Free piston linear electric generator

A linear generator and piston type technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as difficult control, complex structure, and unstable compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

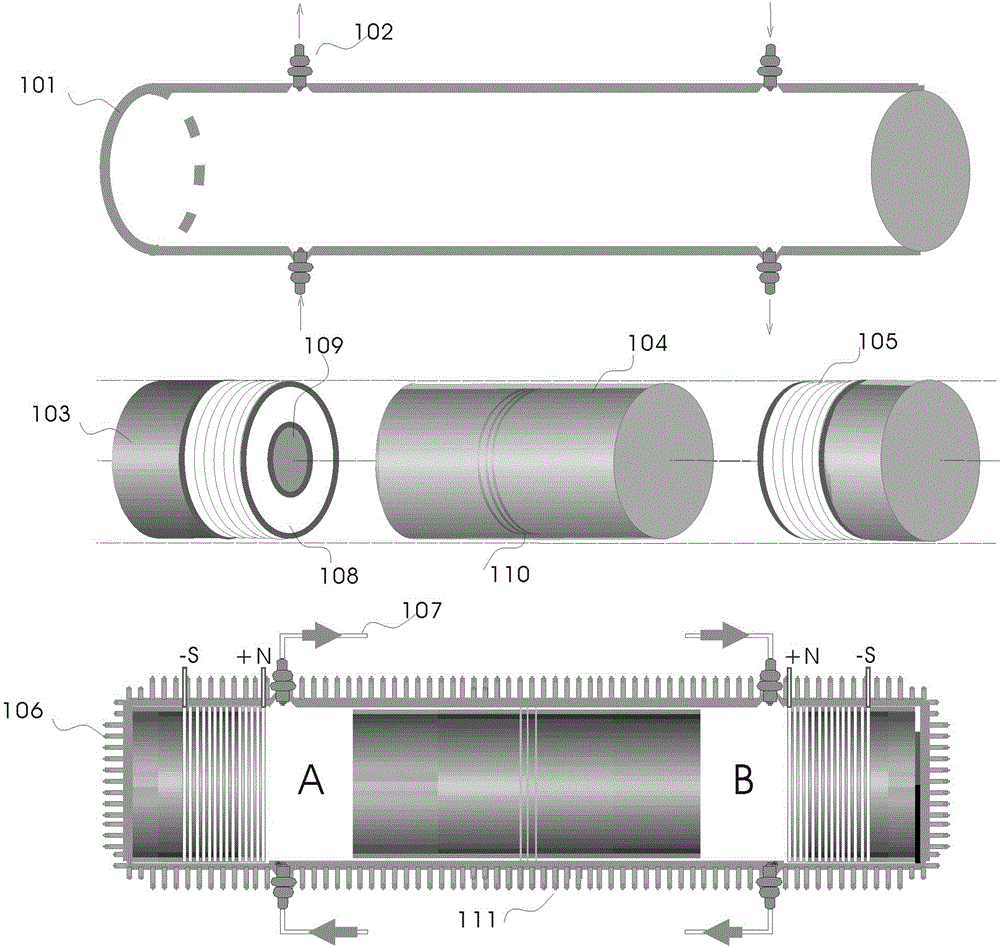

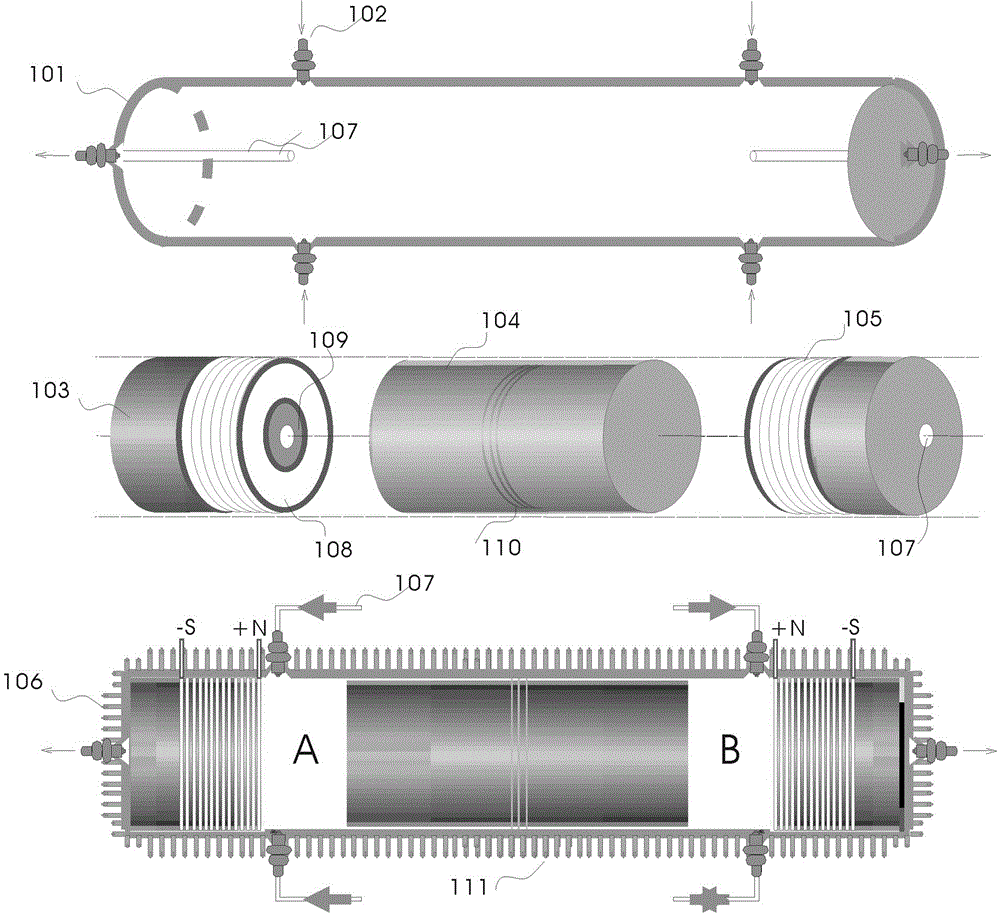

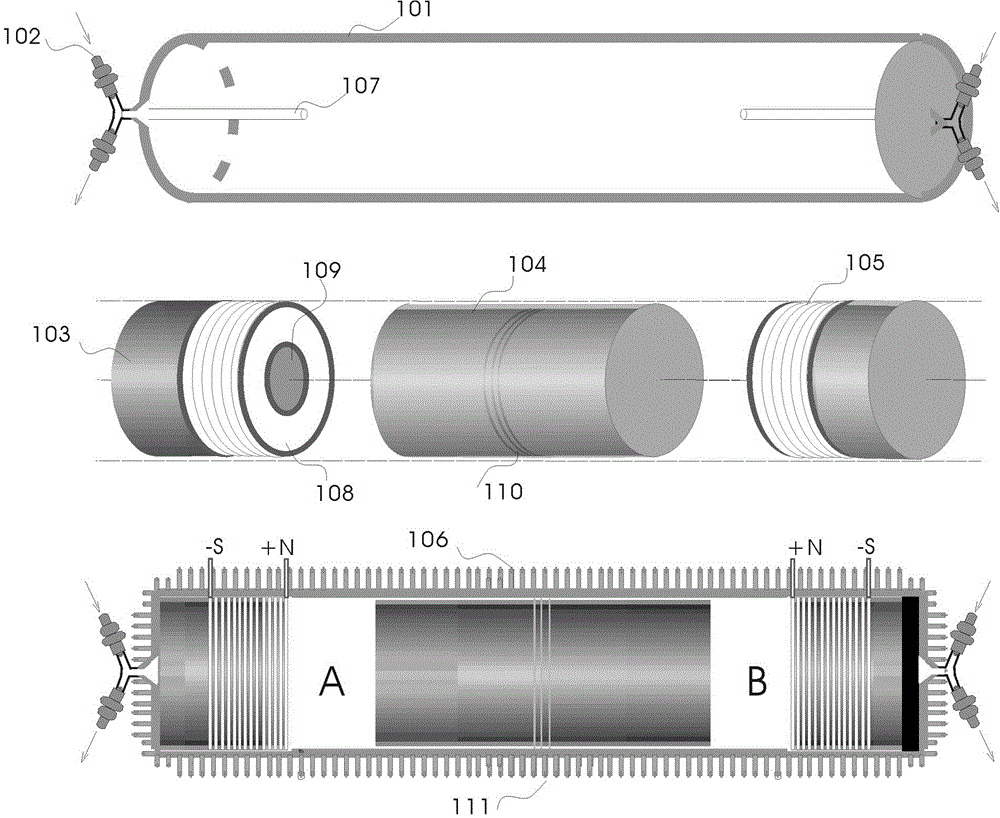

[0041] A free-piston linear generator, firstly, the operator starts the electronic control unit, and the compressed gas tank sends compressed gas to the segment A cylinder through the intake pipe 107, and the segment A cylinder takes in air—the permanent magnet piston 104 expands the stroke, and the permanent magnet piston 104 expands the stroke. The magnet piston 104 moves toward the segmented cylinder B, and at the same time, the segmented cylinder B exhausts—the compression stroke. When the permanent magnet piston 104 moves to the top dead center, the electric permanent magnet 103 and the permanent magnet piston 104 have the same magnetic pole to generate repulsive force and enter Under the combined force of compressed air pressure (intake time, commanded by the electronic control unit of the sensor), the permanent magnet piston 104 is forced to move to the segmented cylinder A, and the segmented cylinder A exhausts——the compression stroke of the permanent magnet piston 104, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com