Gas velocity adjustable solid-liquid reactive gas generator and method thereof

A technology for reacting gas and generating device, which is applied in the field of solid-liquid reacting gas generating devices, can solve the problems of large consumption of reagents, large reaction liquid, difficult reaction to complete, etc., achieves convenient control of reaction progress, and saves liquid reagents and reactions. Long stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

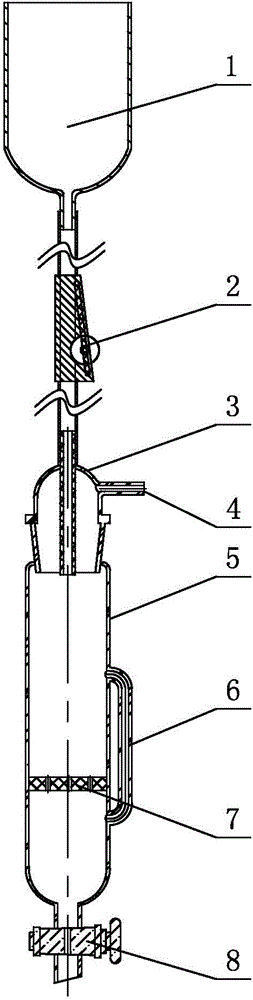

[0023] see figure 1 , the gas velocity-adjustable solid-liquid reaction gas generating device of the present embodiment is controlled by a liquid feeder 1, a liquid feed regulating valve 2, a reactor 5, a top cover 3, a sieve plate 7, a pressure balance pipe 6, and a liquid outlet The valve 8 and the air guide tube 4 are connected.

[0024] The reactor 5 of this embodiment is a glass tube with an open top and a liquid outlet in the center of the bottom. Its pipe diameter is 30.0 mm and its height is 200.0 mm. A glass top cover 3 is installed on the top opening of the reactor 5. There is a liquid inlet at the center of the glass top cover 3, and a gas outlet is provided on one side of the liquid inlet, and an air guide tube 4 is installed on the gas outlet, so that the generated gas can be exported and stored in a gas storage container. A liquid inlet pipe extending into the reactor 5 is installed on the liquid inlet, and a liquid addition regulating valve 2 is installed on th...

Embodiment 2

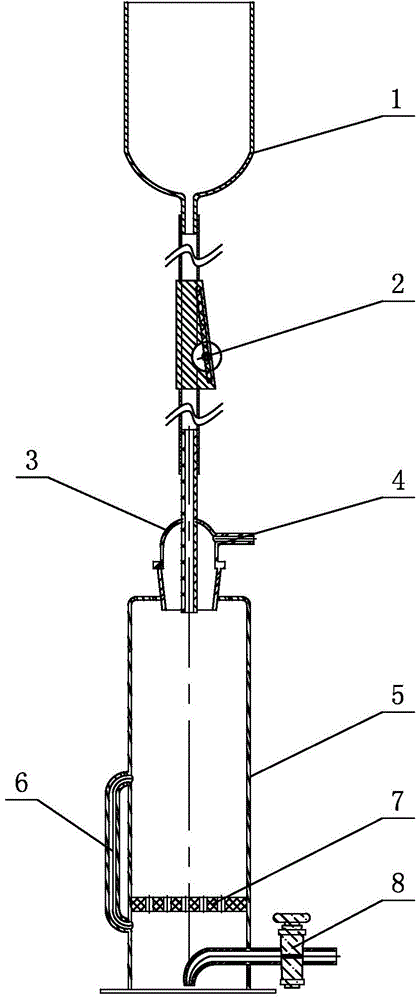

[0031] In the gas-generating device for solid-liquid reaction with adjustable gas velocity in this embodiment, the reactor 5 adopts a glass cup structure, see figure 2 When in use, it can be placed on the experimental platform. A glass sieve plate 7 is installed at the height of 3 / 5 of the inner chamber of the reactor 5 from top to bottom, and the inner chamber of the reactor 5 is divided into a reaction chamber and a waste chamber up and down. The liquid chamber has a liquid outlet on the bottom side wall of the waste liquid chamber, and a liquid outlet control valve 8 is installed on the liquid outlet for controlling the discharge of waste liquid.

[0032] Other components and their connections are the same as those in Embodiment 1.

[0033]The method for producing gas with this device is the same as in Example 1.

Embodiment 3

[0035] In the gas-generating device for solid-liquid reaction with adjustable gas velocity in this embodiment, the liquid inlet is opened on the side wall above the solid reactant in the reaction chamber, and a liquid guide is connected to the liquid inlet. One end extends inward to the center axis of the reaction chamber, and the other end extends to the outside of the reactor 5, and communicates with the liquid addition regulating valve 2 installed at the outlet of the liquid feeder 1 through a conduit. In order to ensure that the added liquid is evenly distributed in the reactor 5, An ordinary liquid distributor is installed at the end of the catheter. A ceramic sieve plate 7 is installed at a height of 1 / 2 from top to bottom in the reactor 5. The aperture of the sieve plate 7 is 3.0 mm to ensure that the waste liquid after reaction can flow smoothly from the reaction chamber to the waste liquid chamber.

[0036] Other components and their connections are the same as in Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com