Projectile holder separating system based on momentum theorem

A separation system and momentum theorem technology, which is applied in the field of the bullet carrier separation system based on the momentum theorem, can solve the problem of disturbing the water surface splash shape and the shape of the cavitation, the shooting quality of the projectile entering the water image, and the bullet carrier having a great influence on the trajectory of the projectile body. and other problems, to achieve the effect of improving gas utilization efficiency, increasing air tightness, and improving emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

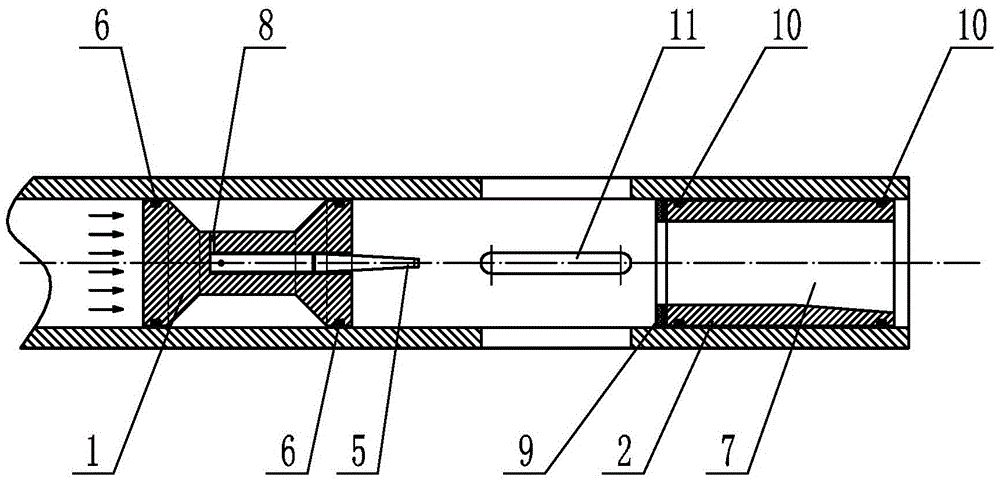

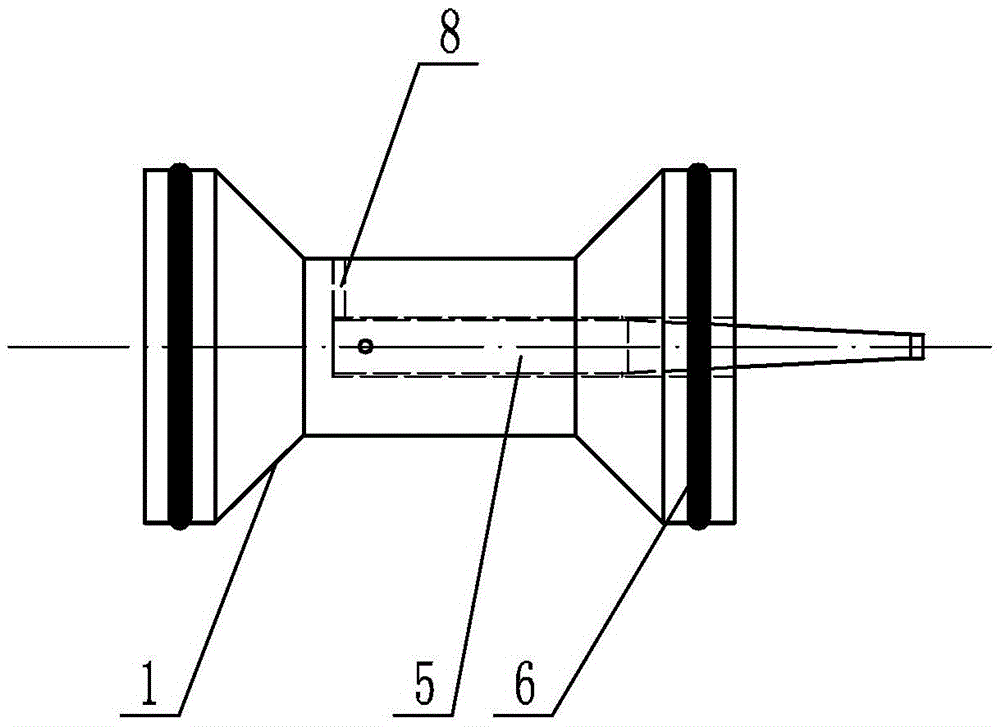

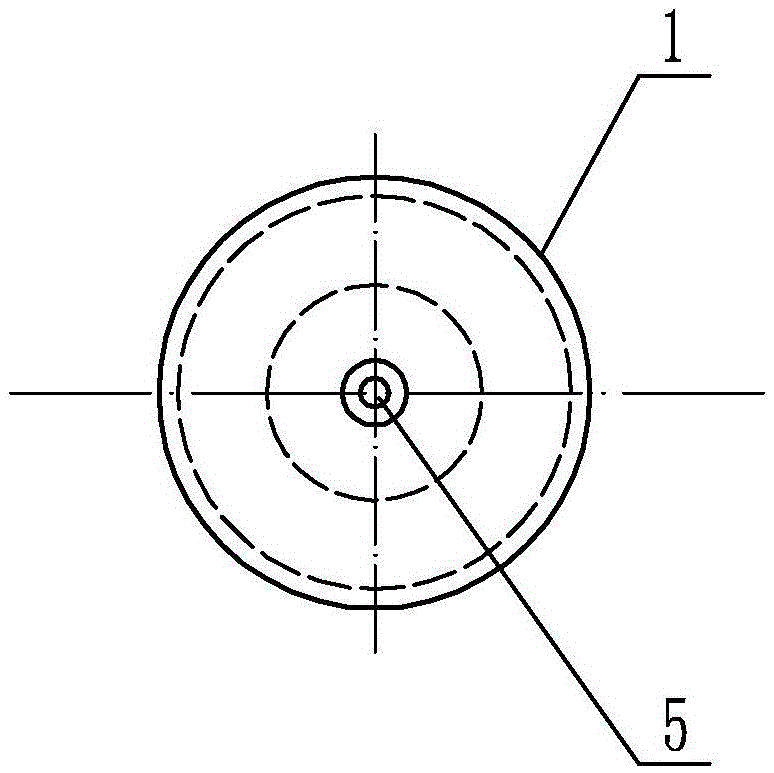

[0030] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Illustrate this embodiment, comprise accelerating bullet holder 1, stop bullet holder 2, recovery cover 3, gun barrel 4, projectile 5 and buffer gasket 9 in this embodiment, described acceleration bullet holder 1 and blocking bullet holder 2 are all provided with In the gun barrel 4, the accelerating bullet holder 1 is arranged away from the muzzle of the gun barrel 4, and the blocking bullet holder 2 is arranged near the muzzle of the gun barrel 4, and a buffer is arranged between the accelerating bullet holder 1 and the blocking bullet holder 2 Gasket 9, the buffer gasket 9 is closely attached to the blocking bullet holder 2, the acceleration bullet holder 1 is a revolving body, and the acceleration bullet holder 1 is processed with a projectile placement cavity, and the projectile 5 is arranged on The projectile is placed in the chamber an...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination figure 1 , figure 2 and image 3 This embodiment will be described. In this embodiment, the acceleration flip holder 1 is a spindle-shaped body of revolution. In this embodiment, the spindle-shaped structure provided on the acceleration spring rest 1 can effectively reduce its weight, and other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 Describe this embodiment, in this embodiment, the buffer gasket 9 is a gasket made of rubber, and the center of the buffer gasket 9 is processed with a through hole, and the through hole is coaxially arranged with the projectile passing hole 7 and connected. The setting of buffer spacer 9 is in order to buffer the rigid collision between two bullet holders, avoid bullet holder damage. Cushioning pads made of rubber provide better cushioning. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com