Chain belts and chain belt pattern forming method

A pattern and chain belt technology, applied in clothing, printing, fasteners, etc., can solve the problems of difficult to see, invisible light-colored printed patterns, a lot of man-hours, cost, etc., and achieve the effect of suppressing light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

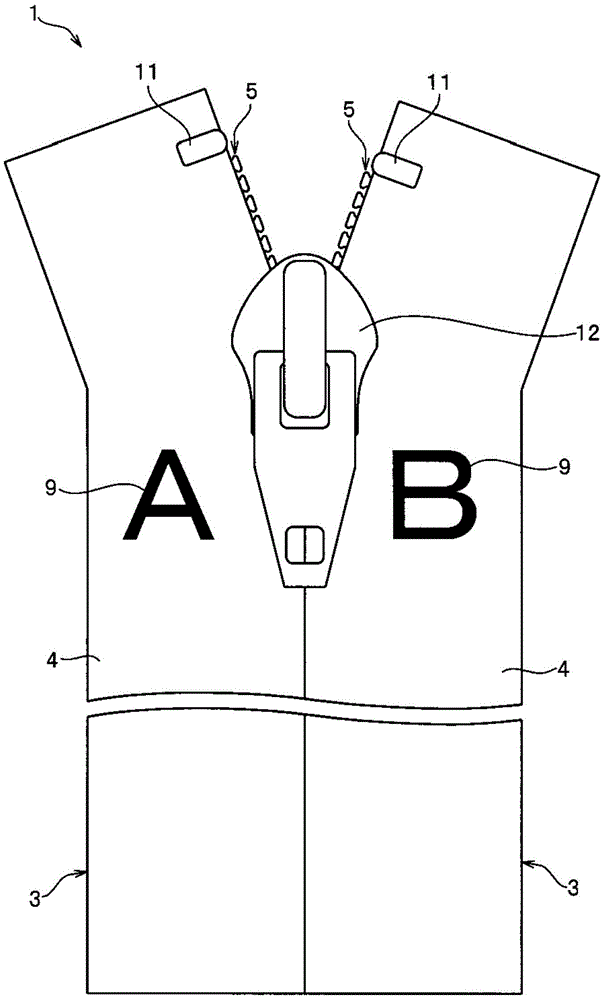

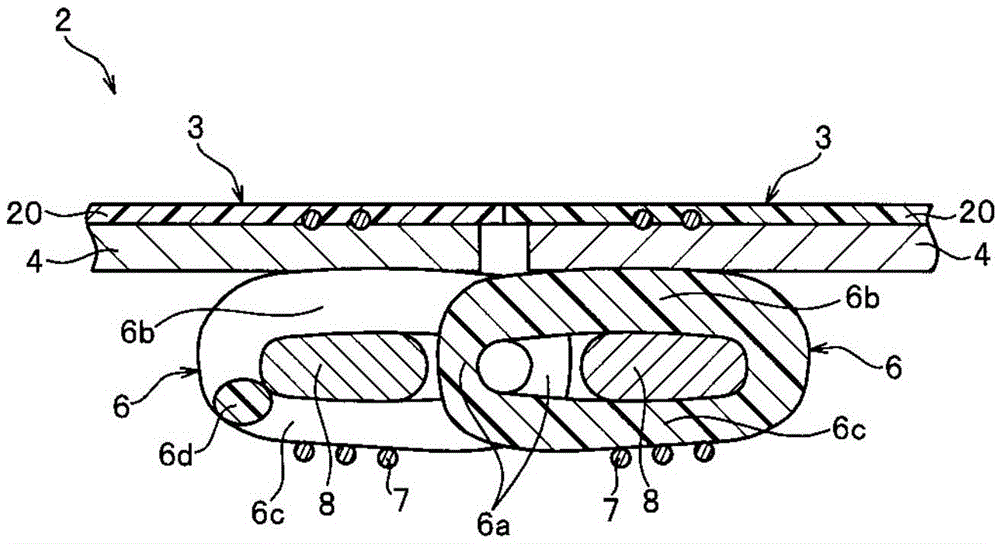

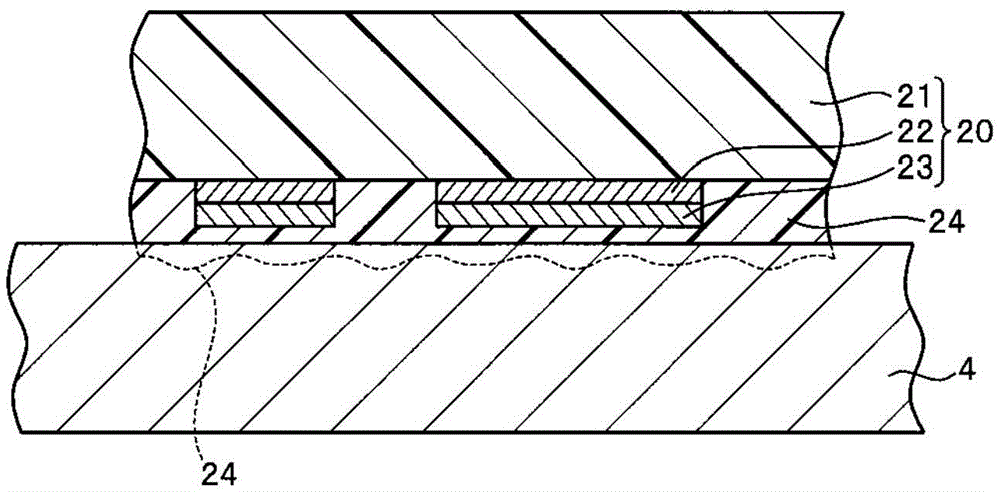

[0071] figure 1 It is a plan view showing the slide fastener of the present Example 1, figure 2 It is a sectional view of the fastener tape used for this slide fastener. image 3 It is an enlarged view of main parts showing enlargedly the bonded portion of the tape and the film member.

[0072] In addition, in the following description, the front-back direction means the tape length direction of a tape, and is the same direction as the sliding direction of a slider slide. In particular, the direction in which the slider is slid when the slide fastener is closed is defined as the front, and the direction in which the slider is slid when the slide fastener is opened is defined as the rear.

[0073] In addition, the left-right direction means the width|variety direction of a tape, and means the direction parallel to the tape surface of a tape and perpendicular|vertical to a tape length direction. In addition, the up-down direction refers to the front and back direction of the ...

Embodiment 2

[0126] Figure 6 It is a cross-sectional view showing the state before the film member is bonded to the tape in this Example 2.

[0127] In this second embodiment, when printing is performed on the film layer 21 to form the ink pattern portion 26 of the printed pattern, instead of using the pigment ink as in the above-mentioned embodiment 1, the dye ink that penetrates into the film layer 21 and is fixed is used. The film member 20a is formed. Therefore, in the film member 20a used in the present embodiment 2, the ink layer 22 like the aforementioned embodiment 1 is not formed between the film layer 21 and the cloth tape 4, but the structure other than that is the same as that of the aforementioned embodiment 1. Formed substantially in the same manner.

[0128] In addition, in the second embodiment, the third embodiment and the fourth embodiment described later, the description will focus on the configuration different from that of the first embodiment described above, and t...

Embodiment 3

[0135] Figure 7 It is a sectional view which shows the fastener tape of this Example 3.

[0136] The fastener tape 2 a of the present Example 3 has a pair of left and right fastener tapes 3 a, and each fastener tape 3 a has a tape 4 and an element row 5 formed along tape side edges of the tape 4 facing each other.

[0137] In this case, the fastener tape 2a of the third embodiment is formed in the form of a standard type (for the front) in which the element row 5 is attached to the tape front side of the cloth tape 4 and the element row 5 is exposed to the upper surface side of the slide fastener 1. .

[0138] Therefore, in the state where the core thread 8 penetrates between the upper leg part 6b and the lower leg part 6c of each fastener element 6, the fastener element 6 is sewn to the tape so that the lower leg part 6c contacts the tape 4. 4 on. In addition, the element line 5 itself of this Example 3 is formed similarly to the element line 5 of the said Example 1 menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com