Horizontal force self-balancing type splayed heavy type upper air support system and installation method thereof

A self-balancing, support system technology, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of unfavorable vertical concentration of the main beam of No. 0 block, high pouring support, and large amount of materials, so as to eliminate the disadvantages. Influence, wide application span, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

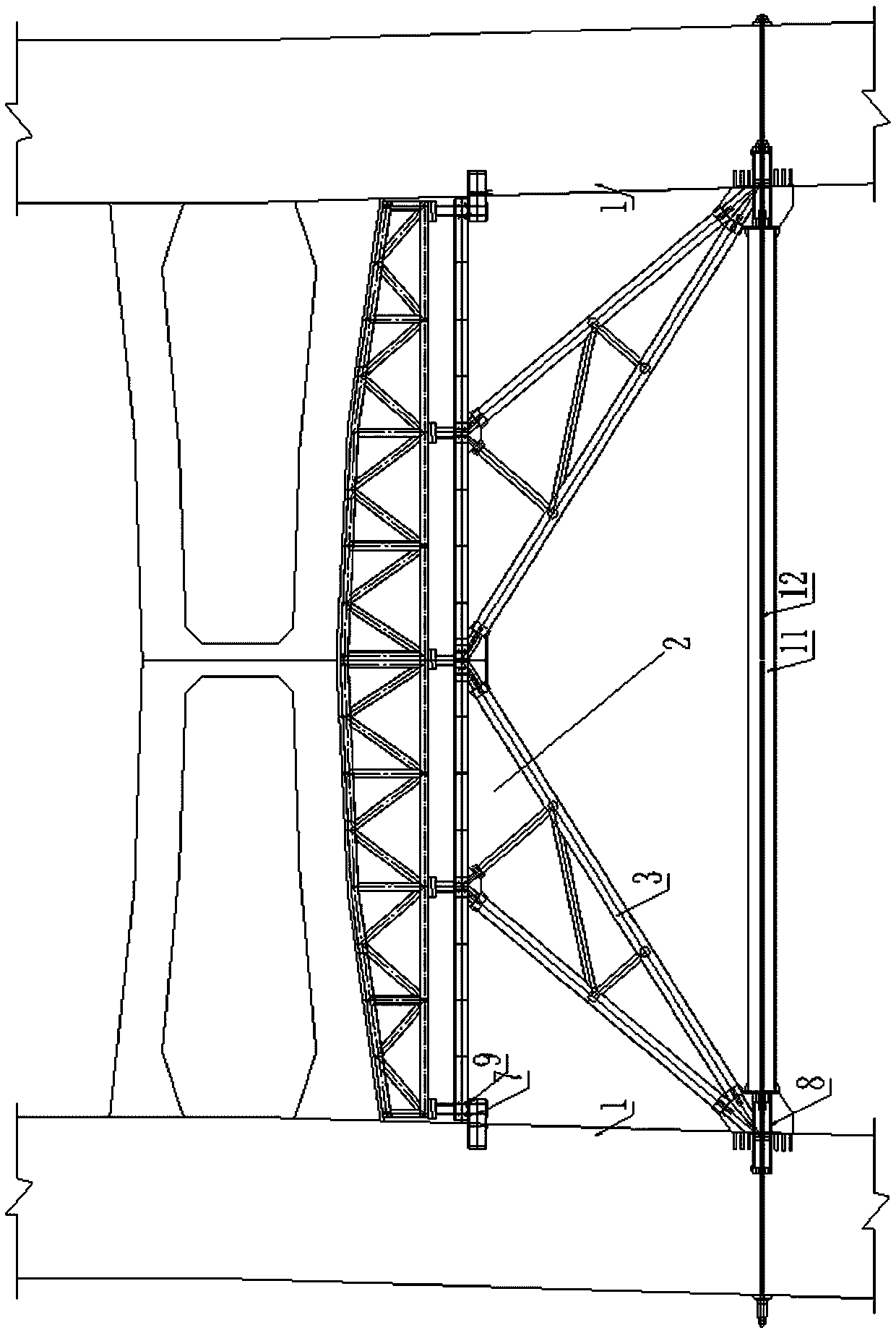

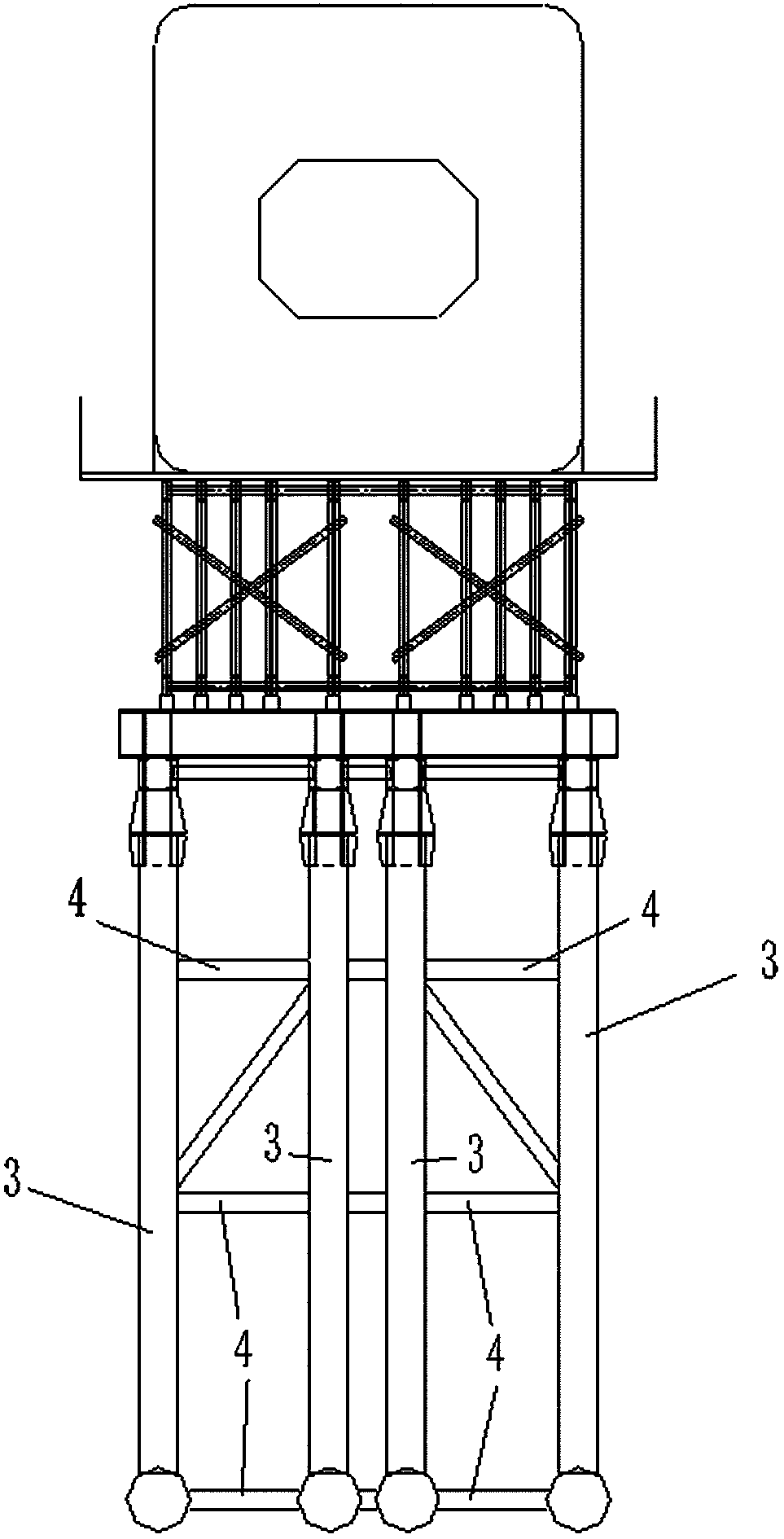

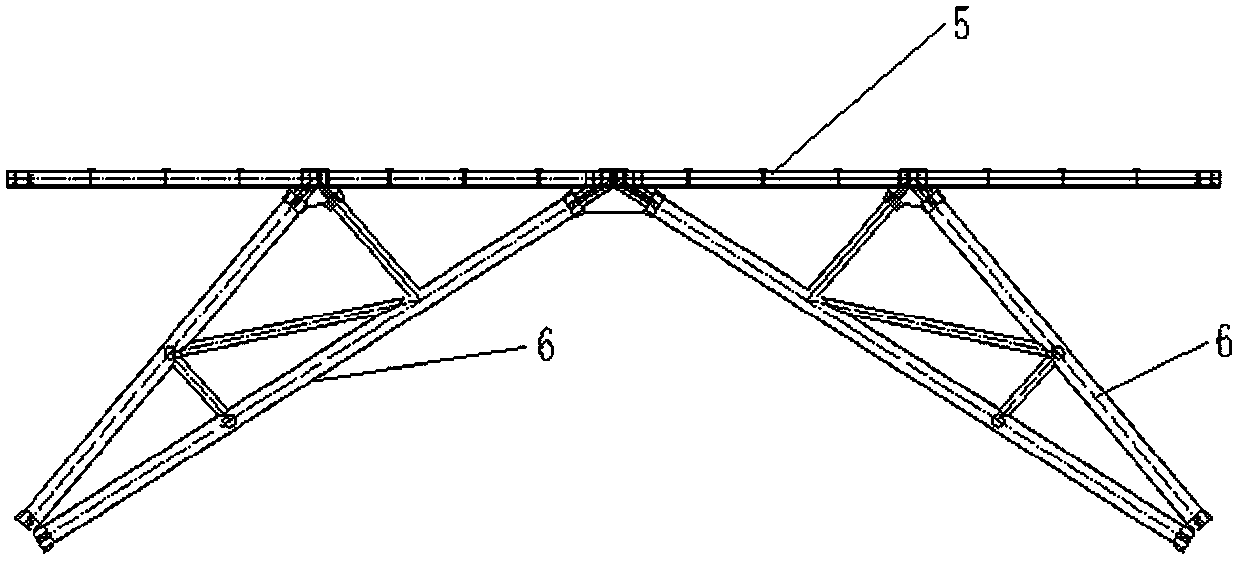

[0028] according to Figure 1-Figure 6 As shown, the horizontal force self-balancing type eight-shaped heavy-duty high-altitude support system of the present invention includes a number of force-bearing units 2 arranged at intervals between adjacent bridge tower columns 1, and each force-bearing unit 2 is connected by a connecting rod 4 connection, each stress unit 2 includes the upper steel corbel 7 and the lower steel corbel 8 respectively pre-buried on the tower columns 1 of the bridge body on both sides, and the two ends are respectively placed on the upper and lower steel corbels 7 and 8 Figure 8 rigid frame 3 on the top.

[0029] The figure-eight rigid frame 3 is welded by the steel girder 5 and the triangular diagonal bracing truss 6. The two sides of the figure-eight rigid frame 3 have an upper fulcrum and a lower fulcrum respectively, and the upper fulcrum and the lower fulcrum are connected to the upper steel bull On leg 7 and lower steel corbel 8.

[0030] One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com