Radiant heat pad and method for manufacturing the same

A manufacturing method and technology of heat dissipation pad, which are applied in cooling/ventilation/heating transformation, housing with display/control unit, electrical components, etc., which can solve the problem of occupation, thickening of liquid crystal display device thickness, and difficulty in heat dissipation design of internal components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the heat dissipation pad and its manufacturing method of the present invention will be described with reference to the accompanying drawings.

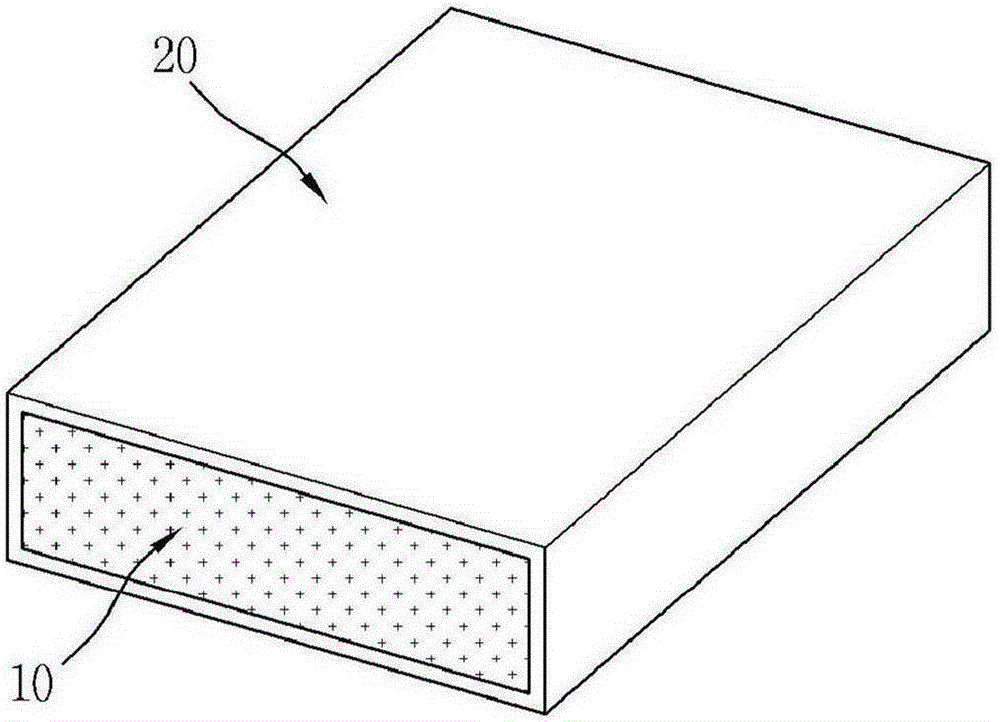

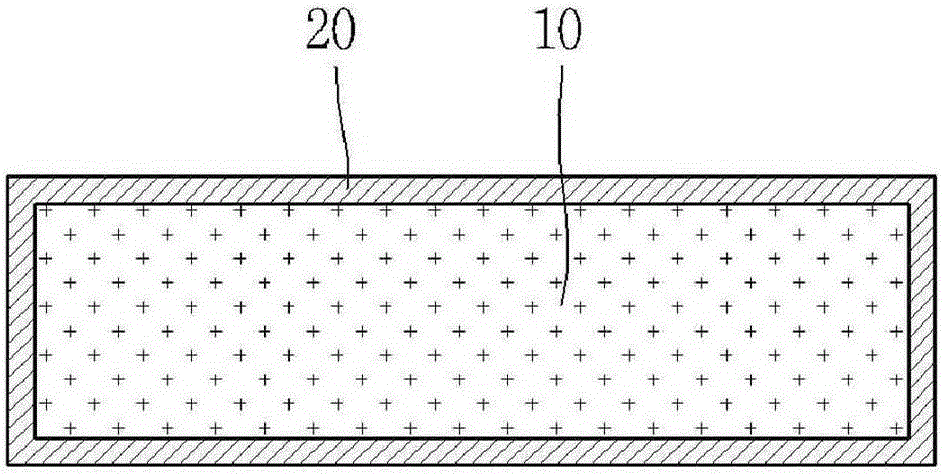

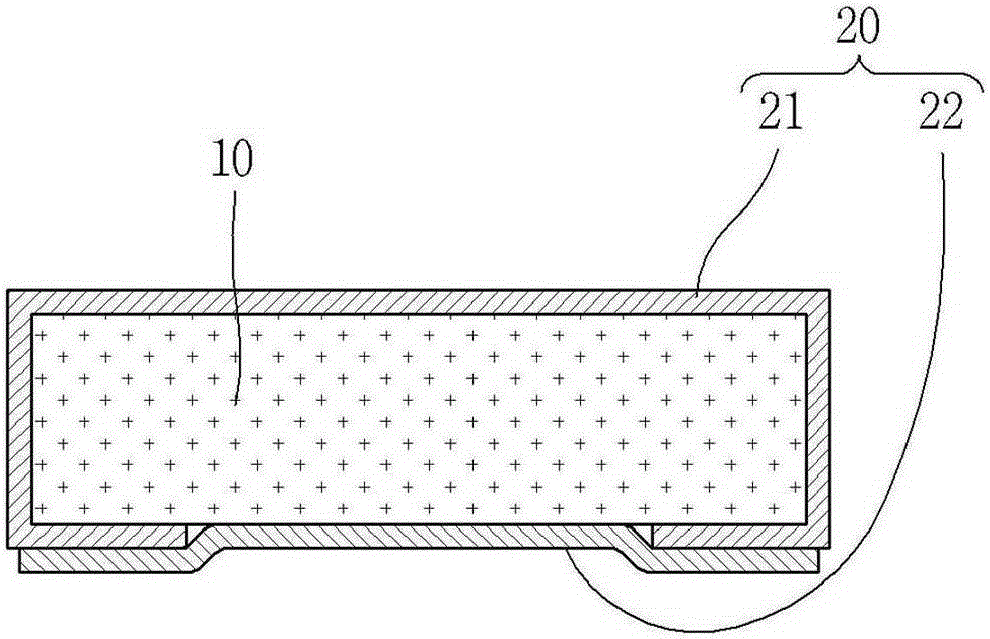

[0020] figure 1 It is a perspective view showing an embodiment of the heat dissipation pad of the present invention. figure 2 It is a sectional view showing an embodiment of the heat dissipation pad of the present invention.

[0021] Such as figure 1 , 2 As shown, an embodiment of the heat dissipation pad of the present invention includes a base member 10 and a heat dissipation film 20 .

[0022] Preferably, the base member 10 is made of an elastic material that contracts when pressed and recovers after being released. More preferably, the base member 10 is a porous material having elastic force and having a plurality of holes inside to allow air to flow. As an example of the base member 10, the base member 10 is preferably made of a sponge material. The base member 10 is preferably formed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com