Lifting appliance for transferring heavy forklift portal frame

A technology of forklift mast and spreader, which is applied in the field of spreader for heavy-duty forklift mast transfer, which can solve the problems of low work efficiency and poor safety, achieve high work efficiency, convenient hoisting, and reduce secondary repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

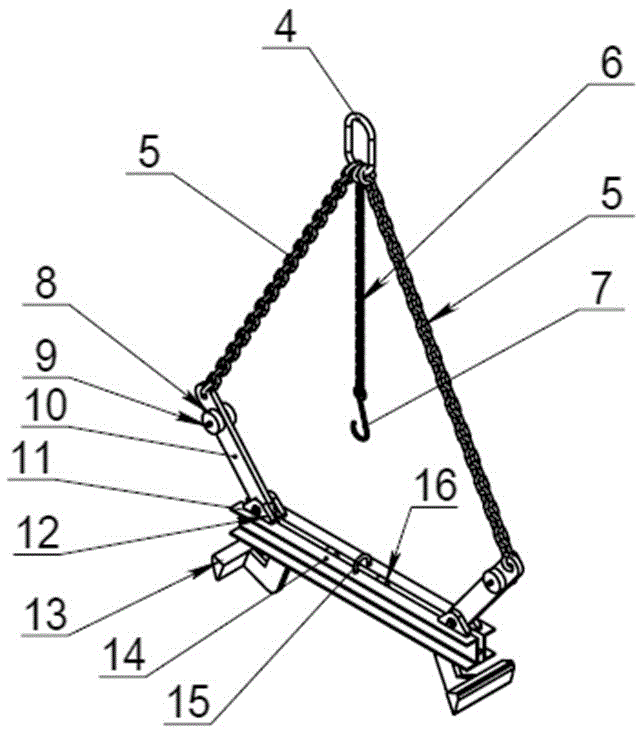

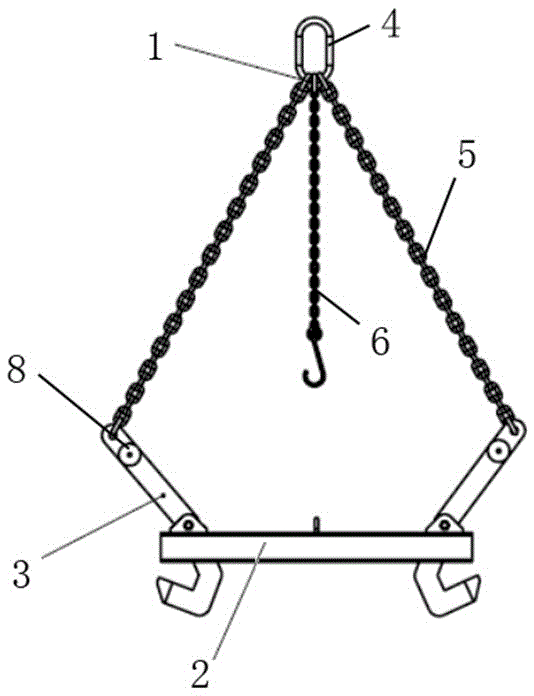

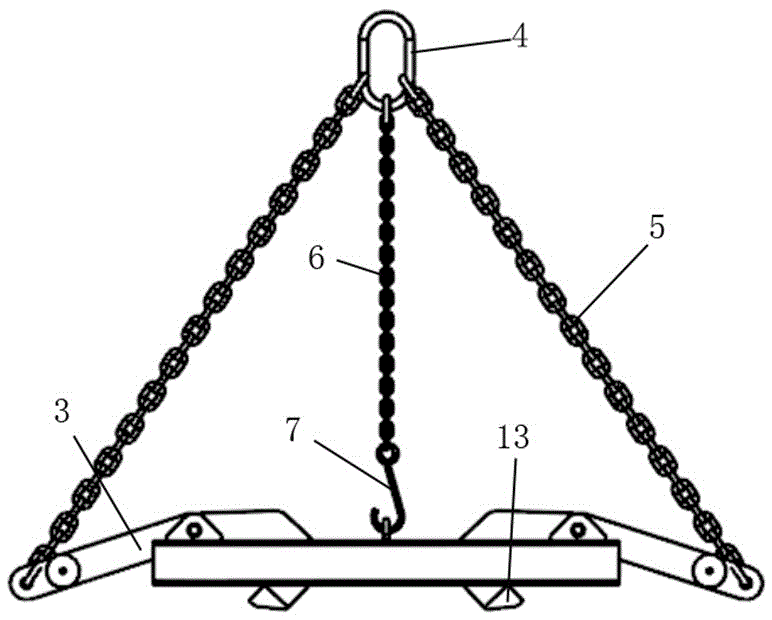

[0023] see figure 1 , figure 2 , the spreader used for the transfer of heavy-duty forklift masts, including hitch components and lifting chain components;

[0024] The hitch assembly includes a crossbeam 2 and two hooks 3, and the hooks 3 are located at both ends of the crossbeam 2; Connection, the middle part of two channel steels is provided with auxiliary articulated ring 15, and the middle gap of two channel steels forms rotating groove 14, and the two ends of every channel steels are all provided with support plate 12; The upper end of described suspension hook 3 is At the handle end, the handle end is provided with a counterweight 8 through a positioning pin 9, the lower end of the hook 3 is a hook end, and a foot plate 13 is horizontally arranged on the end of the hook end. The surface is covered with a layer of rubber pad;

[0025] The handle ends of the two hooks 3 are movably connected to the two ends of the rotating groove 14 through the pin shaft 11 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com