Vibration reaction force active balancing device for vibration-acceleration test equipment

A test equipment and reaction force technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve problems such as the deterioration of the working environment of the centrifuge spindle, aggravating the impact of the centrifuge spindle, and increasing the vibration of the centrifuge spindle. , to achieve the effect of expanding the frequency range of use, improving the rotation accuracy, and reducing the overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

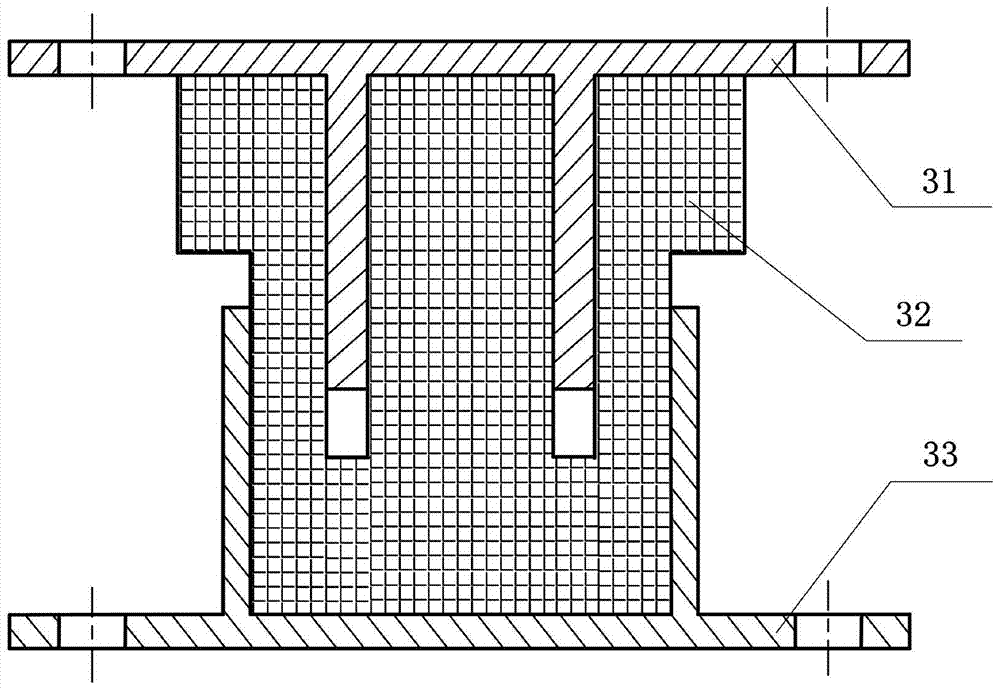

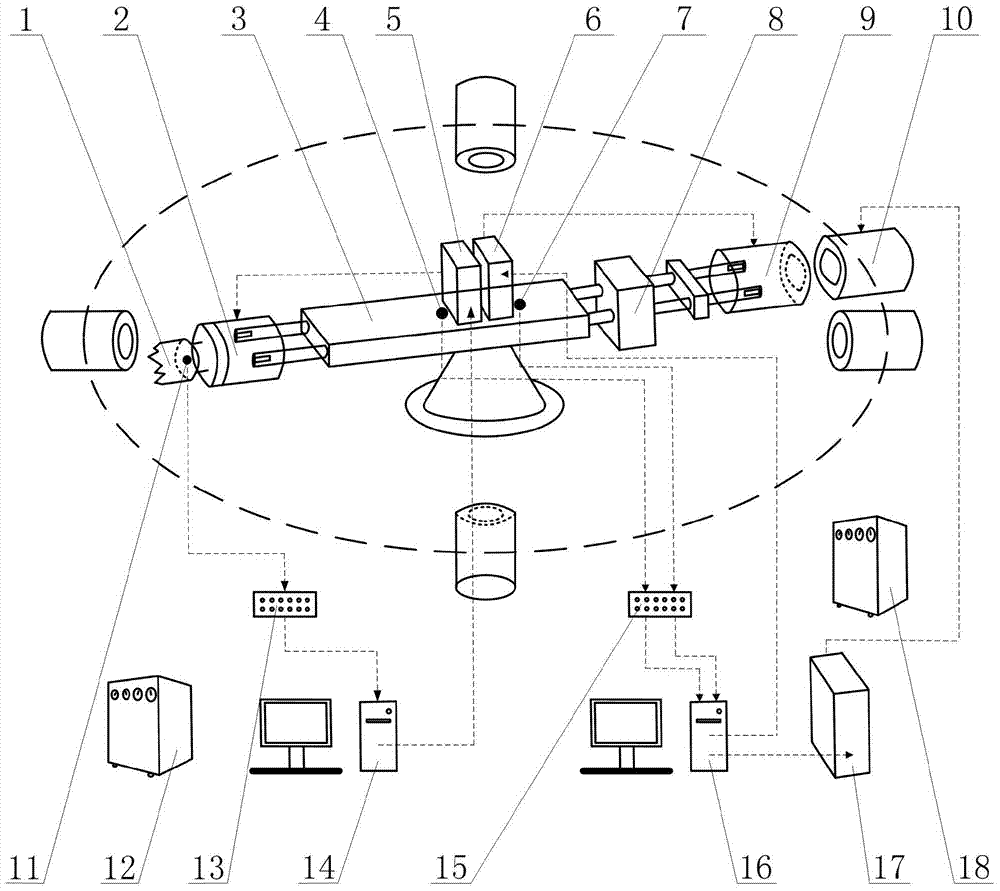

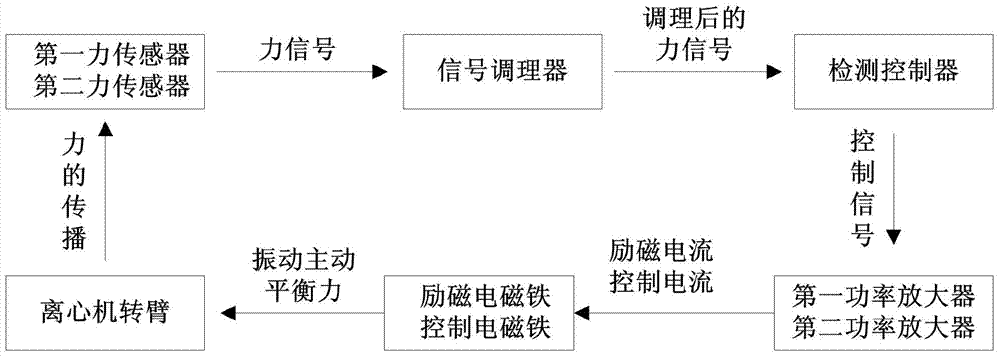

[0034] Such as figure 2 and image 3 As shown, the vibration-acceleration test equipment of the present invention comprises a centrifuge 3, a vibrating table 2 and a counterweight 8, and the vibrating table 2 and the counterweight 8 are installed on the rotating arm (not marked among the figures) of the centrifuge 3 respectively. Both ends are located on both sides of the main shaft of the centrifuge 3 (below the rotating arm, not marked in the figure), and the vibration-acceleration test equipment of the present invention uses a vibration reaction force active balance device comprising an excitation electromagnet 9 and a control electromagnet. 10. The first force sensor 4, the second force sensor 7, the signal conditioner 15, the detection controller 16, the first power amplifier 6 and the second power amplifier 17, and the excitation electromagnet 9 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com