Heat transfer printing coding machine electric control system based on STM32 single chip microcomputer development

A thermal transfer, single chip technology, applied in general control systems, control/regulation systems, computer control and other directions, can solve the problems of slow thermal transfer printers, high costs, and inability to modify printing information at will, to improve Production efficiency, low cost, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

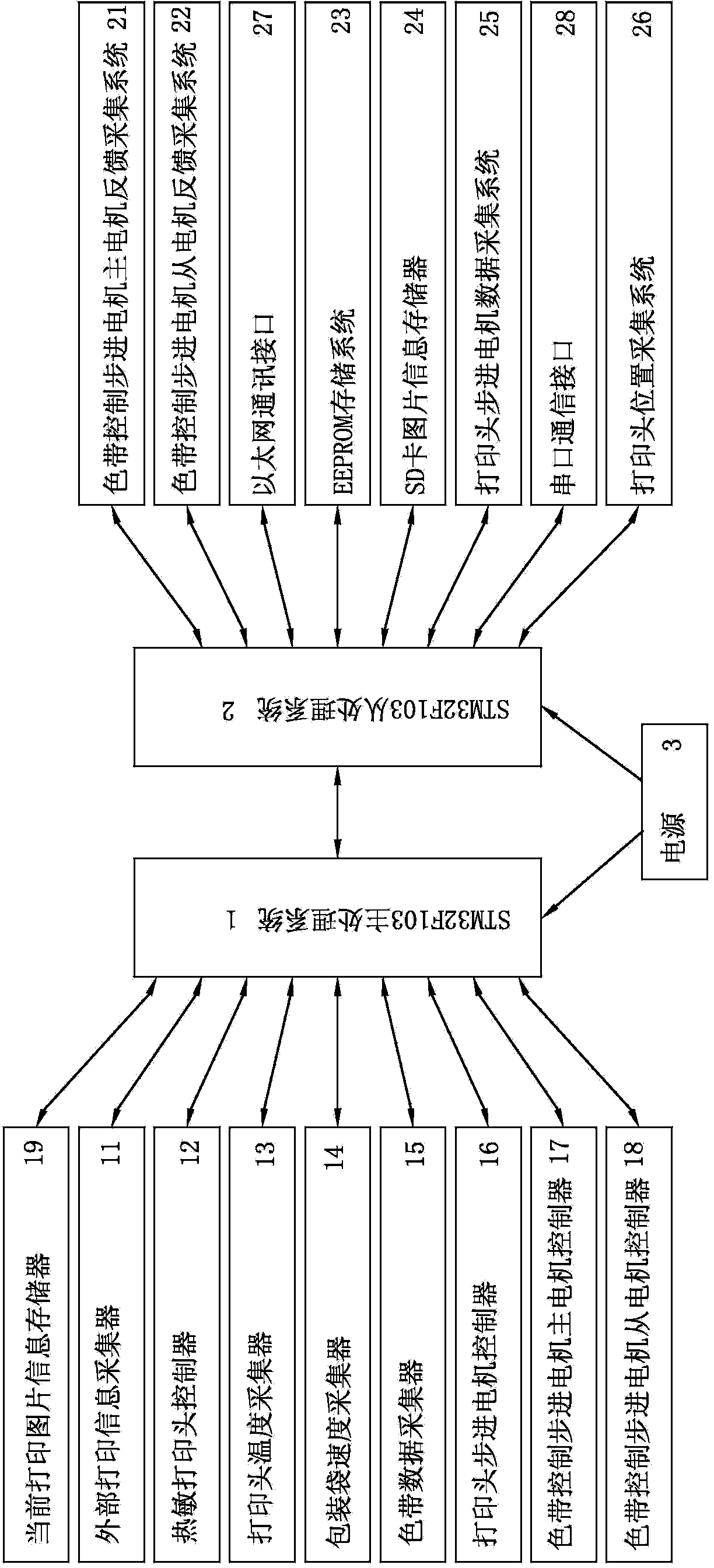

[0018] refer to figure 1 The thermal transfer printer electric control system developed based on STM32 single-chip microcomputer shown includes power supply, control equipment and STM32F103 processor system, and the information data output / input port of the STM32F103 processor system is connected to the control through data lines The information data input / output port of the device is characterized in that: the STM32F103 processor system includes a STM32F103 main processor system 1 and an STM32F103 slave processor system 2, and the STM32F103 main processor system 1 is used to control the operation of the device control operating system; STM32F103 slave processor system 2 is a processing system for the collection, storage and monitoring of control equipment operation information data, and the STM32F103 main processor system 1 establishes two-way data transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com