Automatic loading and feeding trolley for meat pigeon breeding farm

A technology of automatic feeding and breeding farms, which is applied in poultry farming, application, animal husbandry, etc., and can solve problems such as the expansion of breeding scale that affects the interests of farmers, the increase in the cost of meat pigeon breeding, and the lack of feed for meat pigeons. , to achieve the effect of reducing breeding costs, requiring less plant construction, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

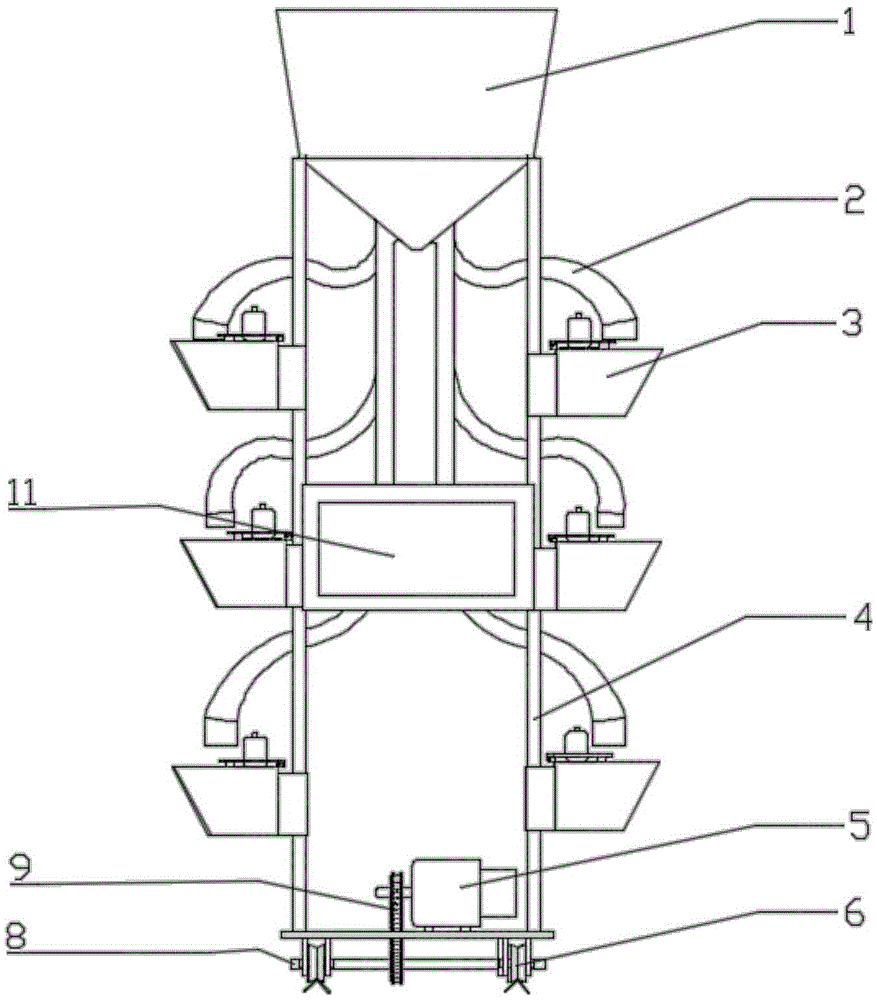

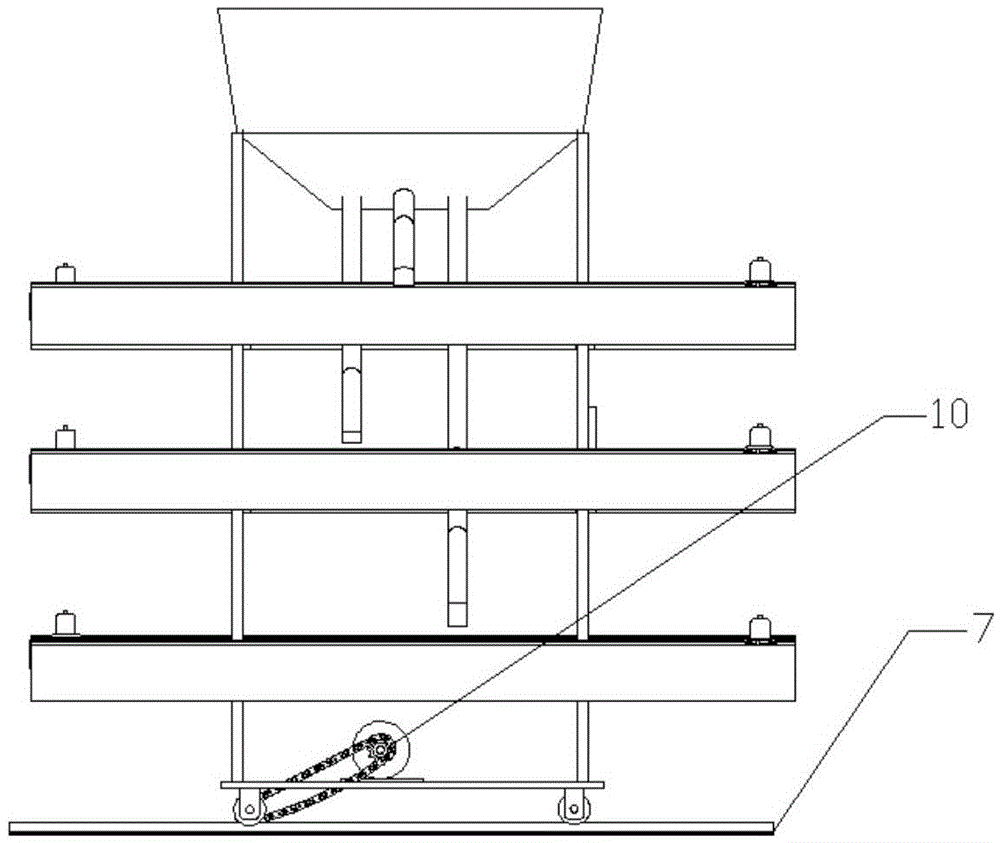

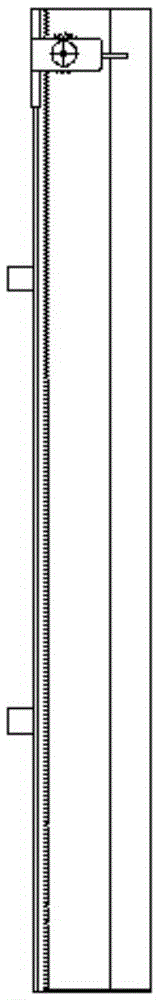

[0018] An automatic feeding device for a meat pigeon farm is composed of an upper hopper 1, a feeding pipe 2, a trough 3, a vehicle frame 4, a reduction motor 5, a wheel 6, a guide rail 7, a transmission shaft 8, a chain 9, a sprocket 10, Composed of controller 11, the upper hopper 1 is composed of electromagnet 101, telescopic rod 102, baffle 103, baffle frame 104, and the trough 3 is composed of motor 301, slide rail 302, gear 303, The rack 304, the dial plate 305, and the connecting plate 306 are characterized in that: the upper hopper 1 is installed on the top of the vehicle frame 4, the six troughs 3 are installed on both sides of the vehicle frame 4, and the six feeding pipes 2 are composed of The upper hopper 1 is led out and installed directly above each trough 3, the controller 11 is installed in the middle of the vehicle frame 4, the sprockets 10 are respectively installed on the reduction motor 5 and the transmission shaft 8, and the two sprockets 10 are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com