Low-noise deep groove ball bearing

A deep groove ball bearing, low noise technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve problems such as cage abnormal vibration, cage noise, cage interference, etc., to avoid abnormal vibration and reduce noise , Improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

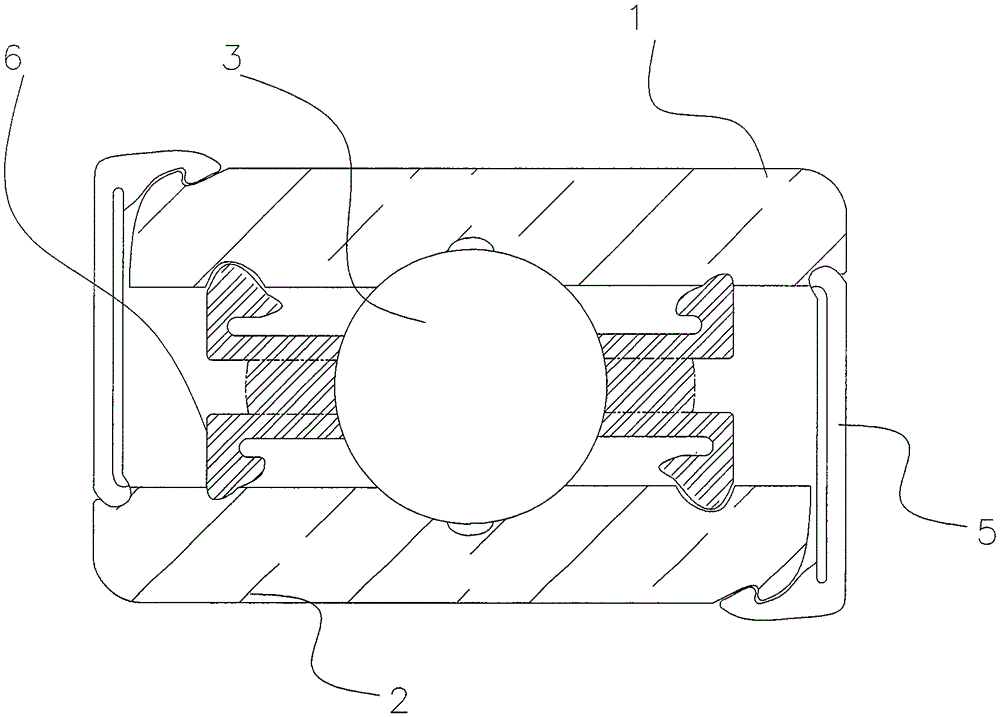

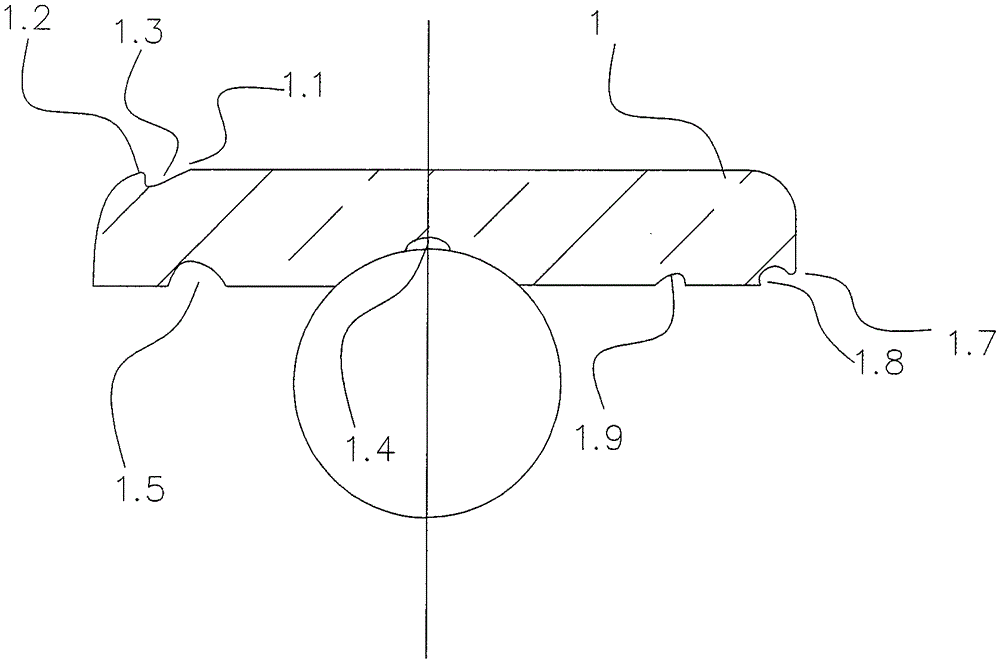

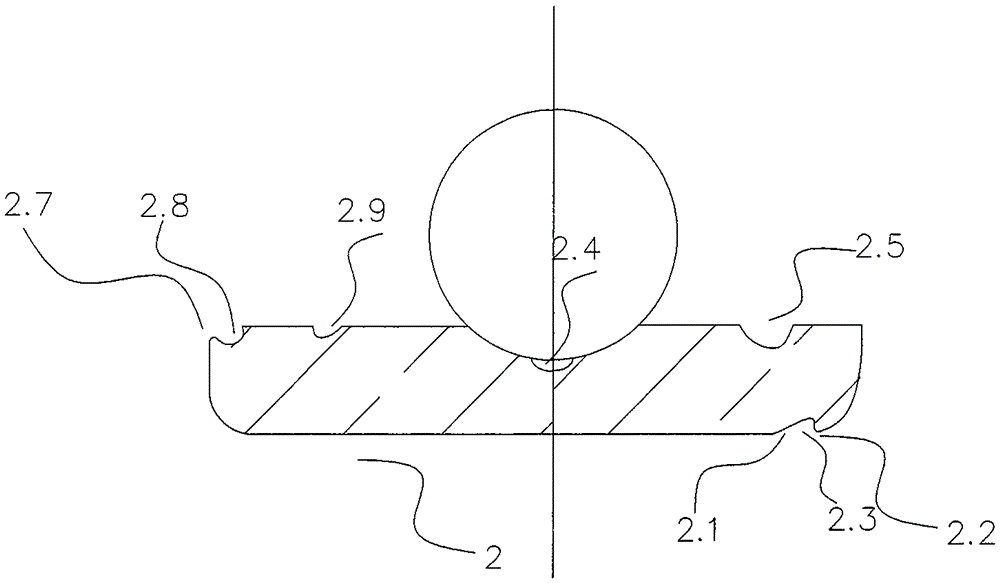

[0034] The invention provides a low-noise deep groove ball bearing, such as figure 1 As shown, it includes a bearing outer ring 1, and a bearing inner ring 2 coaxially arranged inside the bearing outer ring, and a plurality of bearing balls 3 are arranged between the bearing outer ring 1 and the bearing inner ring 2, the bearing The ball 3 can roll in the outer raceway of the inner surface of the bearing outer ring 1 and the outer raceway of the outer surface of the bearing inner ring 2 .

[0035] The inner cavity between the bearing outer ring 1 and the bearing inner ring 2 of the deep groove ball bearing is sealed by two annular sealing rings 5 arranged axially opposite to each other, and the inner cavity between the bearing outer ring 1 and the bearing inner ring 2 The cavity is filled with bearing lubricant.

[0036] Such as Figure 4 As shown, the annular section of the sealing ring 5 has a multi-layer structure, including the outermost radial sealing edge 5.4, which ...

Embodiment 2

[0045] Further preferably, the cavity between the bearing outer ring 1 and the bearing inner ring 2 of the deep groove ball bearing is distributed with a bearing cage 6 that is interlocked by two parts, so that a plurality of bearing balls 3 are arranged in the circumferential direction to Evenly spaced and maintained.

[0046] Such as Figure 5 As shown, the half of the bearing cage 6 on the side of the bearing ball 3 includes a partially spherical cavity 6.7, and the two half sides are formed as a spherical cavity that contains and holds the bearing ball. In the axial direction between 2, the two sides of the spherical cavity form two annular grooves 6.2 and 6.4. The openings of the two grooves are opened to the bearing ball raceway and the openings diverge. The two grooves can be symmetrical or asymmetrical. The annular groove can be used as an additional groove for storing lubricant. During the operation of the bearing, the lubricant is temporarily accumulated and prevent...

Embodiment 3

[0049] Further preferred, such as Image 6 As shown, the joint position of the bearing cage 6 between the bearing balls 3 is in the form of a fastening piece, preferably in the form of a tenon and a groove, so that the two halves of the bearing cage are fastened together without other connections Way.

[0050] Further preferred tenons and grooves are selected as a hollow frustoconical shape with a hole, and the hole communicates the bearing cage with the outer central annular spaces 6.5 and 6.6, so that the space between the cages is connected to the bearing outer ring and The spaces between the inner rings are in fluid communication.

[0051] The cage and the radial sealing edge can be made of plastic materials, such as polyamide 66 and polyhexamethylene amide. Such materials have good wear resistance under heavy loads, and have a small friction coefficient and good aging resistance. Of course, it can also be produced from conventional materials such as steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com