Equipment for testing airtightness and pressure resistance of shield tail brush of shield tunneling machine

A technology of pressure resistance test and shield tail brush, applied in the field of shield machine, can solve the problems that pressure resistance sealing performance affects sealing safety, there is no uniform testing standard for pressure resistance performance of shield tail sealing brush, and product performance cannot be judged. Improve service life and avoid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments.

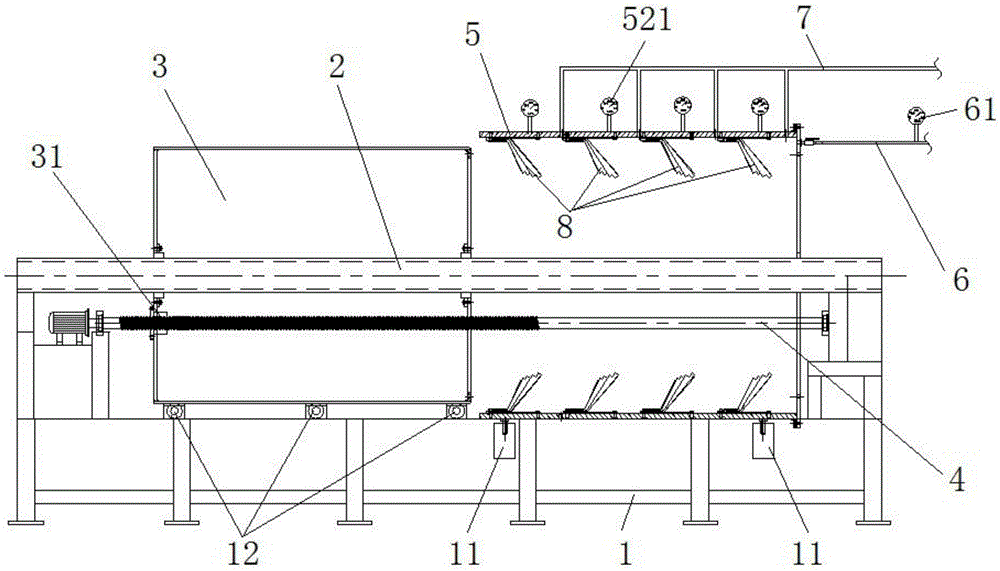

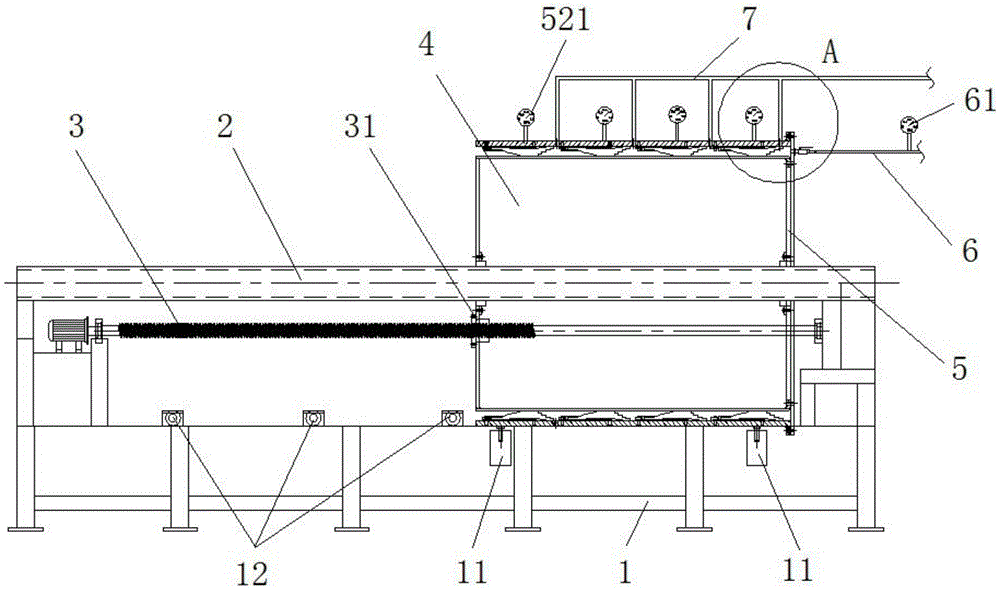

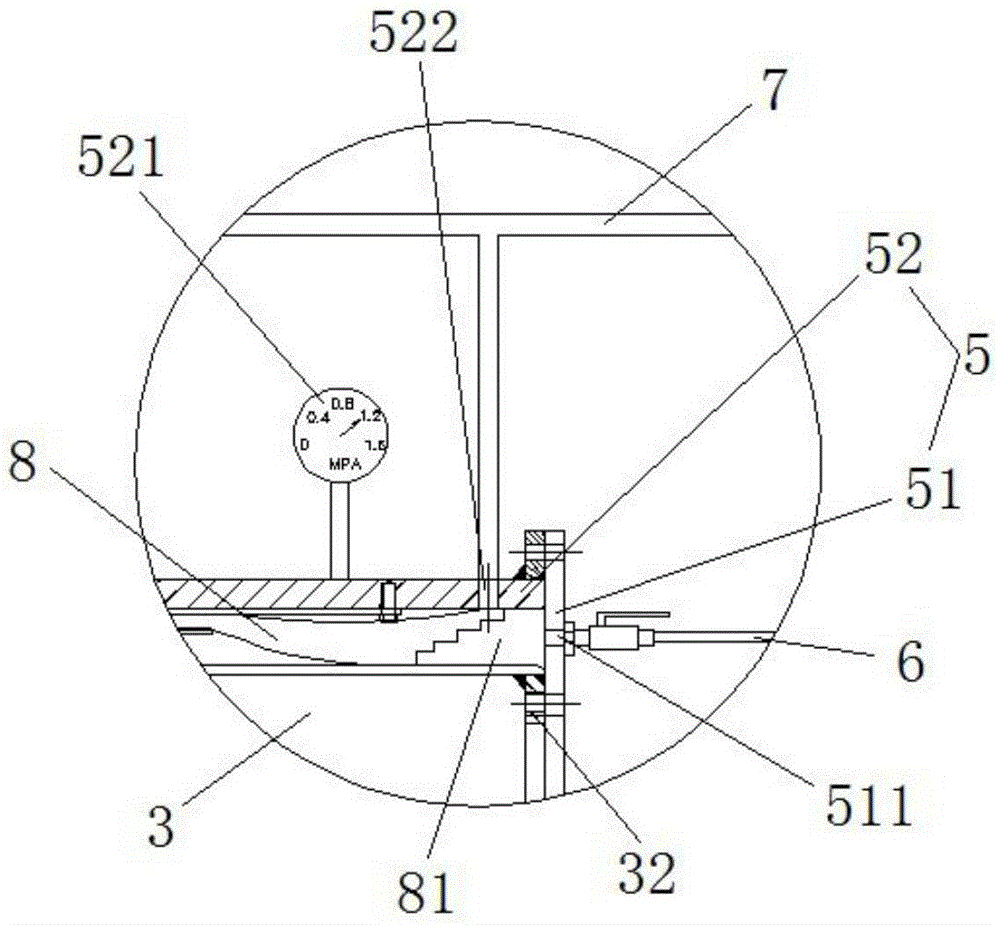

[0031] Such as Figure 1 to Figure 3 As shown, a shield tail brush seal pressure test equipment of a shield machine includes a base 1, a core rod fixed horizontally above the base 1, a test tube piece 3 sleeved on the core rod 2, and a parallel pivot connection The drive screw 4 on the side of the mandrel 2 and the assembly jig 5 on the side of the test tube 3; the drive screw 3 passes through the test tube 3, and the test tube 3 is fixed with a screw sleeve engaged with the drive screw 2 31; The assembling fixture 5 is a cylindrical structure open to the side of the test tube 3, including a disc body 51 through which the core rod 2 and the drive screw 3 pass, and a cylinder body 52 fixed on one side of the disc body 51, and the disc body 51 A water injection port 511 is provided on the water injection port 511, and a water injection pipe 6 is connected to the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com