A simulation test platform and test method for rotary spray curing and sealing holes

A simulation test and hole sealing technology, which is used in earth-moving drilling, sealing/isolation, wellbore/well components, etc. It can solve the problems of borehole sealing experiment without gas drainage, and the test cannot be completed with high quality and quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

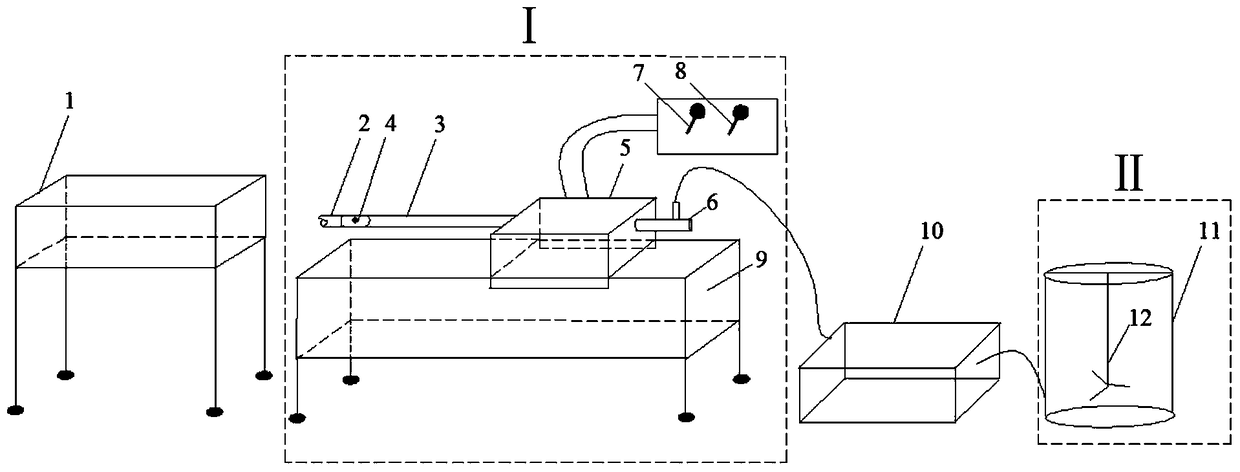

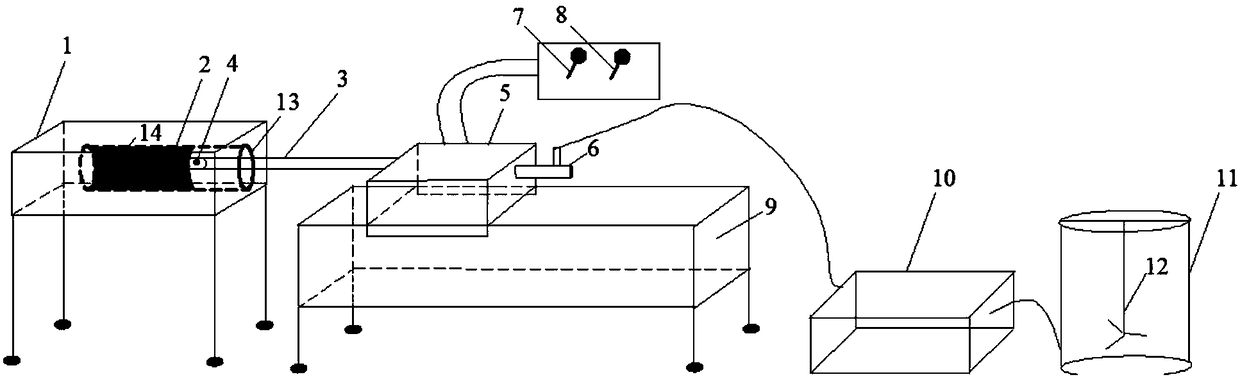

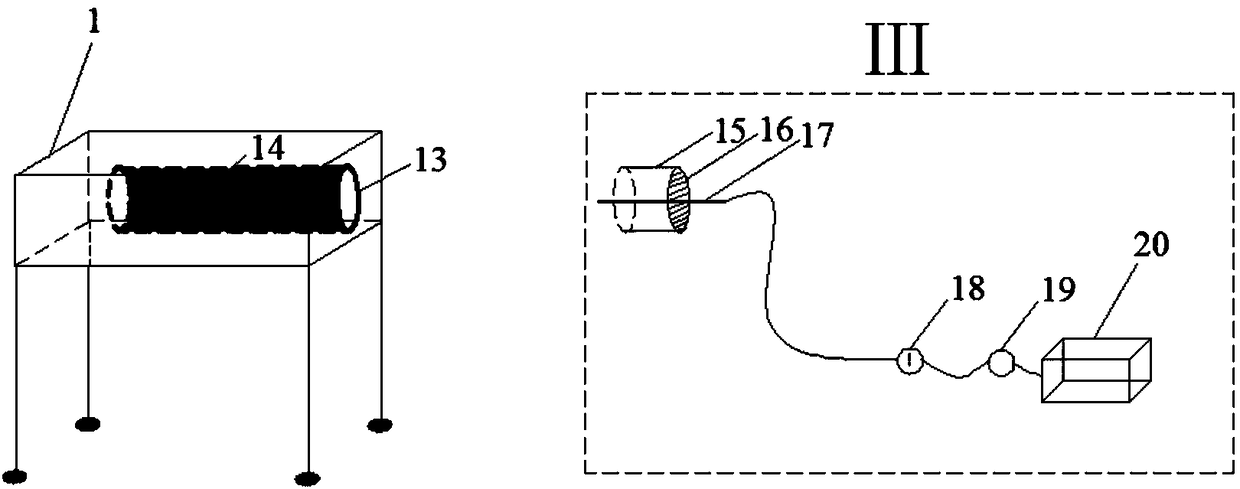

[0038] Embodiment 1: according to the appended figure 1 After the simulation platform is built as shown, open the cover plate of the coal / rock mass fixed platform 1, mix the screened coal (rock) powder, water and other ingredients evenly, pour them into the coal / rock mass fixed platform 1, and close the cover and tighten the nuts between the plates to solidify the test block; when the test block is solidified and formed, open the left baffle of the coal / rock mass fixing table 1, and use the rotary jet drilling machine I to construct a drill in the test block. Hole 13, during the retraction process of drill pipe 3, the nozzle 4 on the drill pipe 3 spins out the sealing slurry, which is evenly sprayed on the inner wall of the drill hole 13 to form a sealing layer 14, and the slurry penetrates into the surrounding cracks / pores and solidified, isolated the connection between the borehole 13 and the surrounding cracks / pores; according to the attached image 3As shown, use sealant ...

Embodiment 2

[0039] Embodiment 2: according to the appended figure 1 After the simulation platform is built as shown, open the cover plate of the coal / rock mass fixed platform 1, mix the screened coal (rock) powder, water and other ingredients evenly, pour them into the coal / rock mass fixed platform 1, and close the cover plate and tighten the nuts between the plates to make the test block solidify and form; when the test block is solidified and formed, open the cover plate of the coal / rock mass fixing platform 1 again, and cover the steel pressure plate with the same size as the cover plate on the The upper surface of the test block, and the entire coal / rock mass fixing platform is placed under the pressure testing machine to simulate the hole formation and sealing conditions under different stress (corresponding to the burial depth of coal rock), and the subsequent operation steps are the same as in the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com