Multi-core industrial cable

An industry and cable technology, applied in the field of power cables, can solve the problems that the cable material or structure cannot meet the needs of the industry, and achieve the effect of simple and reasonable structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The invention will be further described below in conjunction with the accompanying drawings.

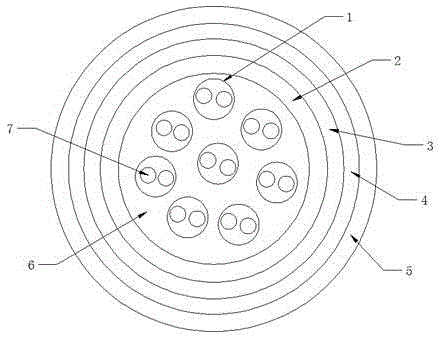

[0008] A multi-core industrial cable, including a cable core 1, a wrapping layer 2, an armor layer 3, a shielding layer 4, a flame-retardant sheath 5, a conductor 7 and a filler 6, and the conductor 7 is wrapped with a wrapping material to form a cable The core 1, the cable core 2 is extruded to wrap around the cladding 2, the cladding 2 is extruded to wrap the armor layer 3, the armor layer 3 is extruded to wrap the shielding layer 4, and the shielding layer 4 is extruded A flame retardant sheath 5 is wrapped, a filler 6 is provided between the cable core 1 and the wrapping layer 2, the armor layer 3 is made of steel strip, and the shielding layer 4 is made of copper wire , the flame-retardant sheath 5 is made of low-smoke halogen-free flame-retardant material, and the filler 7 is made of glass fiber.

[0009] Although the specific embodiments of the present invention have b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com