Suspension structure below train of motor train unit

An EMU and wheel bearing technology, applied in suspension, elastic suspension, vehicle parts, etc., can solve the problems of easy rolling of vehicles, deformation of shock absorbers, oil leakage, and difficulty in nodding, and achieve reasonable structural design, Durable and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

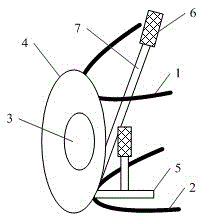

[0021] In Embodiment 1, a suspension structure under the EMU is provided, please refer to figure 1 , the structure includes:

[0022] Upper wishbone 1, lower wishbone 2, wheel bearing 3, first damping strut, second damping strut, disk 4, cross bar 5, wherein, described wheel bearing is installed on the side of described disk, so The remaining parts of the vehicle suspension structure are installed on the other side of the disc; the upper yoke and the lower yoke are U-shaped; the upper yoke is connected to the upper end of the disc, and the lower yoke is connected to the upper end of the disc. The yoke is connected to the lower end of the disc; one end of the cross bar is connected to the lower end of the disc; both the first damping strut and the second damping strut are composed of a coil spring 6 and a shock absorber 7, The coil spring is sleeved on the outer surface of the shock absorber, one end of the first shock absorber strut is connected to the bottom end of the disc,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com