A new type of gas burner

A gas burner, a new type of technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems affecting the health of kitchen staff, insufficient mixing of fire outlets, unreasonable layout, etc., to improve efficiency, The structure is simple and compact, and the effect of reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

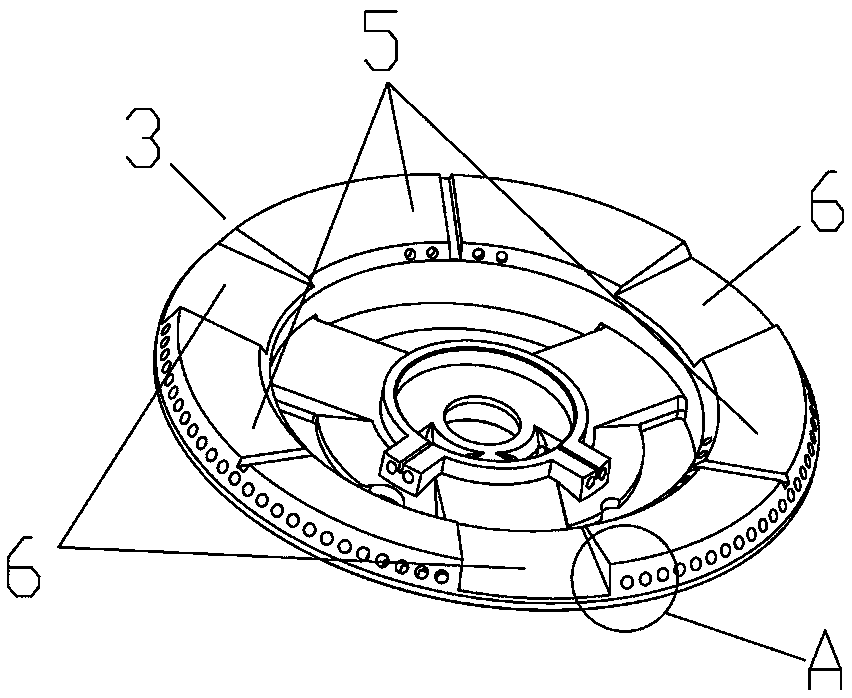

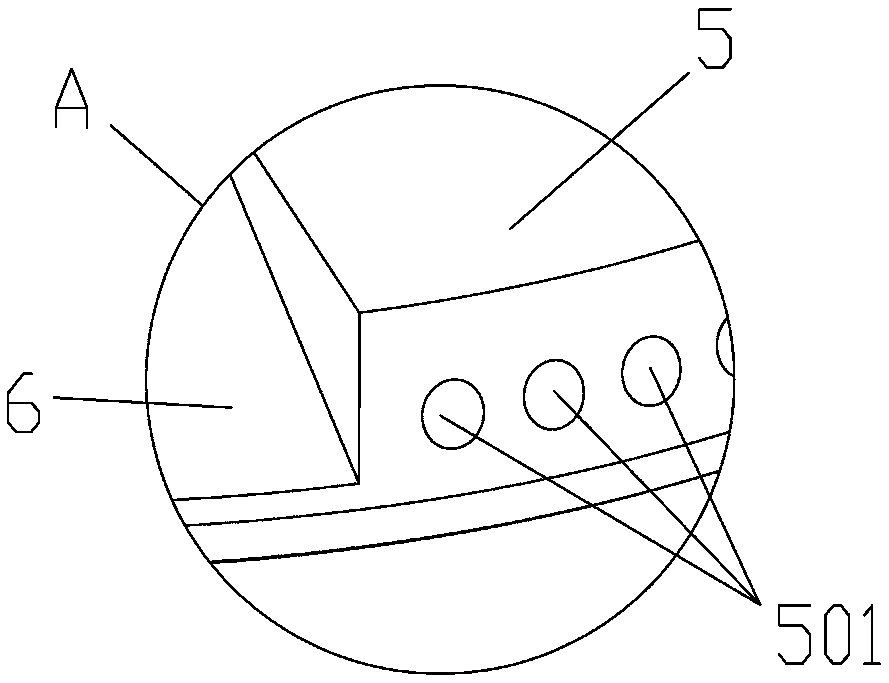

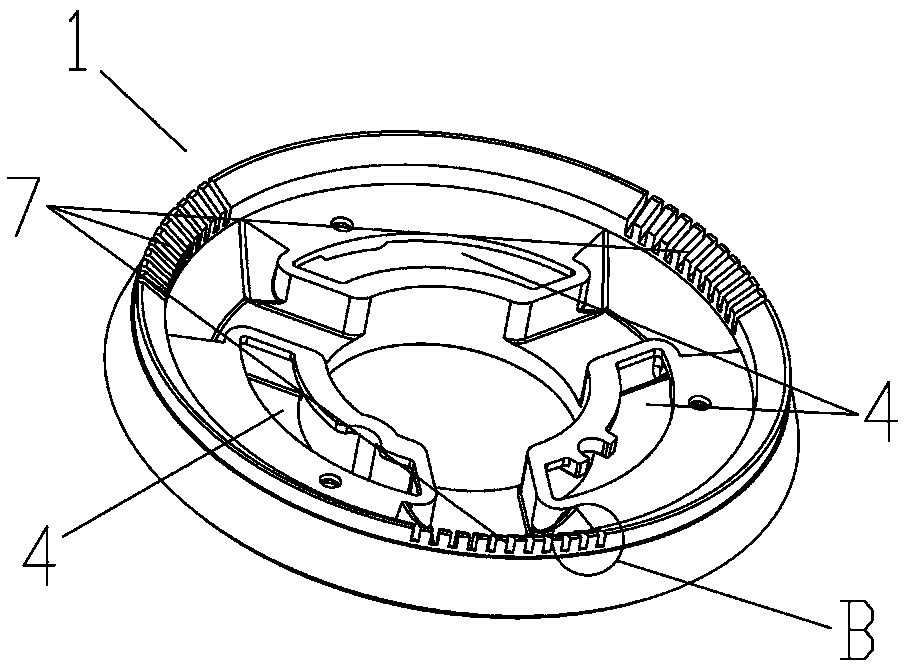

[0027] The first embodiment: as Figure 1 to Figure 8 As shown, a new type of gas burner includes a combustion seat 1, an inner ring fire distribution cover 2 and an outer ring fire distribution cover 3 are respectively installed on the combustion seat 1, the inner ring fire distribution cover 2 and the outer ring fire distribution cover 3 A plurality of air inlet passages 4 are provided on the combustion seat 1 between them, and it is characterized in that, the outer ring fire distribution cover 3 is provided with a multi-section upper fire distribution hole group 5 in the circumferential direction, each section of the upper layer fire distribution hole group 5 A plurality of upper-layer fire distribution holes 501 are provided, and the air entering the concave cavity 6 communicated with the air inlet channel 4 is formed between each section of the upper-layer fire distribution hole group 5, and a plurality of lower-layer fire distribution holes are arranged under the air ente...

no. 2 example

[0035] The second embodiment: as Figure 9 to Figure 10 As shown, compared with the first embodiment, the lower fire distribution hole group 7 is arranged on the combustion seat 1. In this embodiment, the lower fire distribution hole group 7 is arranged on the outer ring fire distribution cover 3, specifically: the air enters the concave Bosses 10 extend downwards from the edge of the outer ring fire distribution cover 3 below the chamber 6, and the corresponding combustion seat 1 is provided with a groove 11 that cooperates with the boss 10. The lower fire distribution hole group 7 is arranged on the boss 10. The lower fire distribution hole group 7 cooperates with the groove 11 to form a plurality of lower fire distribution holes 701. The upper fire distribution hole 501 and the lower fire distribution hole 701 are integrated on the outer ring fire distribution cover 3. The process is simple and convenient for forging. The beneficial effect of the first embodiment can be ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com