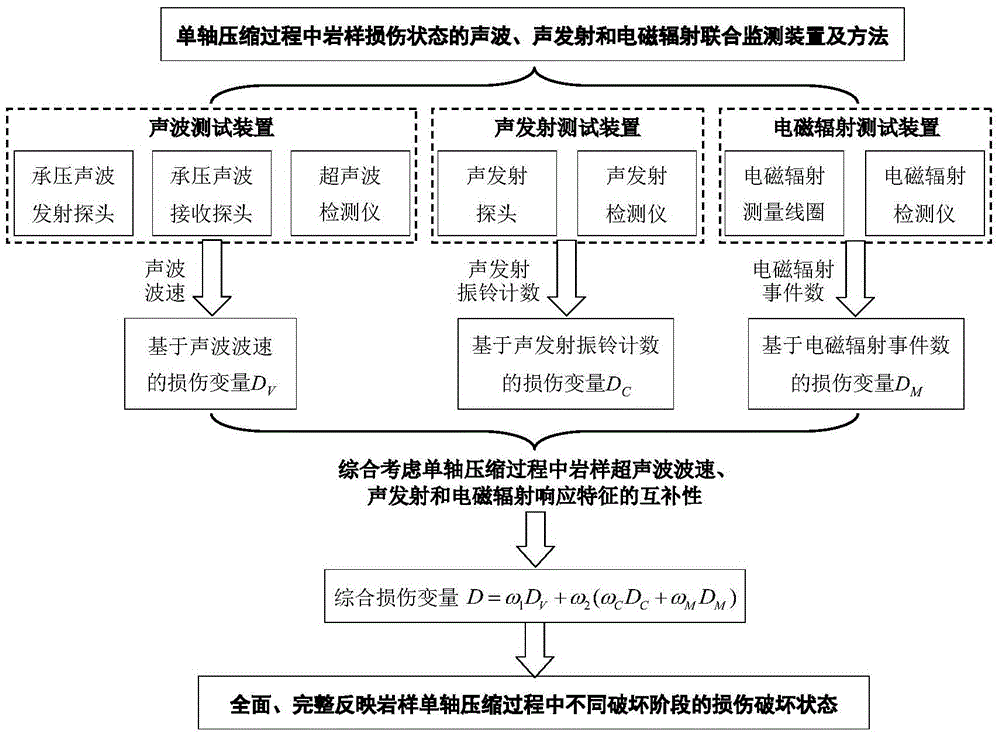

Device and method for monitoring rock sample damage in uniaxial compression process

The technology of a uniaxial compression and monitoring device is applied in the field of rock mechanics laboratory test, which can solve the problems of insufficient reflection of microscopic damage and failure to reflect damage and damage well, and achieves simple and convenient production, shielding the interference of electromagnetic radiation noise, The effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

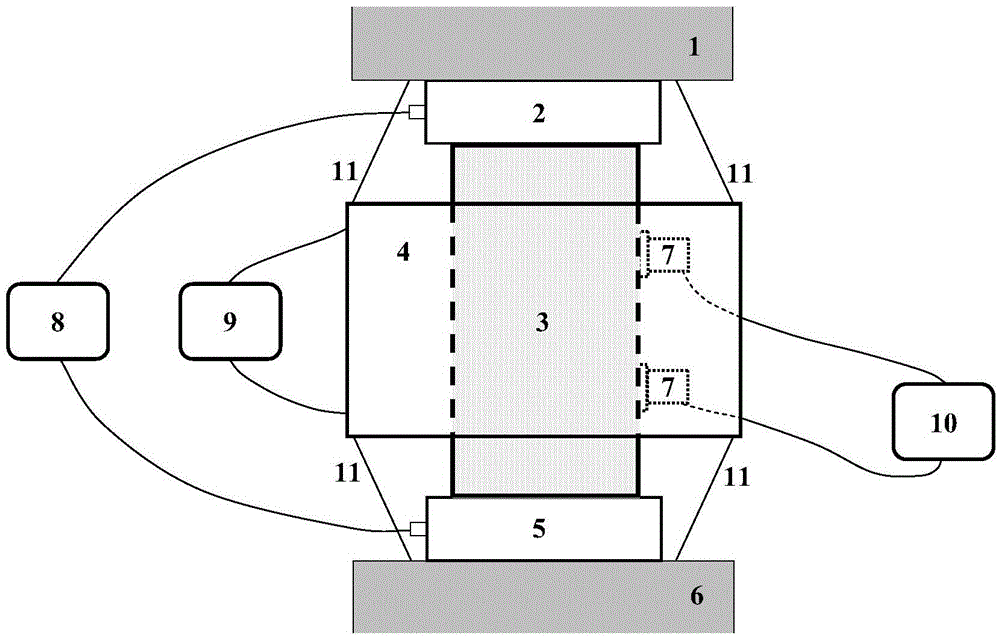

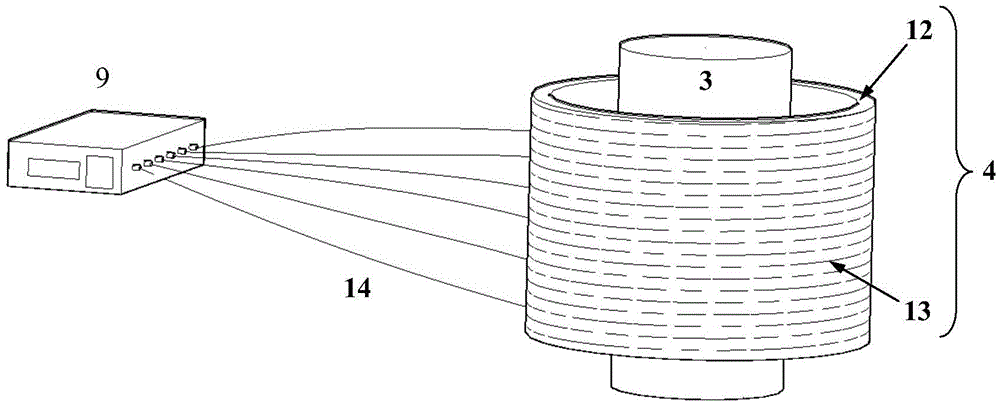

[0044] Such as figure 1 As shown, it is a schematic diagram of an acoustic wave, acoustic emission and electromagnetic radiation joint monitoring device for rock sample damage in the uniaxial compression process described in the embodiment of the present invention, mainly including: acoustic wave testing device, acoustic emission testing device, electromagnetic radiation testing device The acoustic wave testing device comprises a pressure-bearing acoustic wave transmitting probe 2, a pressure-bearing sound wave receiving probe 5, an ultrasonic detector 8; the acoustic emission testing device comprises a plurality of acoustic emission probes 7 and an acoustic emission detector 10; the electromagnetic radiation The test device includes an electromagnetic radiation measuring coil 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com