Public toilet closestool cleaning machine

A technology for washing machines and toilets, which is applied to sanitary equipment, water supply devices, buildings and other directions for toilets, can solve the problems of large physical injury, high cost, and unsatisfactory cleaning and disinfection effects for workers, and achieves automatic and efficient cleaning process. Easy to operate and avoid the effect of dirty water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

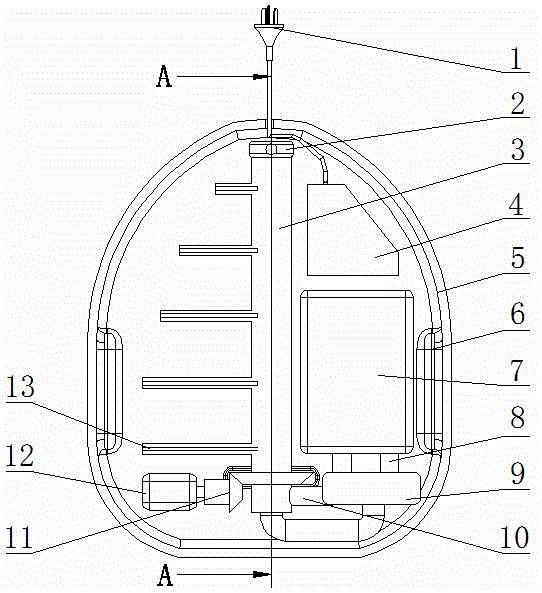

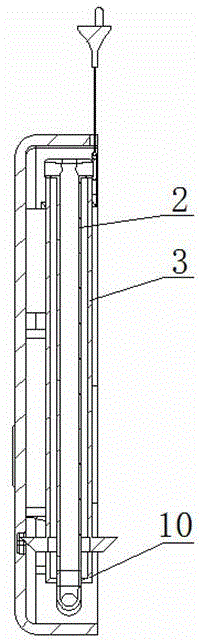

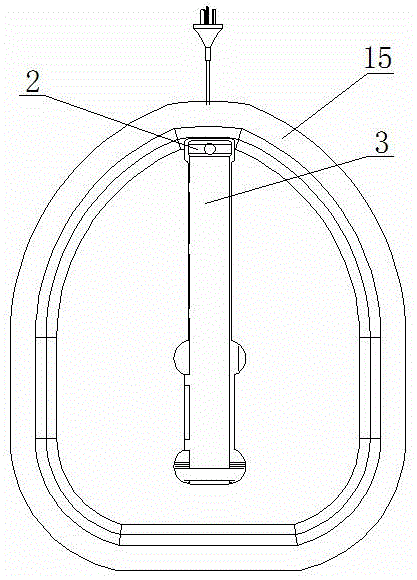

Embodiment 1

[0027] Embodiment 1: as Figure 1-5 Shown, this public toilet toilet cleaning machine comprises cleaning nozzle 13, rotating cylinder 3, circulating pump 9, upper casing 5, lower casing 15, electric control device 4 and water tank heating device 7. The cleaning spray head 13 is connected to the rotating cylinder 3 through waterproof colloid, and the rotating cylinder 3 and the motor 12 are driven and connected through the bevel gear 11 . The upper casing 5 is provided with an electric control device 4 and a water tank heating device 7 . The electric control device 4 is connected with the motor 12 to control the speed and flow. The circulation pump 9 is connected to the water tank heating device 7 through a bendable pipe 8 , and the circulation pump 9 is connected to the rotary cylinder 3 through a turnable water outlet 10 . The power plug 1 is connected with the electric control device 4 to provide electric energy for the machine.

Embodiment 2

[0028] Embodiment 2: This public toilet toilet cleaning machine includes a cleaning nozzle 13, a rotating cylinder 3, a circulating pump 9, an upper casing 5, a lower casing 15, an electric control device 4 and a water tank heating device 7. The cleaning spray head 13 is connected to the rotating cylinder 3 through waterproof colloid, and the rotating cylinder 3 and the motor 12 are driven and connected through the bevel gear 11 . The upper casing 5 is provided with an electric control device 4 and a water tank heating device 7 . The electric control device 4 is connected with the motor 12 to control the speed and flow. The circulation pump 9 is connected to the water tank heating device 7 through a bendable pipe 8 , and the circulation pump 9 is connected to the rotary cylinder 3 through a turnable water outlet 10 . The power plug 1 is connected with the electric control device 4 to provide electric energy for the machine.

[0029] The inside of the rotating cylinder 3 is c...

Embodiment 3

[0030] Embodiment 3: This public toilet toilet cleaning machine includes a cleaning nozzle 13, a rotating cylinder 3, a circulating pump 9, an upper casing 5, a lower casing 15, an electric control device 4 and a water tank heating device 7. The cleaning spray head 13 is connected to the rotating cylinder 3 through waterproof colloid, and the rotating cylinder 3 and the motor 12 are driven and connected through the bevel gear 11 . The upper casing 5 is provided with an electric control device 4 and a water tank heating device 7 . The electric control device 4 is connected with the motor 12 to control the speed and flow. The circulation pump 9 is connected to the water tank heating device 7 through a bendable pipe 8 , and the circulation pump 9 is connected to the rotary cylinder 3 through a turnable water outlet 10 . The power plug 1 is connected with the electric control device 4 to provide electric energy for the machine.

[0031] The nozzles of the cleaning spray head 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com