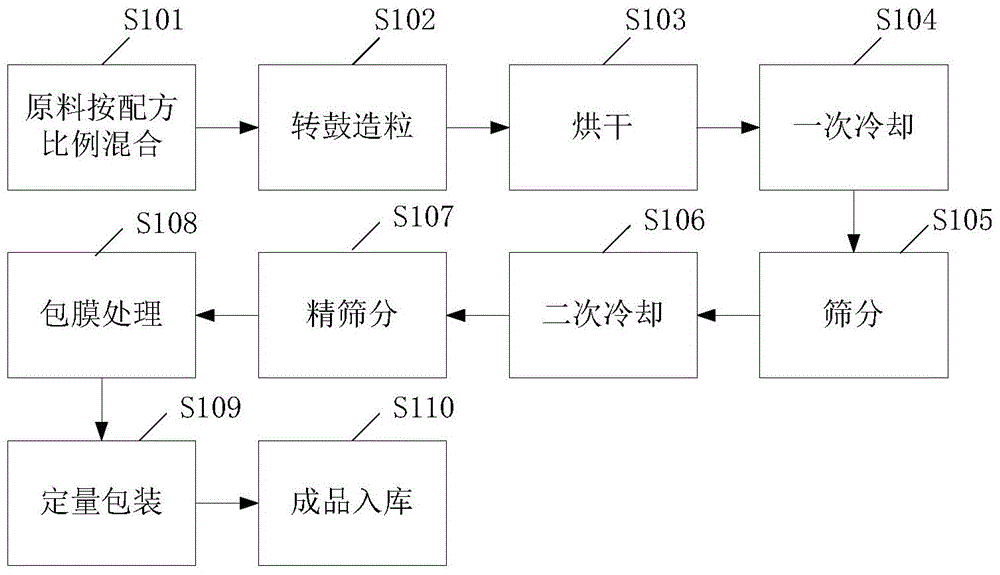

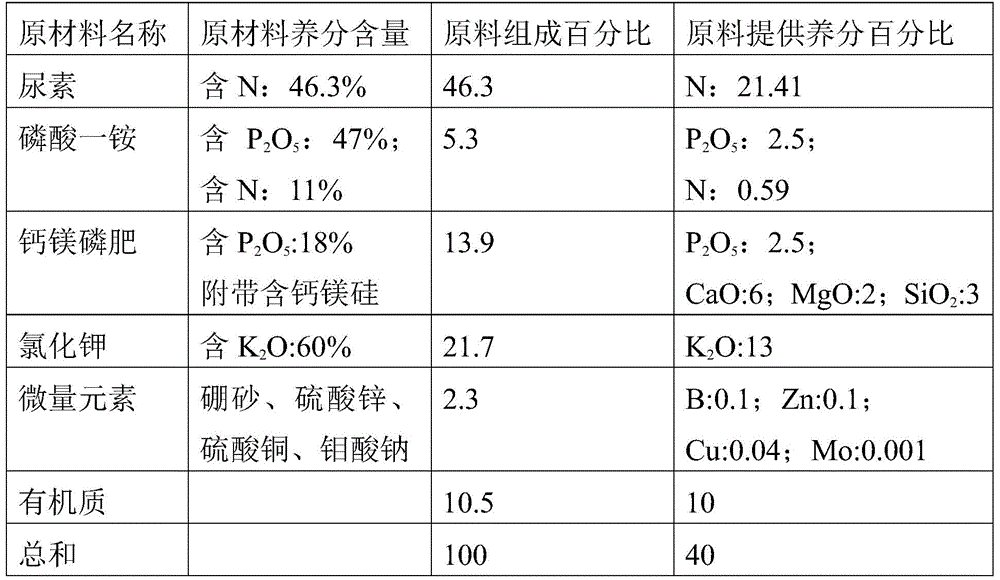

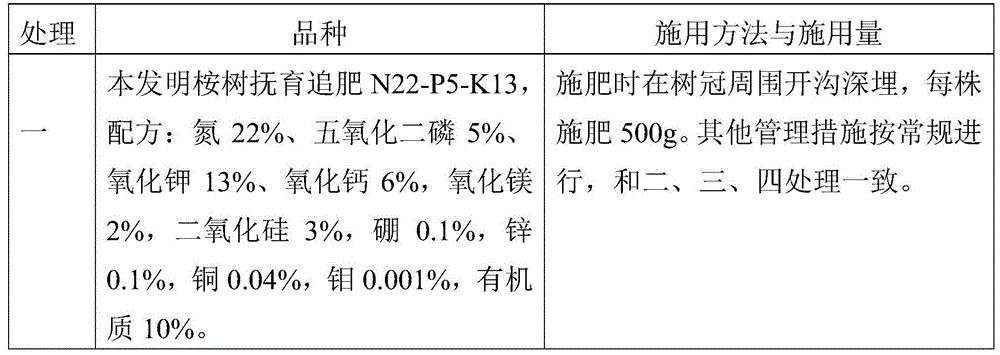

Eucalyptus tending and top dressing and its fertilizing method

ActiveCN103771969BComplete ratioThe ratio is comprehensive and the ratio is scientific and reasonableFertilising methodsFertilizer mixturesPotassiumSilicon dioxide

The invention discloses topdressing for fostering eucalyptus. The topdressing is used for fertilizing eucalyptus plantation, and is prepared from raw materials of macroelements of nitrogen, phosphorus and potassium, and microelements of calcium, magnesium, silicon, boron, zinc, copper and molybdenum by the processes of crushing, mixing, pelletizing and the like; the topdressing for fostering eucalyptus comprises the following effective components by weight percent: 18-32% of nitrogen, 3-12% of phosphorus pentoxide, 8-22% of potassium oxide, 5-12% of calcium oxide, 1-5% of magnesium oxide, 2-5% of silica, 0.01-1% of boron, 0.01-1% of zinc, 0.01-1% of copper, and 0.001-0.1% of molybdenum. Correspondingly, the invention also discloses a fertilizing method of the topdressing for fostering eucalyptus. By adopting the topdressing, kinds of necessary nutrients for eucalyptus growth can be met, the fast-growing advantages are fully developed, unnecessary waste of fertilizer nutrients can be reduced, the disease resistance, the wind resistance and the cold resistance of the eucalyptus can be enhanced, and scientific fertilization can be achieved.

Owner:GUANGDONG DAYI AGRI FORESTRY ECOLOGY TECH

Slip-casting inorganic insulation board and preparation method thereof

ActiveCN103086739AGood fire resistanceGood strengthCeramicwareHydroxypropylmethyl cellulosePolypropylene

The invention relates to a slip-casting inorganic insulation board and a preparation method thereof. The slip-casting inorganic insulation board comprises the following components in parts by weight: 500-600 parts of high-alumina cement, 100-200 parts of ordinary silicon cement, 100-200 parts of desulfurized gypsum, 300-450 parts of glazed hollow bead, 3 parts of hydroxypropyl methylcellulose, 1 part of 6mm-PP (Polypropylene) fiber, 8 parts of glass fiber, 4 parts of non-woven fiber, 4 parts of animal protein foaming agent and 1000 parts of water. The slip-casting inorganic insulation board has the advantages of high strength, difficulty in pulverization, low water absorption, stronger cohesive force with walls, difficulty in dropping, low heat conductivity coefficients, and very good energy-saving heat preservation effect, and therefore, the slip-casting inorganic insulation board simultaneously has two functions of fire retardancy and energy-saving heat preservation, thus buildings are safe and energy-saving and meet the requirements of energy conservation and environmental protection and green buildings.

Owner:上海复培新材料科技有限公司

Long-lasting special fertilizer for rubber tree and preparation method thereof

InactiveCN103408384BFull of nutritionImprove disease resistanceFertilizer mixturesSoil scienceNutrition

The invention discloses a long-lasting special fertilizer for a rubber tree and a preparation method thereof. The special fertilizer comprises the following effective components in parts by mass: 15-22 parts of nitrogen, 5-10 parts of phosphorus pentoxide, 10-15 parts of potassium oxide, 0.1-0.3 part of zinc, 0.4-0.6 part of magnesium, 0.2-0.3 part of molybdenum, 1-2 parts of dicyandiamide and 5-10 parts of humic acid. The long-lasting special fertilizer for the rubber tree disclosed by the invention is reasonable in formula and high in service efficiency; overall nutrition required for growth of the rubber tree is met; the disease resistance of the rubber tree is improved; diseases are reduced; a long-lasting effect is achieved; the application number can be reduced; time and labor are saved; meanwhile, soil can be improved; nutrient balance of the soil is ensured; the growth speed of the rubber tree is quickened by the application of fertilizer of which the dosage is best for growth of the rubber tree; the yield of dry rubber is improved; and sustainable production of rubber is achieved.

Owner:HAINAN GANFENG FERTILIZER

Paper cutting machine with cleaning function

PendingCN107738475AQuality assuranceShorten production timePaper-makingBox making operationsProduction lineSustainable production

The invention discloses a paper cutting machine with a cleaning function, and relates to the field of paper product packaging and machining. The paper cutting machine comprises a cutting device and acleaning device; the cutting device comprises a support table, a cutting assembly and a conveying device, the cutting assembly is arranged above the support table, the conveying device is located below the cutting assembly, and the cutting assembly comprises a roller and a round blade arranged on the roller in a sleeving manner; the cleaning device comprises a power device and a cleaning part usedfor cleaning the round blade, the cleaning part comprises a first cleaning part body and a second cleaning part body, the first cleaning part body and the second cleaning part body are both in sliding connection with a fixing rod, and the first cleaning part body and the second cleaning part body are symmetrically arranged on the two sides of the round blade; and the first cleaning part body andthe second cleaning part body are both connected with a power device, and the power device is used for driving the first cleaning part body and the second cleaning part body to move in the same direction or in the opposite direction. By means of the paper cutting machine, the blade can be maintained and cleaned under the condition that normal production is not influenced, sustainable production ofa production line is guaranteed, meanwhile, the product yield rate is guaranteed, and the beneficial effects of being quick and saving time and labor are achieved.

Owner:四川祥发环保科技有限公司

Random-color anti-static ceramic tile and preparation method thereof

The invention discloses a random-color anti-static ceramic tile and a preparation method thereof. The random-color anti-static ceramic tile is prepared from the following raw materials in parts by weight: 10-13 parts of barium carbonate, 12-14 parts of zinc oxide, 3-5 parts of quartz, 14-15 parts of dolomite, 10-11 parts of water-washed soil, 46-49 parts of feldspar, 5-7 parts of talc, 30-34 partsof electrically conductive powder and 0.1-0.3 part of a coloring material. The situation that a ceramic tile is single in color is changed, the ceramic tile keeps good electric conductivity, a stableelectric conductive network is formed, the influence of metal oxide is reduced to the minimum, and sustainable production is realized.

Owner:佛山昕通新型材料有限公司

High-efficiency shock-absorbing and sealed vertical mill

ActiveCN105435909BGuaranteed tightnessAchieving sustainable productionEngine sealsNon-rotating vibration suppressionWear resistantSustainable production

The invention discloses an efficiency damped and sealed vertical mill. The efficiency damped and sealed vertical mill comprises a star rack and a mill roller assembly, wherein the mill roller assembly works under the driving action of a suspension swing arm mechanism; the suspension swing arm mechanism comprises a vertical shaft arranged in a through hole of a dovetail slotted disc, a gravity support device connected with the mill roller assembly is arranged at the top of the vertical shaft, and a rotating assembly is arranged on the vertical shaft; the rotating assembly comprises an upper bearing arranged in a bearing cavity at the lower part of the vertical shaft in a sleeving manner, a wear-resistant sleeve and a lower bearing, and the inner hole wall of an upper bearing gland buckled on the upper bearing extends upwards along the vertical shaft so as to form a jacket; and the bottom of the dovetail slotted disc of the star rack is fixedly connected with a seal sleeve, and the seal sleeve extends downwards and is wrapped outside the jacket; and upper and lower oil seals and upper and lower seal steel discs are arranged in an annular cavity formed between the inner wall of the seal sleeve and the outer wall of the jacket, and a grease seal cavity is formed between the upper and lower oil seals. The efficiency damped and sealed vertical mill can ensure the high tightness of a bearing housing, is high in system stability, is low in maintenance rate, and can realize continuous production for users. Compared with the same class of machines, the efficiency damped and sealed vertical mill can increase the yield by 30%.

Owner:HENAN LIMING HEAVY IND SCI & TECH +1

Pine tree controlled-release fertilizer for scientifically increasing yield and preparation technology thereof

InactiveCN109516874AThe ratio is scientific and reasonableReduce wasteCalcareous fertilisersMagnesium fertilisersChemistryFulvic acid

The invention discloses a pine tree controlled-release fertilizer for scientifically increasing yield and a preparation technology thereof and belongs to the technical field of fertilizer preparation.The pine tree controlled-release fertilizer for scientifically increasing yield comprises the following raw materials: urea, diammonium phosphate, potassium sulfate, calcium chloride, magnesium sulfate, manganese chloride, zinc chloride, sodium borate, fulvic acid, potassium polyacrylate, kieselguhr and coating material. The pine tree controlled-release fertilizer for scientifically increasing yield is prepared according to the following steps: pelletizing, drying, cooling, coating, and the like. According to the invention, the advantages of pine tree controlled-release fertilizer can be extremely utilized; cultivation of short-period industrial raw material forest of pine trees can be realized; the rotation period of industrial raw material forest of pine trees can be greatly shortened;mineral substances and nutrients brought by pine tree felling can be made up and nutrient balance of soil can be guaranteed; the maximal economic benefit can be acquired with the minimal fertilizer investment; the sustainable production of pie tree planting region can be realized.

Owner:GUANGXI FORESTRY RES INST

Recovery unit for excess hydroquinone in dhppa synthesis

InactiveCN103435451BHigh yieldNo pollutionOrganic chemistryOrganic compound preparationMethyl isobutyl ketoneSustainable production

The invention discloses a treatment device applied to recover excessive hydroquinone after DHPPA is synthesized. Especially, the recovery device comprises a solution flash evaporation kettle, a condenser, an oil-water separator and an extracting agent receiving tank, wherein an extracting agent MIBK (Methyl Isobutyl Ketone) and hydroquinone raffinate are contained in the solution flash evaporation kettle; the top of the solution flash evaporation kettle is connected with the top of the condenser through an evaporating pipe; the bottom of the condenser is connected with the top of the oil-water separator; the bottom of the oil-water separator is connected to the top of the solution flash evaporation kettle through a reflux pipe; the side wall of the oil-water separator is connected to the top of the extracting agent receiving tank through a delivery pipe; a vacuum channel is arranged at the top of the extracting agent receiving tank. The treatment device disclosed by the invention can be used for recycling the extracting agent, obtains sufficient hydroquinone, greatly increases the product yield, saves the cost and reduces the consumption; and the treatment device disclosed by the invention can not generate a large amount of waste water when in use and can not cause the environment pollution, thereby really realizing the environment-friendly and resource-saving sustainable production.

Owner:上海胤衡环境科技有限公司

A kind of fructose prickly pear juice suspension beverage and production method thereof

The invention discloses a fructose rosa roxburghii juice suspending beverage and a production method thereof. The production method includes: adding a composite clarification agent into rosa roxburghii juice to obtain clarified rosa roxburghii juice; then adding 8%-20% of fructooligosaccharide and a water chestnut peel extract, conducting seasoning with citric acid, then performing refrigeration to remove precipitate to obtain rosa roxburghii clear juice; and finally adding solid juice granules and semisolid juice granules prepared in advance into the rosa roxburghii clear juice, with the weight ratio of the rosa roxburghii juice, the solid juice granules and the semisolid juice granules being 3:1-3:1-3, and mixing the materials uniformly to obtain the fructose rosa roxburghii juice suspending beverage. The beverage produced by the method provided by the invention is orange yellow, has a VC content of 500-2000mg / 100ml, and a SOD content of 2000-6000 IU / 100ml. Being sweet and delicious, and rich in nutrition, the fructose rosa roxburghii juice suspending beverage includes three states: full solidified state, semi-solidified state and liquid state, and is suitable for mass consumers including diabetic patients to drink.

Owner:GUANGXI RUIQIKANG BEVERAGE

A method and system for recycling and regenerating acidic etching waste liquid with zero discharge

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

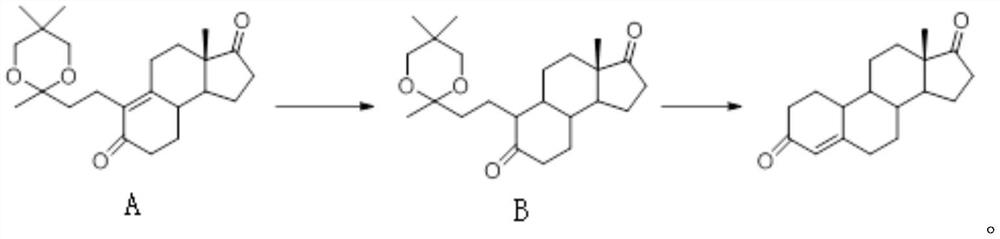

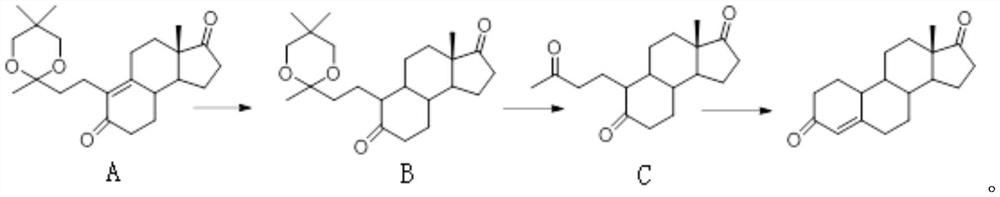

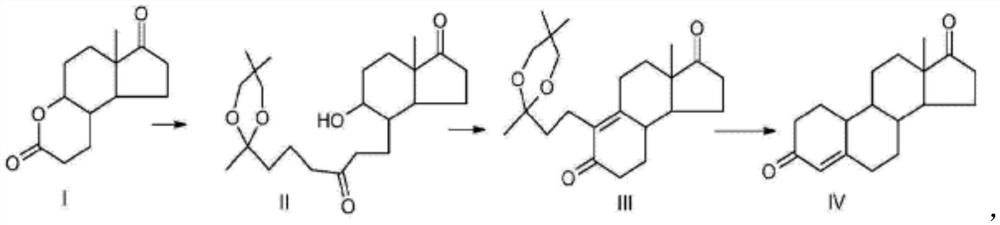

Preparation method of 19-nor-4-androstenedione

The invention belongs to the technical field of steroid hormone preparation, and particularly relates to a preparation method of 19-nor-4-androstenedione, which comprises the following steps: mixing a compound A, ethanol and pyridine, adding palladium on carbon, introducing hydrogen, and reacting to obtain a compound B; the compound B and isopropanol are mixed, an acid solution is added, the acid solution is a hydrochloric acid solution or a salt solution of alkali metal which is dissolved to be acidic, reaction and treatment are conducted, and 19-nor-4-androstenedione is obtained, the reaction route is as follows: the yield and purity of the product can be effectively improved, and the product is white.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

Improved T acid wastewater extraction process and preparation method of modified naphthalene dispersant or naphthalene water reducer

InactiveCN110330256ASolve the problem of excessive sodium sulfate contentAvoid pollutionWater/sewage treatment by extractionLiquid productWastewater

The invention discloses an improved T acid wastewater extraction process and a preparation method of a modified naphthalene dispersant or naphthalene water reducer. Specifically, the T acid wastewaterextraction process uses concentrated sulfuric acid to adjust the pH value of T acid wastewater, also utilizes an extractant to extract a waste T acid complex, and then performs back extraction through a back-extractant, thus obtaining waste T acid alkaline liquid with a sodium sulfate content of less than 10% and a recovered extractant. The recovered extractant can be repeatedly used for T acid wastewater extraction process, and the waste T acid alkaline liquid can be used for preparation of the undermentioned modified naphthalene dispersant or naphthalene water reducer. The preparation method of the modified naphthalene dispersant or naphthalene water reducer includes: subjecting naphthalene or methylnaphthalene to sulfonation reaction, adding the waste T acid alkaline liquid for hydrolysis reaction, and adding formaldehyde dropwise for condensation reaction, thus finally obtaining a modified naphthalene dispersant or naphthalene water reducer liquid product with a solid content of 30-50%.

Owner:华颢控股(集团)有限公司

A kind of harmless method for planting dendrobium officinale

InactiveCN109169019BReduce deliveryReduce pollutionSuperphosphatesExcrement fertilisersBiotechnologyPesticide residue

The invention provides a method for harmlessly planting Dendrobium officinale, comprising the following steps: S1. configuring growth medium; S2. selecting and preparing the soil; S3. cultivating and planting; S4. managing water and fertilizer; S5. managing diseases and insect pests. Among them, adding golden sunflower compound biological fertilizer and CM biological nitrogen-fixing fertilizer in the process of configuring the growth medium stage can effectively prevent and control snails, slugs and soil-borne diseases and insect pests that harm Dendrobium officinale, and in the stage of pest management, use photosynthetic bacteria, fertile Fertilizer No. 2 microbial soil amendment, anthrax fungus spirit, Huaguoshiqing No. 1, Pseudomonas fluorescens, snail shark pine oil molluscicide and other pure biological source insecticides and fungicides are used to prevent and control the growth of Dendrobium officinale, which not only solves the problem of The current planting of Dendrobium officinale urgently needs to solve bottlenecks such as prevention and control of snails and slugs and reduce pesticide residues.

Owner:广西有机农业研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com