Automatic production scheduling optimization management information model based on big data analysis and processing technology

A technology for analyzing, processing and managing information, which is applied in the field of inventory optimization management system, can solve problems such as high operating costs, suppress efficient operation of supply chain, supply chain fluctuations, etc., and achieve the effect of reducing capital occupation, improving efficiency, and reducing finished product inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

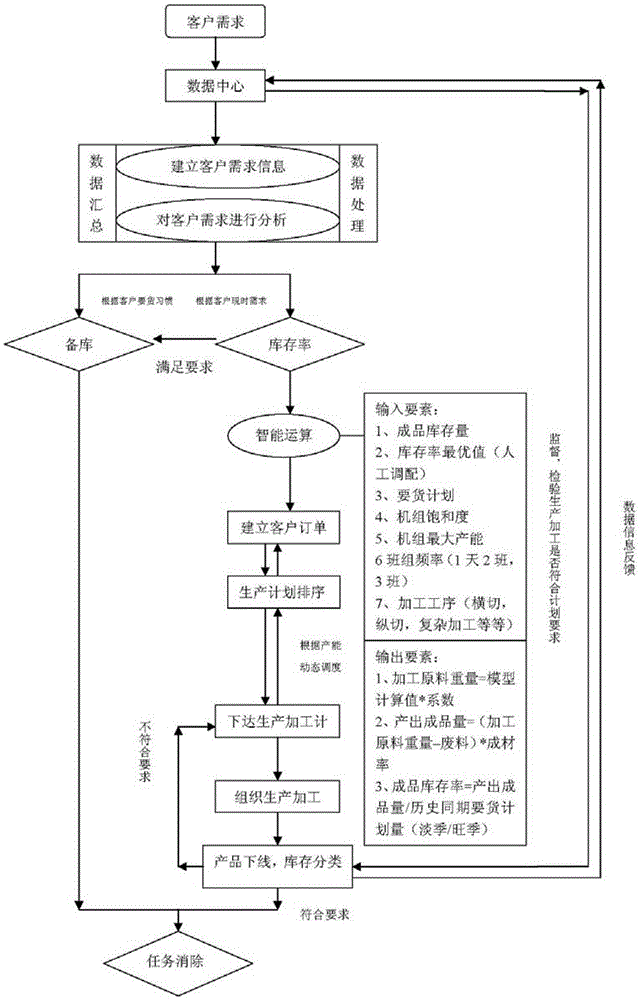

[0023] figure 1 The automatic scheduling optimization management information model based on big data analysis and processing technology shown in , its construction method includes customer demand information collection module, customer information processing module, production planning scheduling module, inventory classification module, the specific steps are:

[0024] 1) Receive the customer's demand plan and establish customer demand information. Customer demand information includes supply contracts, planned output of models, unit consumption of items, models of items, quantities of items, time requirements, etc.

[0025] 2) Summarize the data to the data exchange center to classify and process customer information. That is to classify and count all customer information combined with historical big data to determine the required q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com