Magnetic suspension-based detection apparatus and detection method for defects of parts

A detection device and detection method technology, applied in the direction of measuring device, material magnetic variable, material analysis through electromagnetic means, etc., can solve the problems of high detection cost and cumbersome detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the present invention more clearly understood, the present invention will be further described below according to specific examples and accompanying drawings of the present invention.

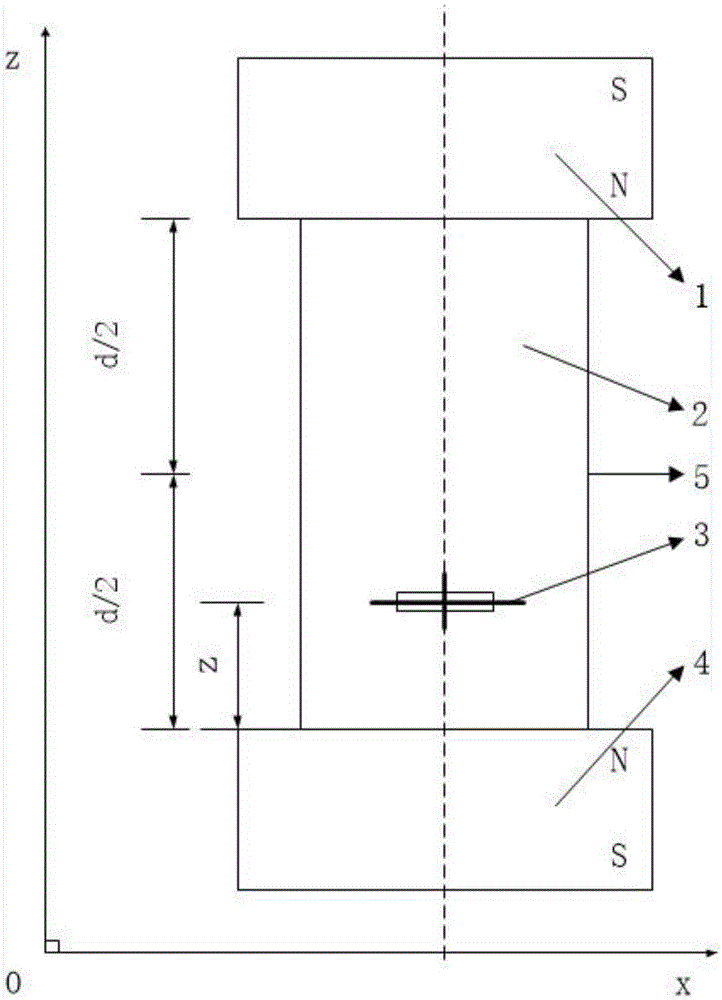

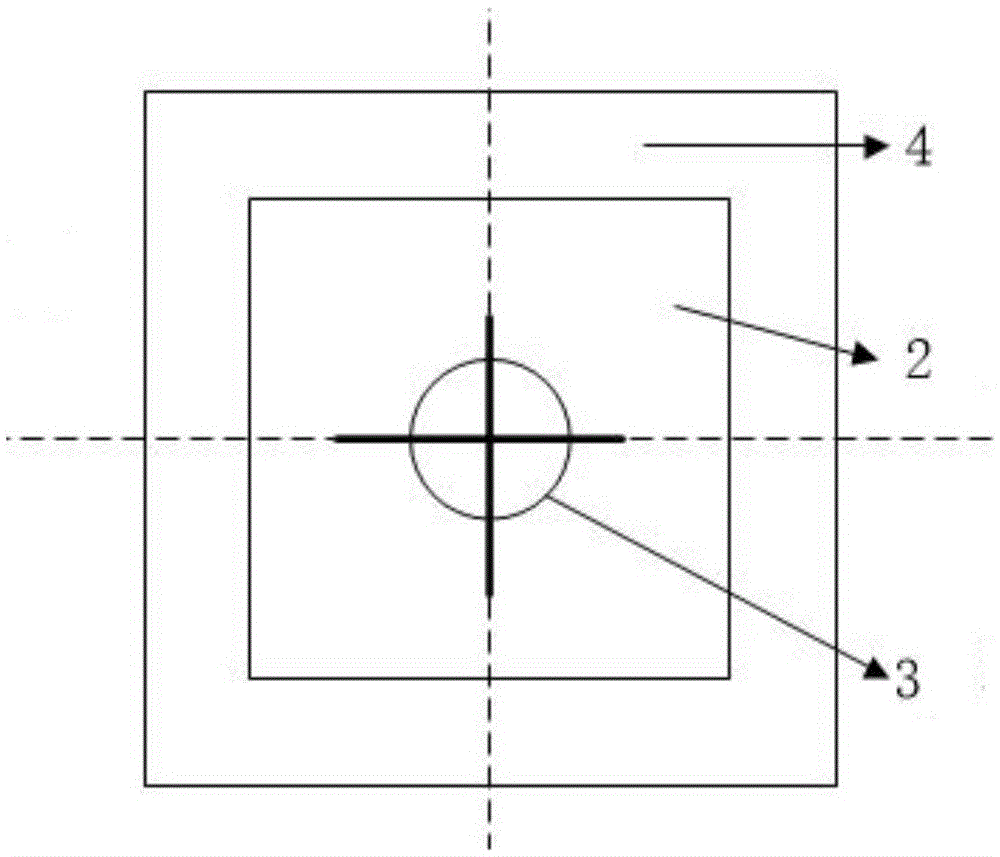

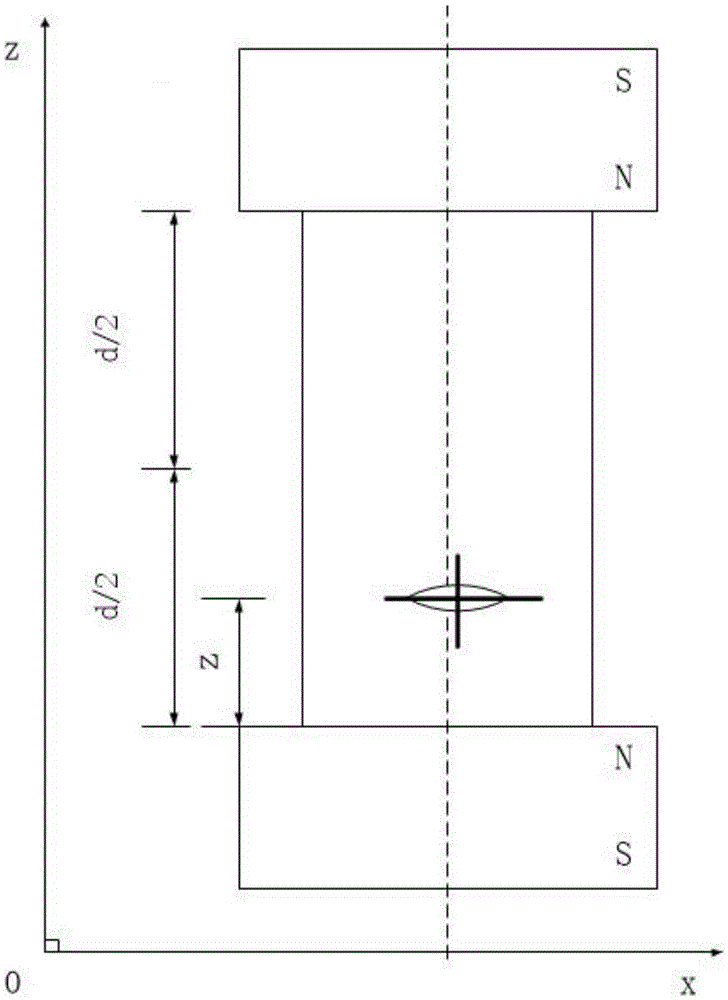

[0049] Such as figure 1 and figure 2 Shown is the principle diagram of the magnetic levitation device of the present invention, including a magnet 1, a magnet 4, a medium solution 2, a sample 3, and a detection container 5. The magnet 1 and the magnet 4 are coaxially arranged in the vertical direction, and the same poles are oppositely arranged, figure 1 In the above, the N poles of the two magnets are arranged oppositely, both facing the detection container.

[0050] The detection container 5 is a transparent container with an upper opening, generally made of materials such as glass and plastic.

[0051] The magnetic induction of magnet 1 and magnet 4 on the surface of the N pole is the same, generally 0.3T-0.6T. In this embodiment, the magnetic induction of magnet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com