Roof separation sensor calibrator

A roof separation layer and sensor technology, which is applied in the direction of instruments, tension measurement, measuring devices, etc., can solve the problems of damage to the reputation and interests of sensor manufacturers, failure to take measures in time, and different sensor accuracy, so as to achieve improved calibration efficiency and small impact. Calibration Accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

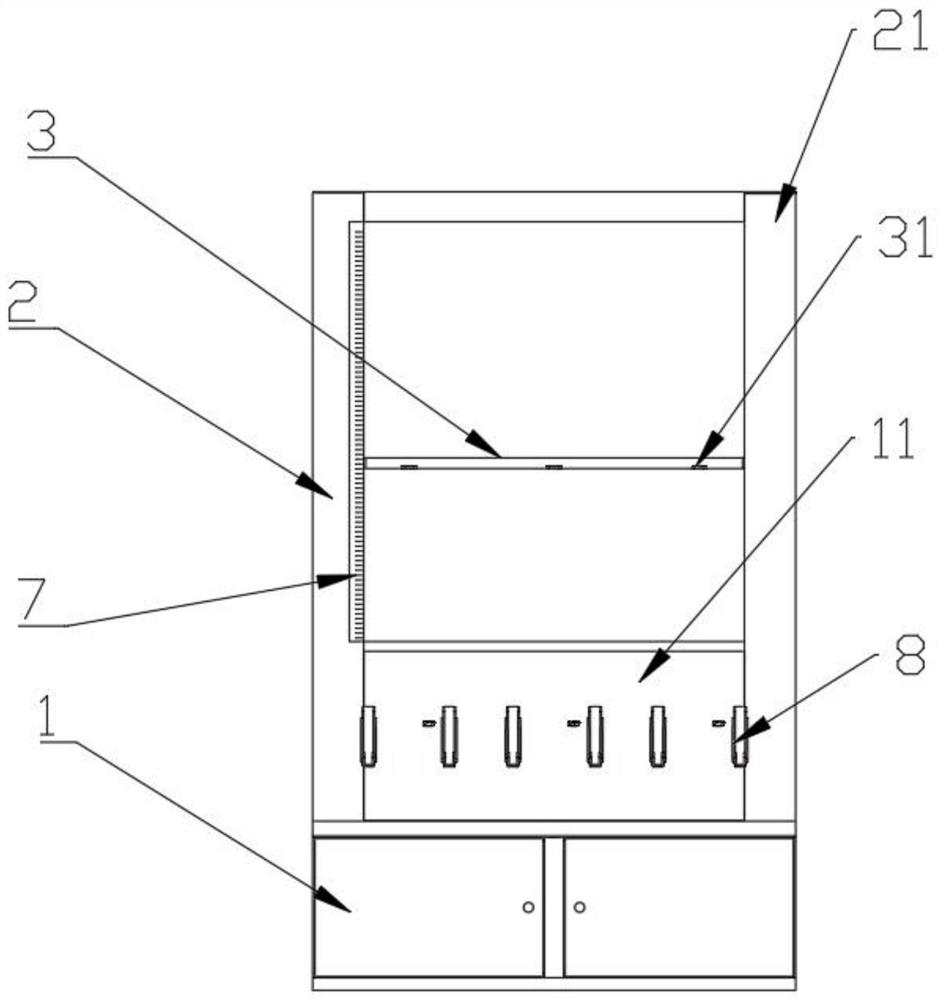

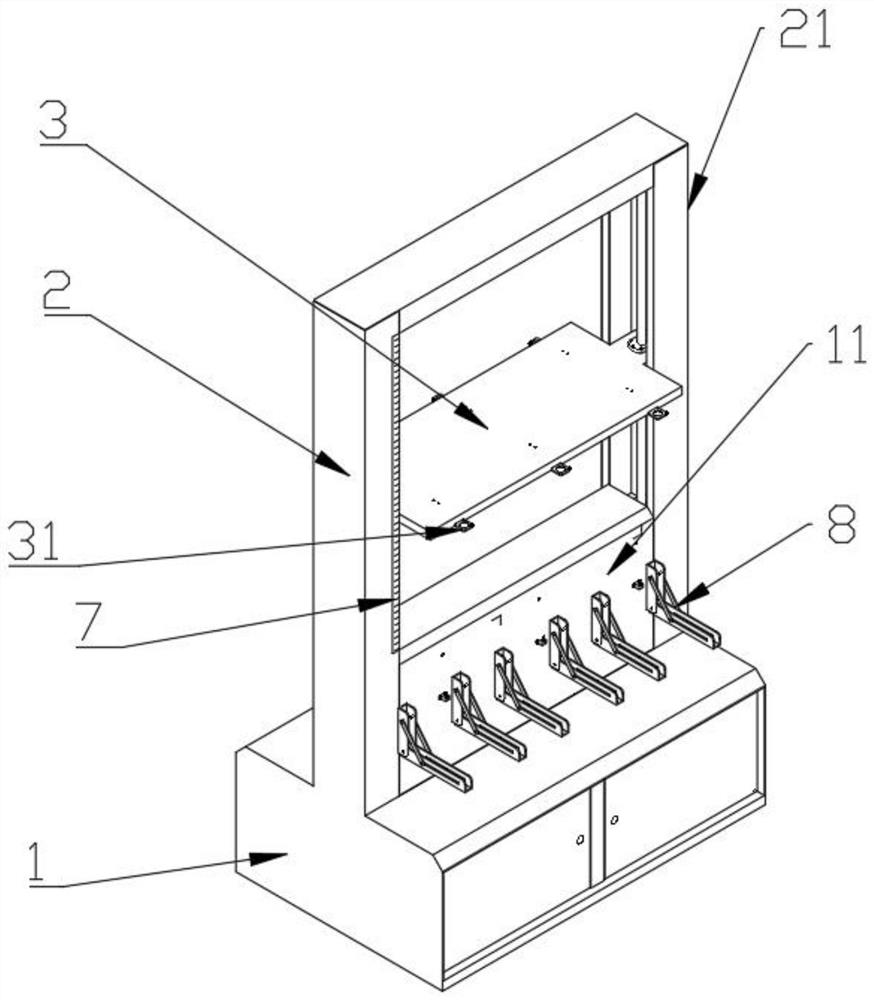

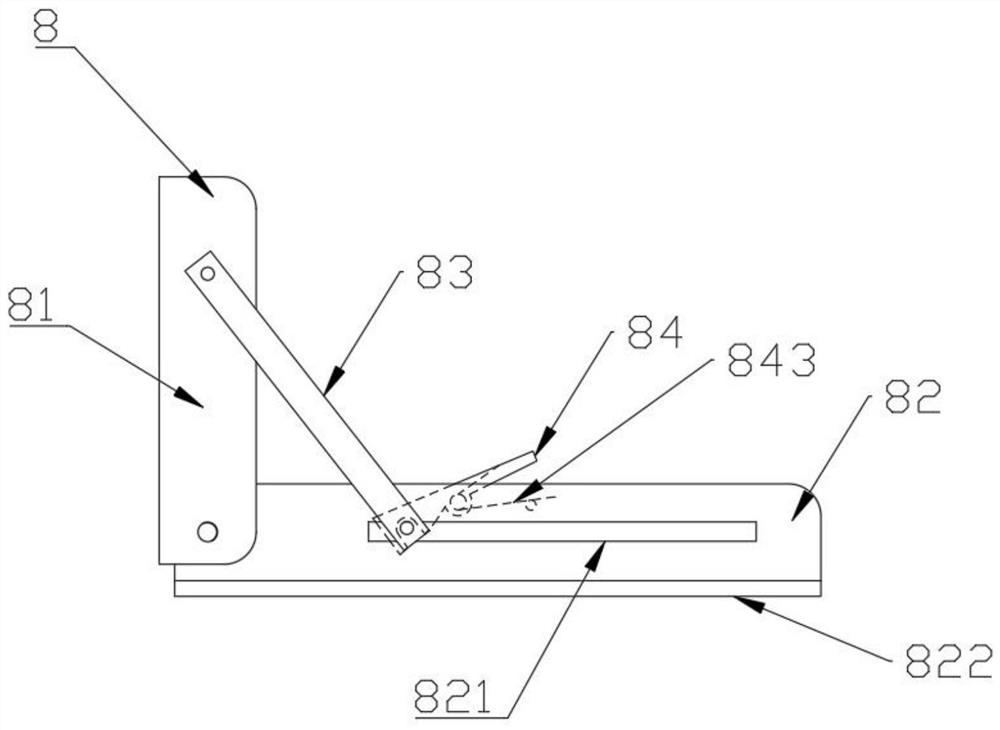

[0038] see Figure 1-Figure 2 , a roof detachment sensor calibration instrument, used to detect whether the accuracy of the roof detachment sensor 9 meets the standard, the roof detachment sensor 9 includes a rectangular sensor body 91 and a measuring tube 92 vertically arranged in the middle of the sensor body 91 , the measuring tube 92 is provided with a wire rope 93 for measuring the displacement distance, which is characterized in that it includes a base 1, a gantry 2 and a central control computer, and the gantry 2 includes two vertical frames 21, and the two vertical frames 21 is vertically arranged on both sides of the base 1, and a vertical lead screw 4 is respectively arranged in the two vertical frames 21, and the lower ends of the two lead screws 4 are synchronously rotated and connected by a horizontal bar 5, and the horizontal bar 5 is driven and rotated by the motor 6, and a lifting platform 3 is arranged between the two leading screws 4, and the lifting platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com