Automatic calibration device for dust concentration on-line monitoring

A technology for automatic calibration and dust concentration, which is used in measurement devices, suspension and porous material analysis, particle suspension analysis, etc. It can solve the problems of complex structure and inconvenient on-site maintenance, achieve simple and compact structure, realize automatic calibration, and reduce labor. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

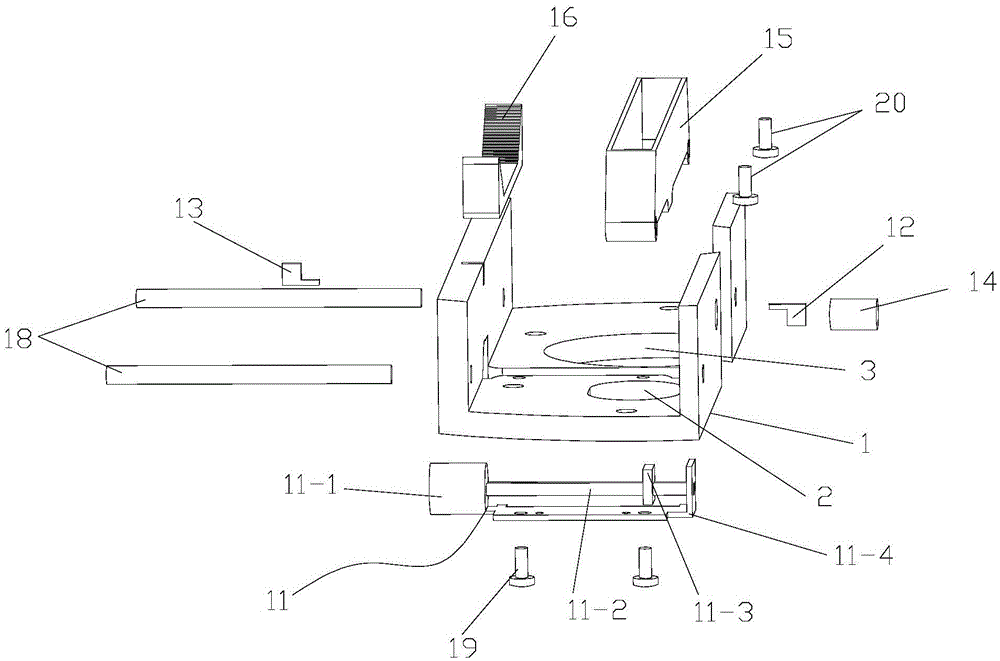

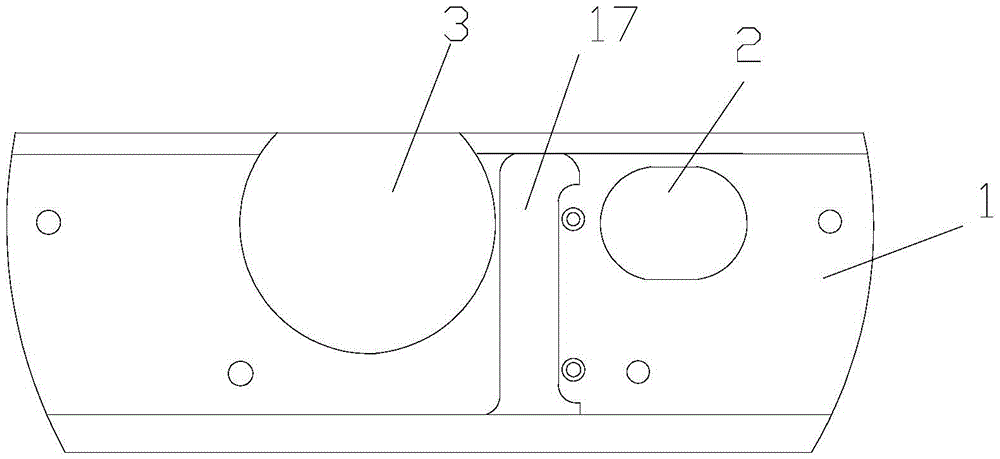

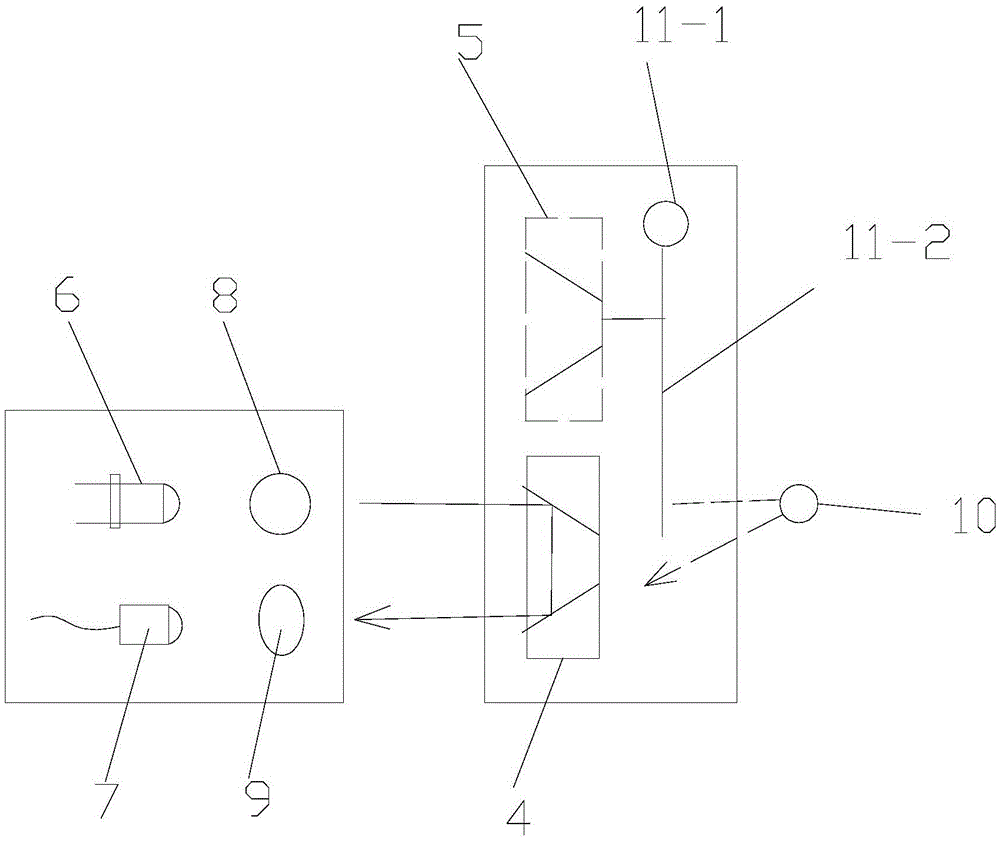

[0024] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the bottom plate structure of the calibration frame in the present invention, image 3 It is a schematic diagram of the working state of the present invention, image 3 The dotted line in the middle represents that the calibration unit is located at the measurement position, and the solid line represents that the calibration unit is located at the calibration position, as shown in the figure: the automatic calibration device for on-line monitoring of dust concentration in this embodiment includes a calibration frame 1 and is set on the calibration position in a laterally movable manner. The calibration unit on the frame 1, the calibration frame 1 is provided with the emission light hole 2 and the reception light hole 3, the lateral movement position of the calibration unit includes the calibration position 4 and the measurement position 5; Composed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com