A construction vehicle tire cleaning device

A technology for cleaning devices and tires, which is applied to vehicle exterior cleaning devices, vehicle cleaning, and vehicle cleaning equipment, etc., can solve the problems of inconvenience, time-consuming, and labor-intensive construction site management personnel, and achieve the effect of saving manpower, easy operation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

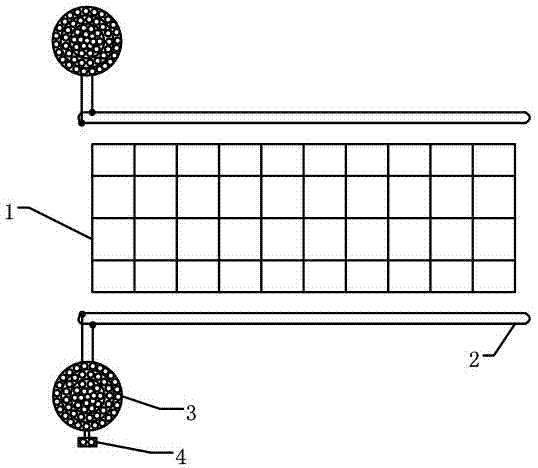

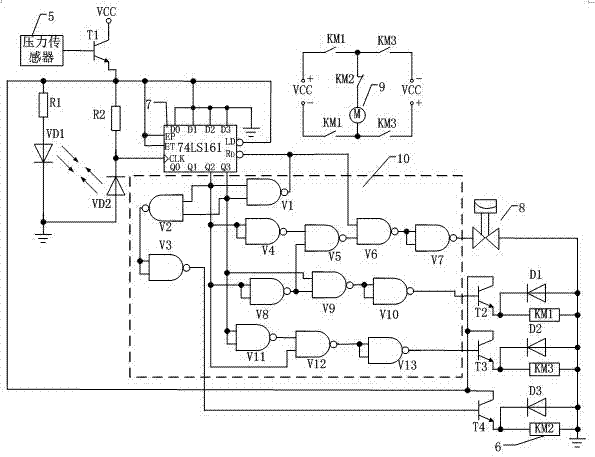

[0019] Embodiment 1: as Figure 1-2 As shown, a construction vehicle tire cleaning device includes a water leakage frame 1, a guide rail 2, a sprinkler 3, a self-reflective infrared tube module 4, and a control circuit; the guide rail 2 is installed on both sides of the water leakage frame 1, and the guide rail 2, the sprinkler 3 is installed, and the self-reflective infrared pipe module 4 is installed on the top of any one of the sprinklers 3; the control circuit includes a pressure sensor 5, a relay 6, a 74LS161 counter 7, a solenoid valve 8, a DC motor 9, The combined logic gate circuit 10 controls the working state of the triode T1 according to the output signal of the pressure sensor 5, thereby controlling the power supply of the subsequent circuit; the self-reflective infrared tube module 4 outputs a control signal to the 74LS161 counter 7, and the output signal of the 74LS161 counter 7 passes through The combined logic gate circuit 10 controls the action of the solenoid...

Embodiment 2

[0020] Embodiment 2: as Figure 1-2 As shown, a construction vehicle tire cleaning device includes a water leakage frame 1, a guide rail 2, a sprinkler 3, a self-reflective infrared tube module 4, and a control circuit; the guide rail 2 is installed on both sides of the water leakage frame 1, and the guide rail 2, the sprinkler 3 is installed, and the self-reflective infrared pipe module 4 is installed on the top of any one of the sprinklers 3;

[0021]The control circuit includes a pressure sensor 5, a relay 6, a 74LS161 counter 7, a solenoid valve 8, a DC motor 9, and a combined logic gate circuit 10, and controls the working state of the triode T1 according to the output signal of the pressure sensor 5, thereby controlling the power supply of the subsequent circuit Situation; self-reflection infrared tube module 4 outputs control signal to 74LS161 counter 7, 74LS161 counter 7 output signal controls solenoid valve 8, relay KM1, relay KM3, relay KM2 action through combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com