Method for improving coiling temperature control accuracy under laminar cooling model

A technology of temperature control and layer enhancement, applied in the direction of temperature control, etc., can solve the problems of reducing the coiling temperature control accuracy, unable to meet the needs of the production line, etc., and achieve the effect of improving the calculation accuracy of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

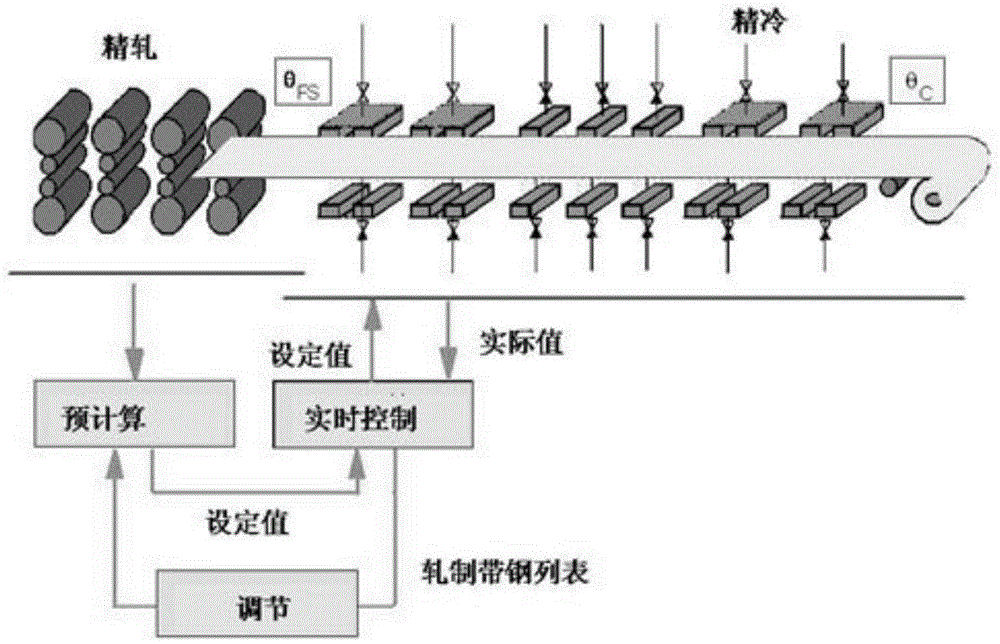

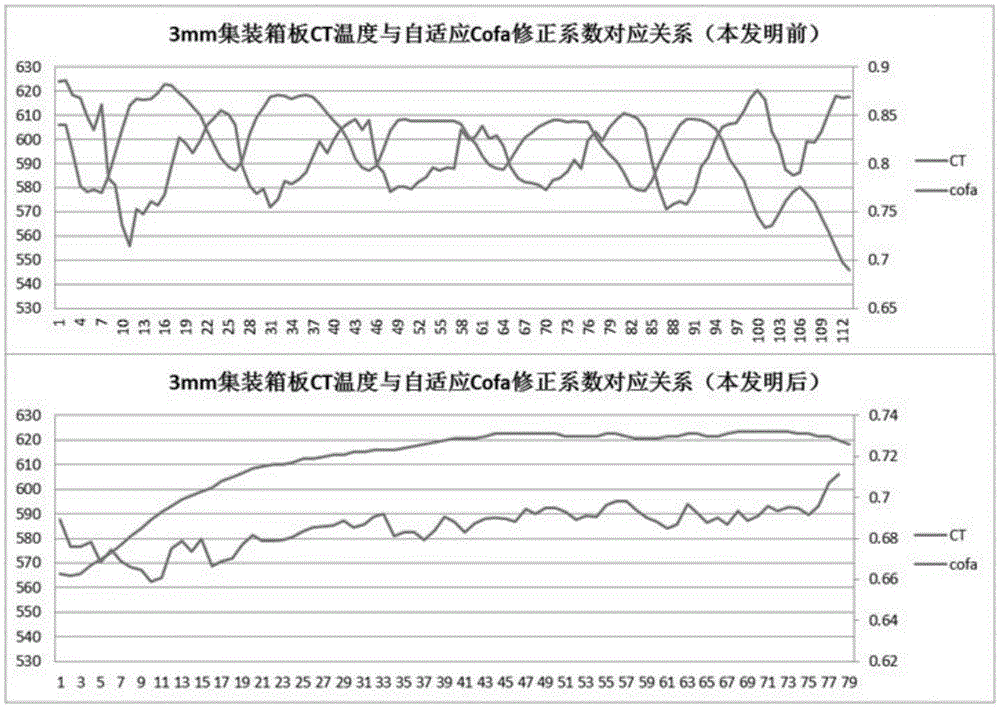

[0021] The embodiment of the present application provides a method for improving the coiling temperature control accuracy under the layer cooling model, which solves the problem that different steel specifications use the same parameter configuration in the prior art, but the same set of parameter configuration cannot meet the needs of the production line, resulting in coiling Take the problem of reduced temperature control accuracy; at the same time, solve the problem that there is no human intervention window under the model, resulting in abnormalities in external factors such as on-site process conditions, inaccurate model calculations, and on-site personnel being helpless.

[0022] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

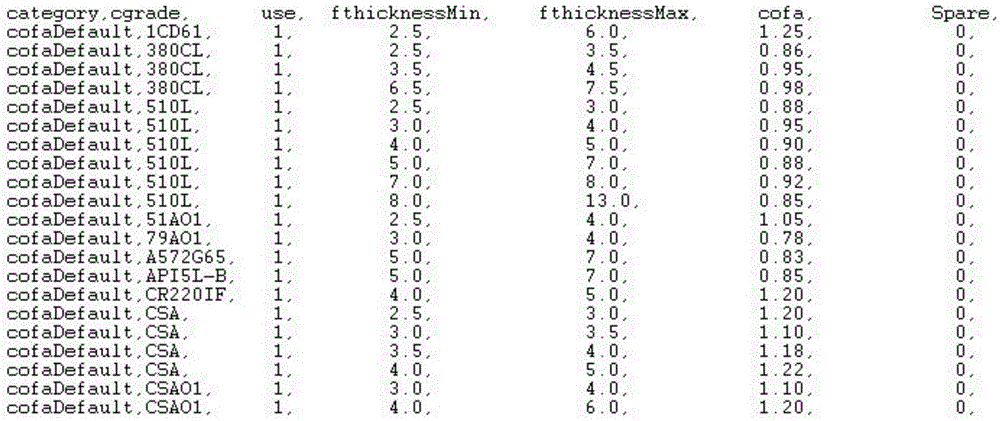

[0023] A method to improve the coiling temperature control accuracy under the interlayer cooling model. In the pre-calculation stage, when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com