Modular integrated building system

A building system and modular technology, applied in the direction of architecture, building components, building structures, etc., can solve problems such as difficult remedial measures, disengagement of wall panel laps, and cracking of formwork, so as to avoid wall damage and ensure rigidity and the firmness of the connection, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

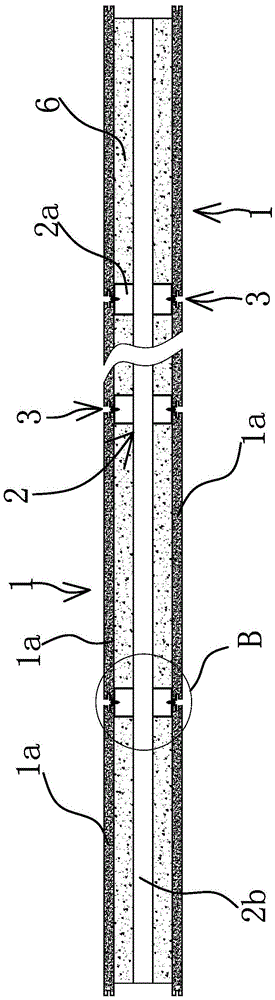

[0052] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

[0053] like Figure 11 As shown, each wallboard panel unit 1a has lapping arms 1a3 and snapping arms 1a4 respectively located on both sides, and the fastener 3 includes a fastening screw 3a, and the fastening screw 3a passes through the wallboard panel unit 1a. The snap-fitting arm 1a3 and the lapping arm 1a4 of the adjacent wallboard panel unit 1a are connected to the support 3 . Certainly, the overlapping arm 1a3 and the buckling arm 1a4 may be L-shaped extension arms, or other feasible ways. Of course, in the actual production process, in order to prevent the two wallboard panel units 1a from being too close together, causing the wall filler 6 to have no expansion space and damage the wallboard panel 1, a gap between two adjacent wallboard panel units 1a Generally, there will be a certain gap, and when the final completion, in order not to affect...

Embodiment 3

[0055] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

[0056] like Figure 12 As shown, the fastener 3 includes a fastening screw 3a, and two adjacent wallboard panel units 1a are connected to the same support 3 through at least one fastening screw 3a. The fastening screws 3a can be used directly on each wallboard panel unit 1a to realize the connection, which can make the processing of the wallboard panel unit 1a easier.

Embodiment 4

[0058] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

[0059] like Figure 13 As shown, the connecting pipe is a square pipe, and the square pipe can also achieve the purpose of smooth flow diversion, as long as one of the edges of the square pipe is set downward, that is, the sharper side of the pipe is set downward, and there is an inclination The diversion auxiliary surface is sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com