Paper cutting machine with cleaning function

A cutting machine and cleaning technology, which is applied in the direction of papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of manual disassembly and cleaning of blades, occupying production time, etc., to save time, ensure quality, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

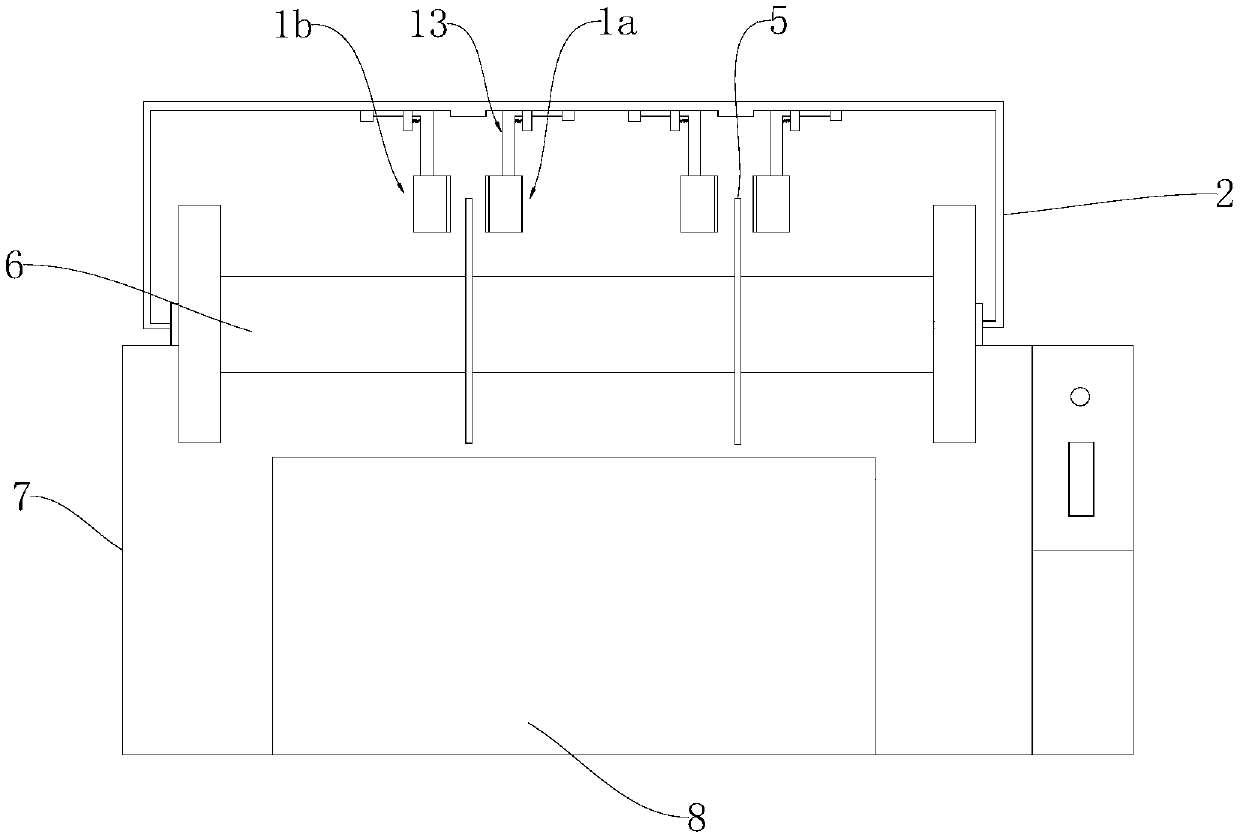

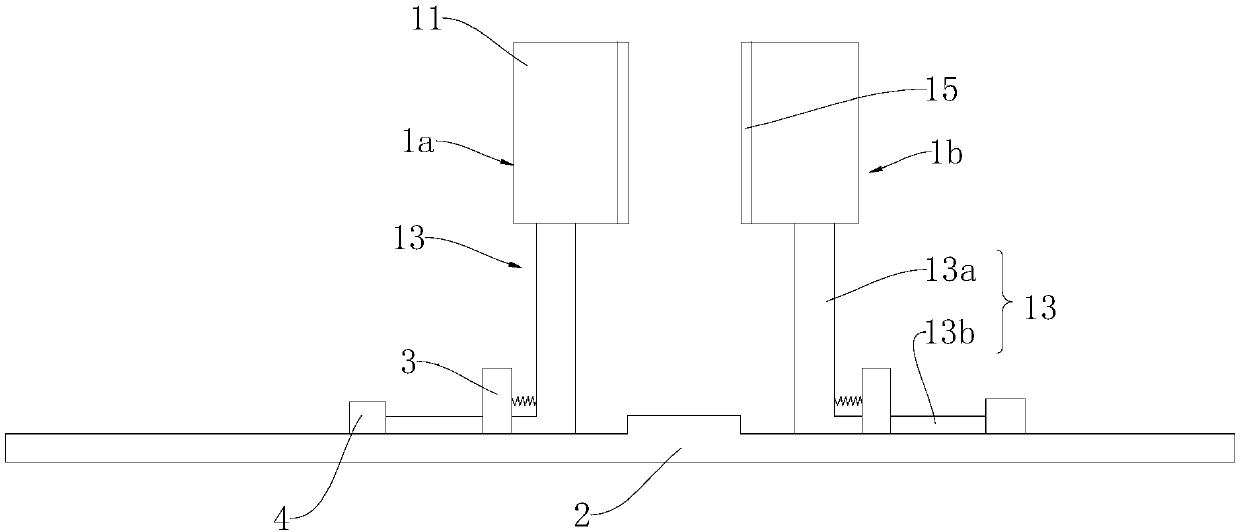

[0017] Please refer to figure 1 , the present embodiment provides a paper cutting machine with a cleaning function, which mainly includes a cutting device for cutting base paper and a cleaning device for cleaning the blade of the cutting device; the cutting device includes a support table 7, a cutting assembly and a conveying device 8, The cutting assembly is arranged above the support platform 7, and the conveying device 8 is located below the cutting assembly. The conveying device 8 is used to convey the paper, and the cutting assembly cooperates with it to complete the longitudinal cutting of the paper. The cutting assembly includes a drum 6 and a circular blade 5 sleeved on the drum 6, and at least one circular blade 5 is provided, and the number of the circular blades 5 and the distance between them are set according to the width of the specific production paper.

[0018] The cleaning device is fixedly connected with the support platform 7 through the fixed rod 2 . The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com