Linear and angular displacement sensor measurement system and method

A technology of angular displacement and measurement system, which is applied in the field of measurement, can solve problems such as increased cost and occupied space, complicated steps, and difficult detection, and achieves the effects of saving occupied space, high resolution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

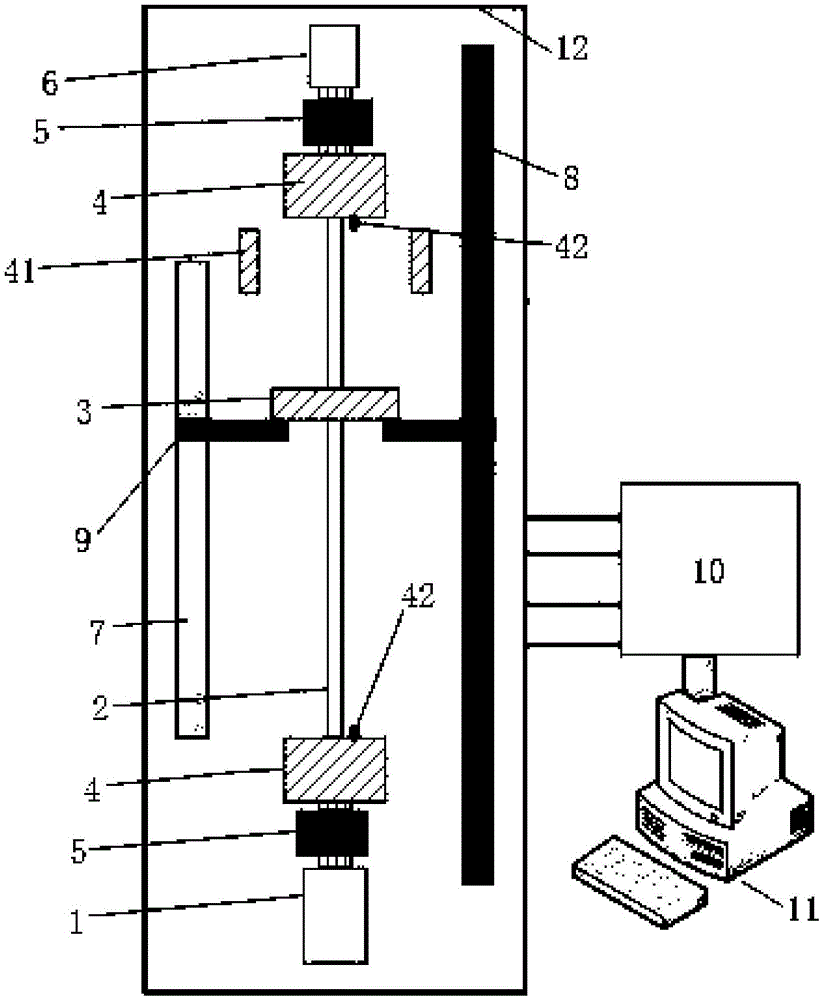

[0027] Such as figure 1 As shown, a linear and angular displacement sensor measurement system includes a servo motor 1, a ball screw 2, a nut slider 3, a screw fixing seat 4, a coupling 5, an angular displacement sensor 6, a standard grating ruler 7, and a Measuring linear displacement sensor 8;

[0028] The ball screw 2 passes through the nut slider 3, and the screw fixing seats 4 are respectively installed at both ends, and the servo motor 1 and the angular displacement sensor 6 are respectively installed on the shaft coupling 5 On the screw fixing seat 4, the rotation of the ball screw 2 drives the angular displacement sensor 6 to move synchronously; the standard grating ruler 7 and the measured linear displacement sensor 8 are respectively connected by the magnetic force of the magnet 9 The nut slider 3 is driven.

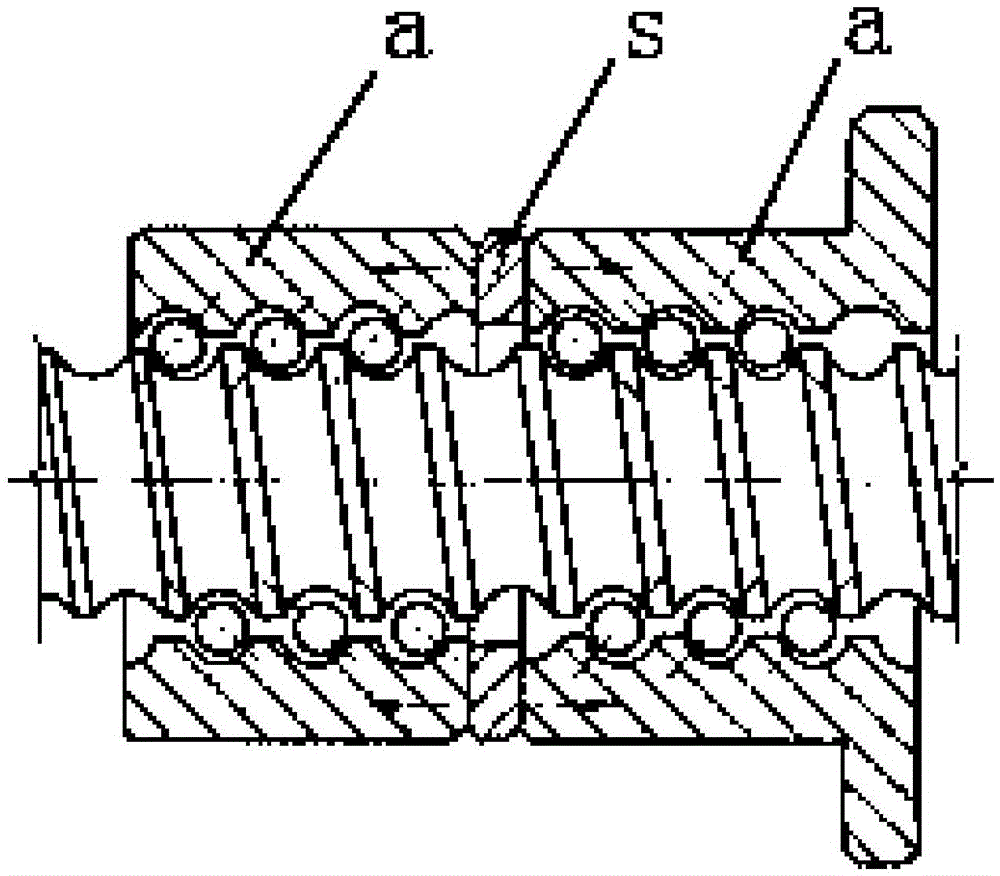

[0029] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com