Single-layer double-arm factory-shaped grape shaping method

A plant-shaped, double-arm technology, applied in the field of single-layer double-arm plant-shaped grape plastics, can solve the problems of difficult mechanized operations, cumbersome burying and unloading, and low output, achieving sustainable production and reducing labor intensity And the harm of diseases and insect pests, the effect of simple pruning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

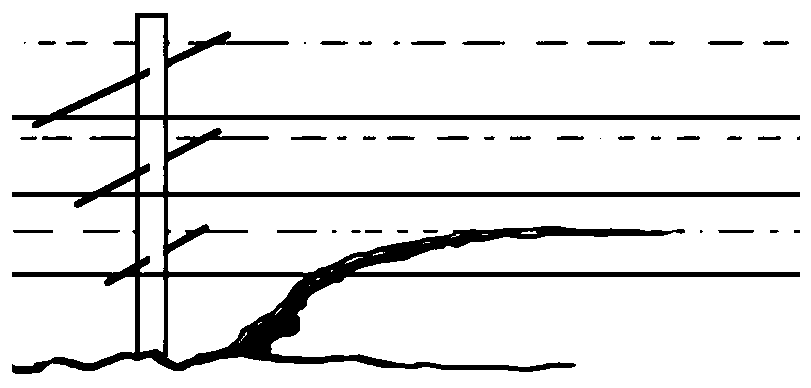

[0027] (1) The first year, such as figure 1 Shown: planting distance 1-1.2 meters, row spacing 2.5-3.5 meters; when the main vine grows to 70-80 cm high, tie it to the first iron wire on one side at 60 cm, so that the main vine and the ground are aligned Tilt at an angle of 60 degrees. During the growth process, leave the top buds, erase all the branches below the first wire, top off the main vine when it grows to about 160 cm, and keep the buds on the main vine to develop into new shoots. Leave 1 fruiting branch every 15 cm or so; form the first "arm" (main vine);

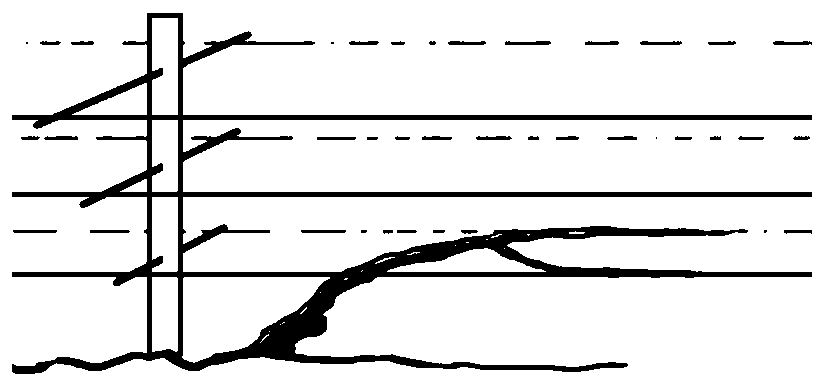

[0028] At the same time, if figure 2 As shown, at the position near the junction of the horizontal main vine and the first iron wire, pick a strong new shoot, tie it horizontally on the corresponding first iron wire on the other side, pick the heart when it grows to 100 cm, and keep this horizontal shoot. Buds on tied shoots, allowing them to develop into shoots, leaving 1 fruiting branch every 15 cm or so; for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com