O-ring assembly method

An assembly method and sealing ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low pass rate, low efficiency, and difficulty in manual assembly of O-ring seals, and achieve assembly efficiency and pass rate High, no damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

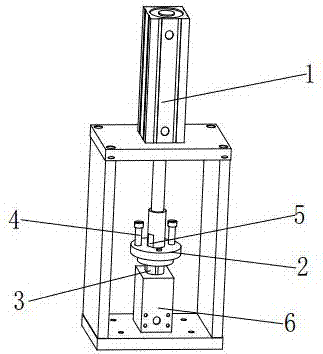

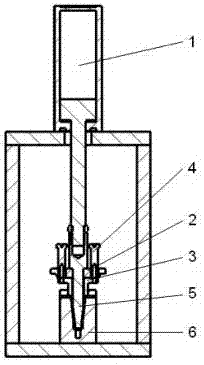

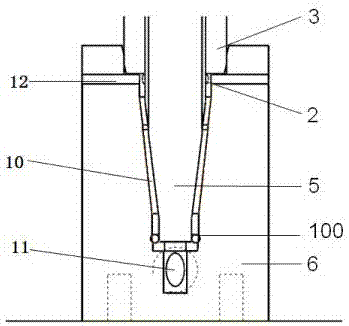

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] like Figure 1-4 Shown, the assembly method of O-ring of the present invention comprises the steps:

[0023] (1) Ring release: place the O-shaped sealing ring on the support ring cone, either manually or by an automatic feeding device for the front sealing ring.

[0024] (2) Ring preparation: The ring cylinder drives the ring cone to go deep into the ring channel in the ring cone cavity, and the ring channel, air inlet and exhaust channel are arranged in the ring cone cavity ;

[0025] (3) Support ring: Tightly cover the ring transfer guide sleeve 2 outside the support ring cone 5, the air inlet 11 starts to intake air, and under the action of the air flow, the O-shaped sealing ring 100 moves upward along the support ring cone 5 to the transfer ring On the guide sleeve 2, the stripping sleeve 3 is set outside the ring transfer guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com