Efficiency damped and sealed vertical mill

A vertical grinding and high-efficiency technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems of reduced output of the mill, malfunction of the main shaft, and high maintenance rate, so as to ensure the sealing performance and reduce the maintenance rate. , the effect of high system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

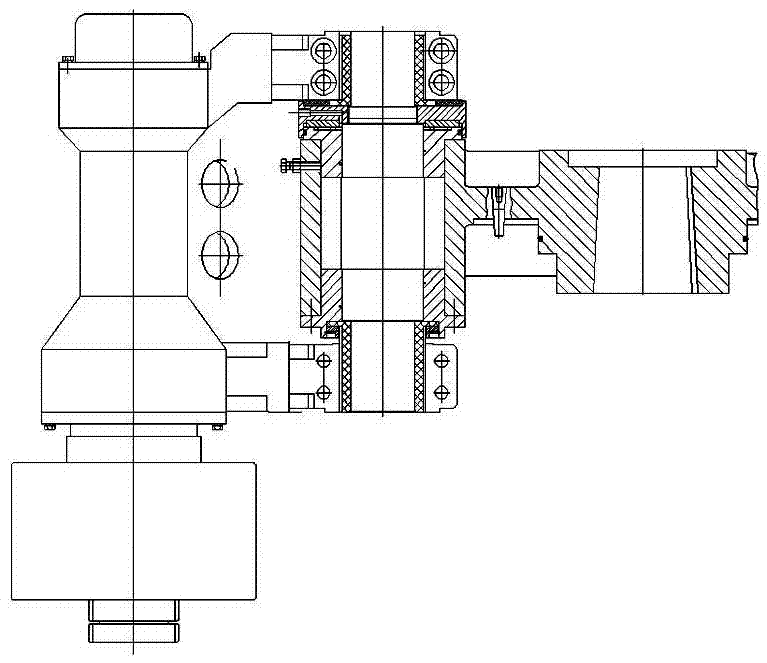

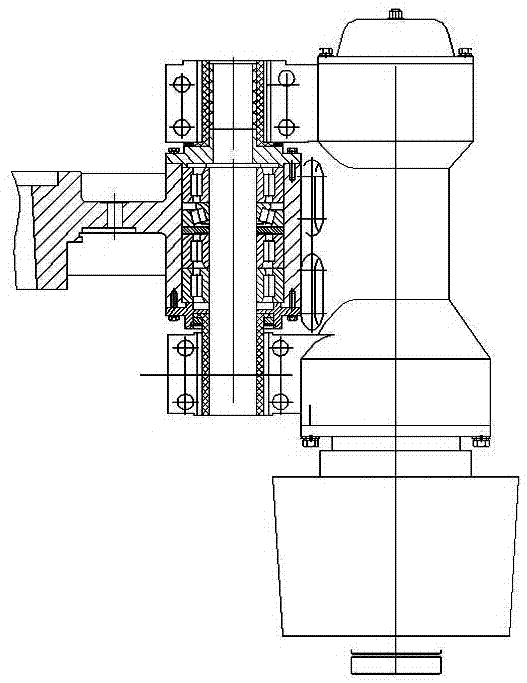

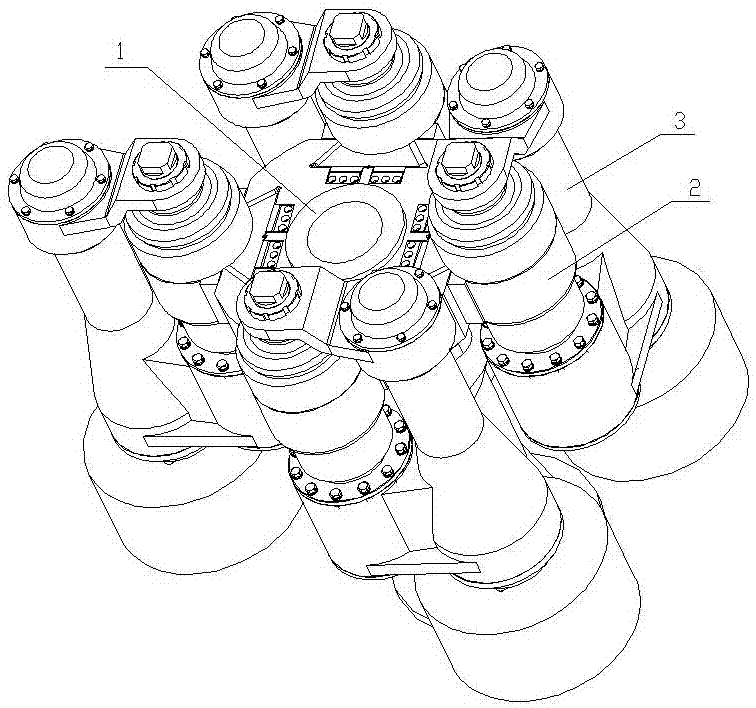

[0020] like image 3 , 4 , 4-1, the high-efficiency shock-absorbing and sealed vertical mill of the present invention includes a plum blossom frame 1 placed in the body and a device that is evenly arranged on the plum blossom frame and is driven by a swing arm mechanism 2 suspended by the plum blossom frame. The grinding roller assembly 3, the suspension swing arm mechanism 2 of the present invention includes a vertical shaft 2.1 arranged in the longitudinal through hole of the plum blossom frame dovetail groove plate 4, a rotating assembly with a shaft sealing device is arranged on the vertical shaft 2.1, and the top of the vertical shaft 2.1 A gravity support device connected to the grinding roller assembly 3 is provided;

[0021] The rotating assembly adopted in the present invention includes an upper bearing 2.2 and a lower bearing 2.3 set in the lower bearing chamber of the vertical shaft 2.1, a wear-resistant sleeve 2.4 is arranged between the upper bearing 2.2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com