Mixed core testing chamber and mud rock breakthrough pressure testing device

A technology for testing chambers and cores, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of not considering the capillary end effect, difficult to observe the water at the outlet end, and not considering the flow of oil and gas, etc. To achieve the effect of simple structure, cheap equipment, accurate and real breakthrough pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

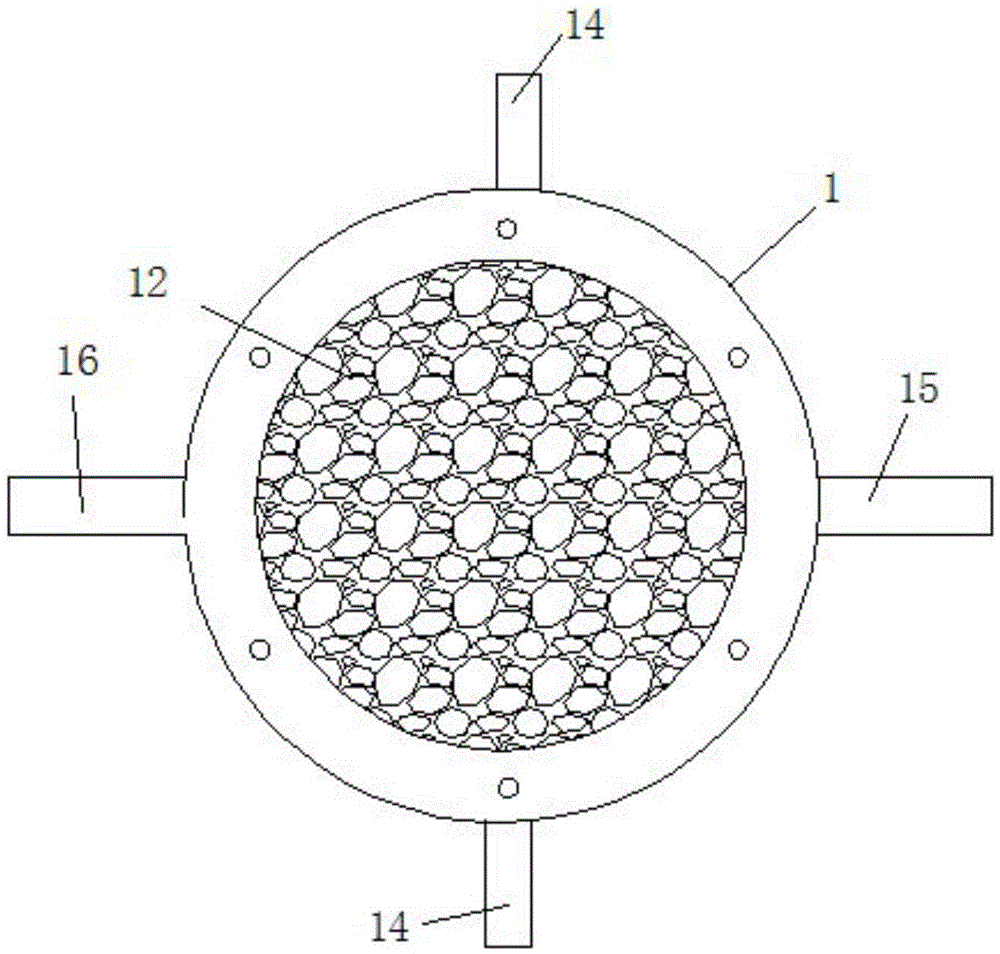

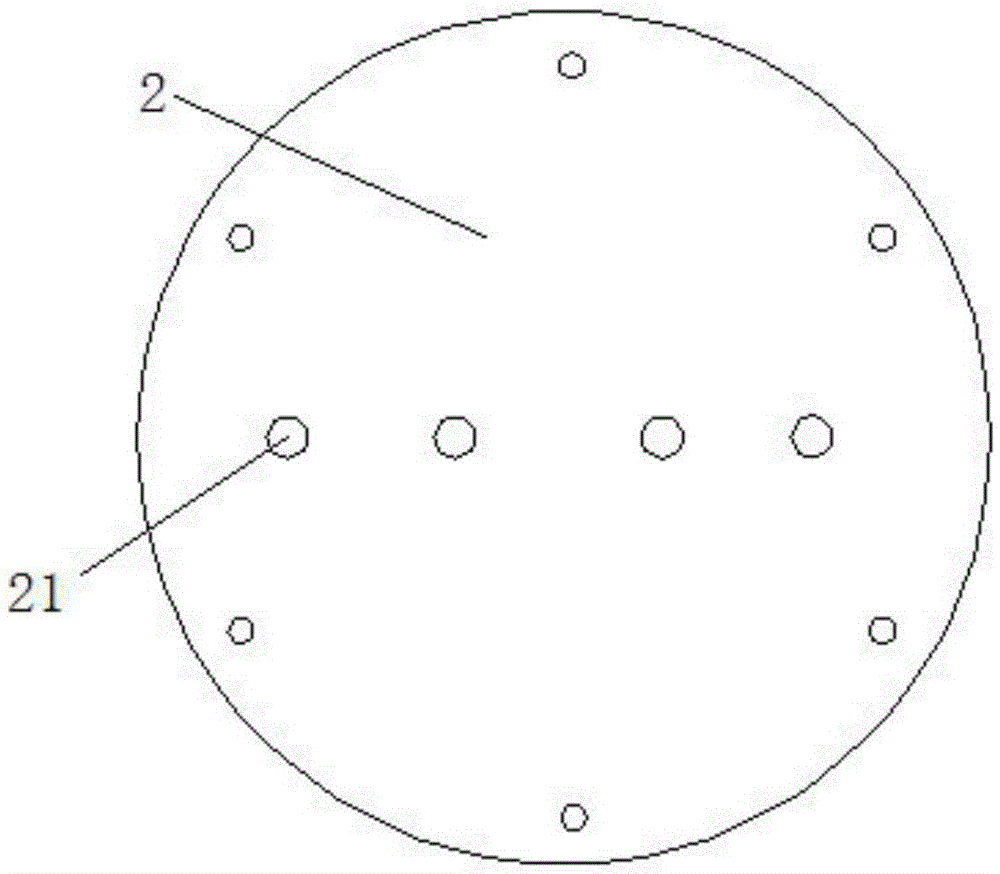

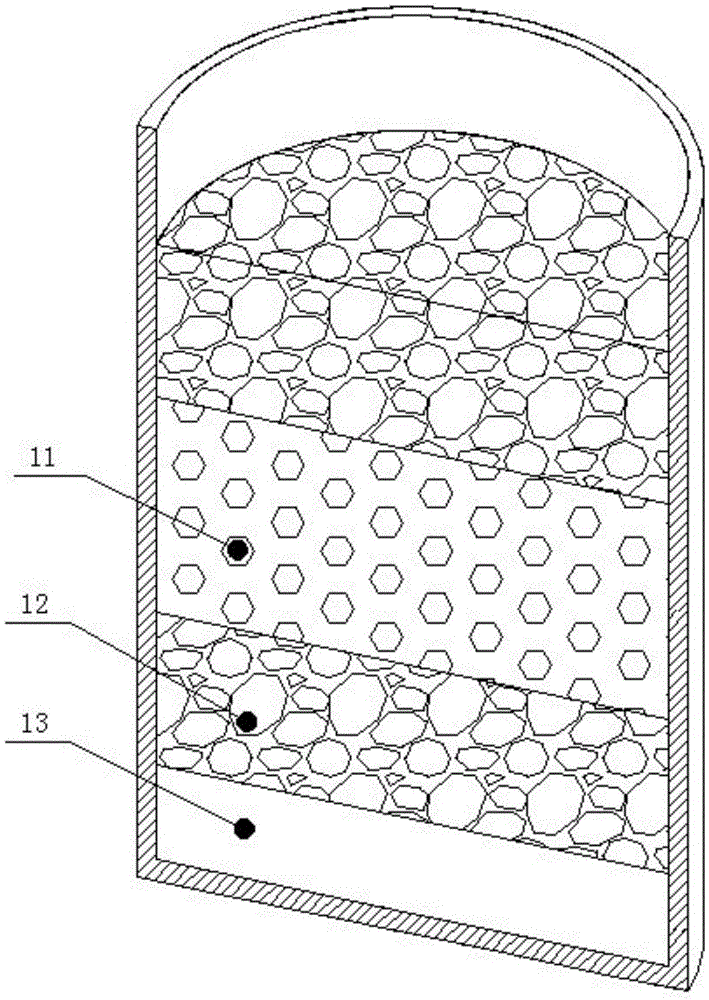

[0028] Such as figure 1 , figure 2 image 3 As shown in and , a mixed rock core test chamber is roughly cylindrical, cuboid or other shapes, including a cavity 1 with one end open, and the open end of the cavity is detachably provided with a cover 2 for sealing the cavity 1. This implementation In the example, the cavity 1 and the cover 2 form a cylindrical mixed core test chamber, which are connected by positioning pins and nuts. The middle part of the cavity 1 is provided with a sandstone layer 11 along the horizontal direction, and the upper and lower sides of the sandstone layer 11 are symmetrically provided with mudstone layers 12, and there is a space between each of the mudstone layers 12 and the adjacent end of the cavity 1. There is reserved space 13. A water injection port 14 communicating with the reserved space 13 is provided on the cavity wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com