Thick plate printing device

A printing and platen technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of low printing efficiency and inability to print thick, etc., and achieve the effects of flexible use, improved efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

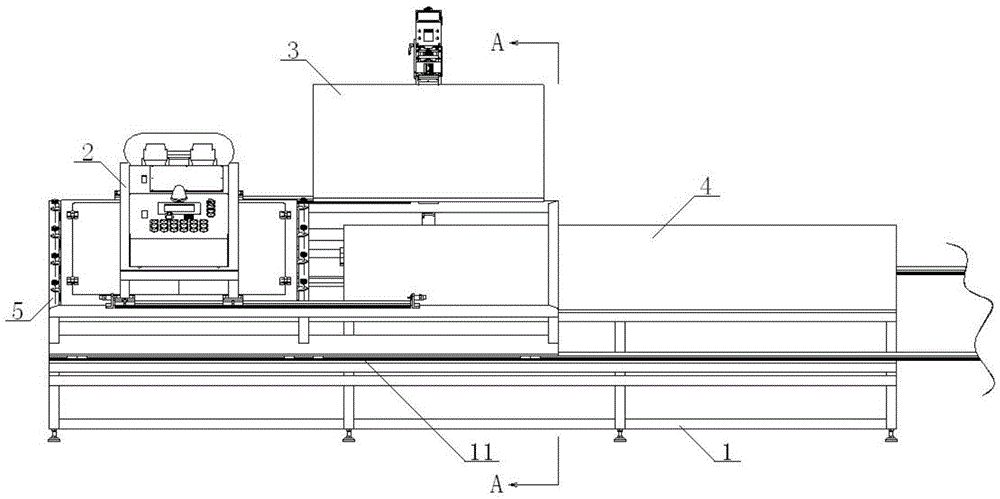

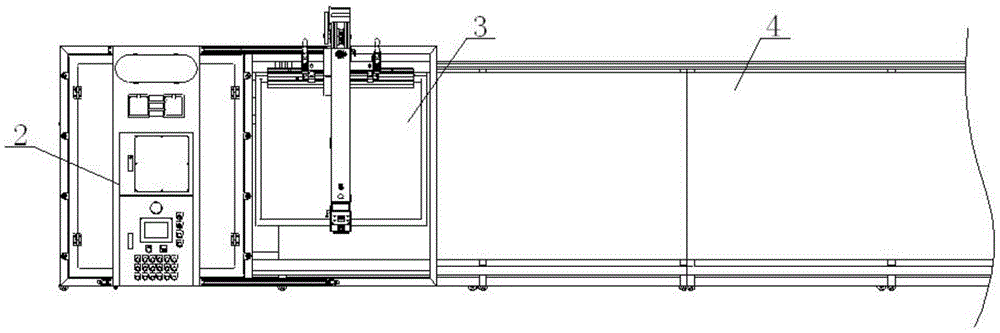

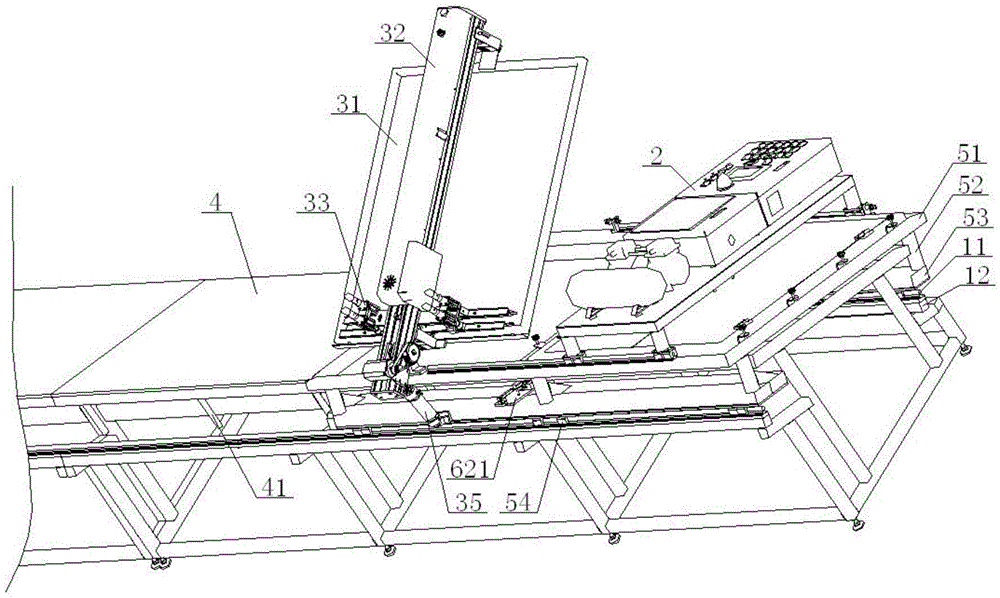

[0046] see Figure 1 to Figure 5 , a thick plate printing device, comprising a frame 1, a heating and drying mechanism 2, and a printing mechanism 3, the front and rear sides of the frame 1 are provided with linear guide rails 11, and the frame 1 is provided with a Platen 4, the position on the left side of platen 4 on the platen 4 is provided with a support mechanism 5, the upper end of the support mechanism 5 is provided with a heating and drying mechanism 2, a printing mechanism 3 in sequence from left to right, and the lower end of the support mechanism 5 is connected to the The linear guide rail 11 is matched, and the printing mechanism 3 includes a screen frame 31 and a printing arm 32. The front part of the printing arm 32 is connected with the front end of the support frame 51 through the printing arm support 34, and the front end of the printing arm 32 is connected by a telescopic cylinder 35. It is connected with the front end of the support plate 53, the lower end o...

Embodiment 2

[0048] Basic content is the same as embodiment 1, the difference is:

[0049] see Figure 1 to Figure 5 , the frame 1 includes a bottom beam 13, a first front vertical beam 14, a first rear vertical beam 15, and a second Front vertical beam 16, the second rear vertical beam 17, the height of the second rear vertical beam 17 is greater than the height of the second front vertical beam 16, the lower end of the second front vertical beam 16 and the second rear vertical beam 17 are all connected with the bottom The upper end surface of the crossbeam 13 is vertically connected, the upper end of the second front vertical beam 16 is connected with the lower end surface of the front part of the platform 4, and the upper end of the second rear vertical beam 17 is connected with the lower end surface of the rear part of the platform 4; The top of the front vertical beam 14 is provided with a front cross beam 110, the front cross beam 110 is perpendicular to the bottom cross beam 13, an...

Embodiment 3

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] see Figure 1 to Figure 5, the support mechanism 5 includes a support frame 51, a support plate 53, and a slider 54. The support frame 51 is located above the platen 4 and the support frame 51 is parallel to the platen 4. The lower end surface of the support frame 51 passes through the pillar 52 It is connected with the upper end surface of the support plate 53, and the lower end surface of the support plate 53 is connected with the upper end surface of the slider 54. The upper end faces are connected;

[0053] The lower end of the front portion of the platen 4 is located at the rear side of the linear guide rail 11 and is provided with a positioning pin 41. The positioning pin 41 cooperates with the positioning mechanism 6, and the positioning mechanism 6 is arranged on the lower end surface of the support plate 53; the support plate 53 includes a front support plate 531 and a rear support plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com