Spraying pressure control system

A pressure control and voltage technology, applied in the direction of spraying devices, can solve the problems of difficult control of paint flow and low spraying efficiency, and achieve the effects of reducing paint waste, improving spraying efficiency, and stable and reliable hardware work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

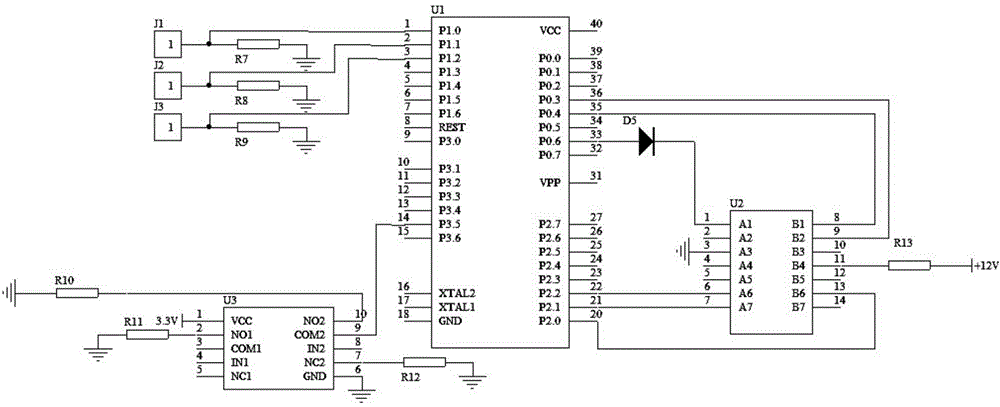

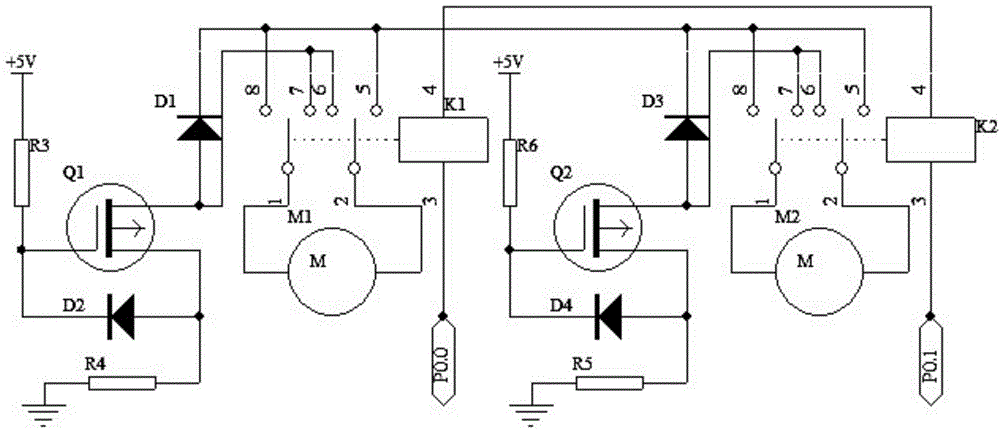

[0017] This embodiment includes: main control circuit ( figure 1 ), the sensor circuit ( figure 1 ),Drive circuit( figure 2 ).

[0018] figure 1 Among them, the main control circuit includes a chip U1, a chip U2, a diode D5, and a resistor R13. The pin 20 of the chip U1 is connected to the pin 13 of the chip U2, its pin 21 is connected to the pin 7 of the chip U2, and its pin 22 is connected to the chip Pin 6 of U2, pin 33 is connected to the anode of diode D5, pin 35 is connected to pin 8 of chip U2, pin 36 is connected to pin 9 of chip U2, pin 1 of chip U2 is connected to the anode of diode D5 The cathode, its pin 3 is grounded, its pin 11 is connected to one end of the resistor R13, and the other end of the resistor R13 is connected to the voltage +12V.

[0019] figure 1 Among them, the sensor circuit includes sensor J1, sensor J2, sensor J3, resistor R7, resistor R8, resistor R9, resistor R10, resistor R11, resistor R12, chip U3, and sensor J1 is connected to pin 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com