H-type fracture reduction joystick

A joystick and crossbar technology, applied in the field of medical equipment, can solve the problems of medical personnel injury, time-consuming and labor-intensive, insufficient precision, etc., and achieve the effects of easy portability and storage, reduced exposure time, and quick assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

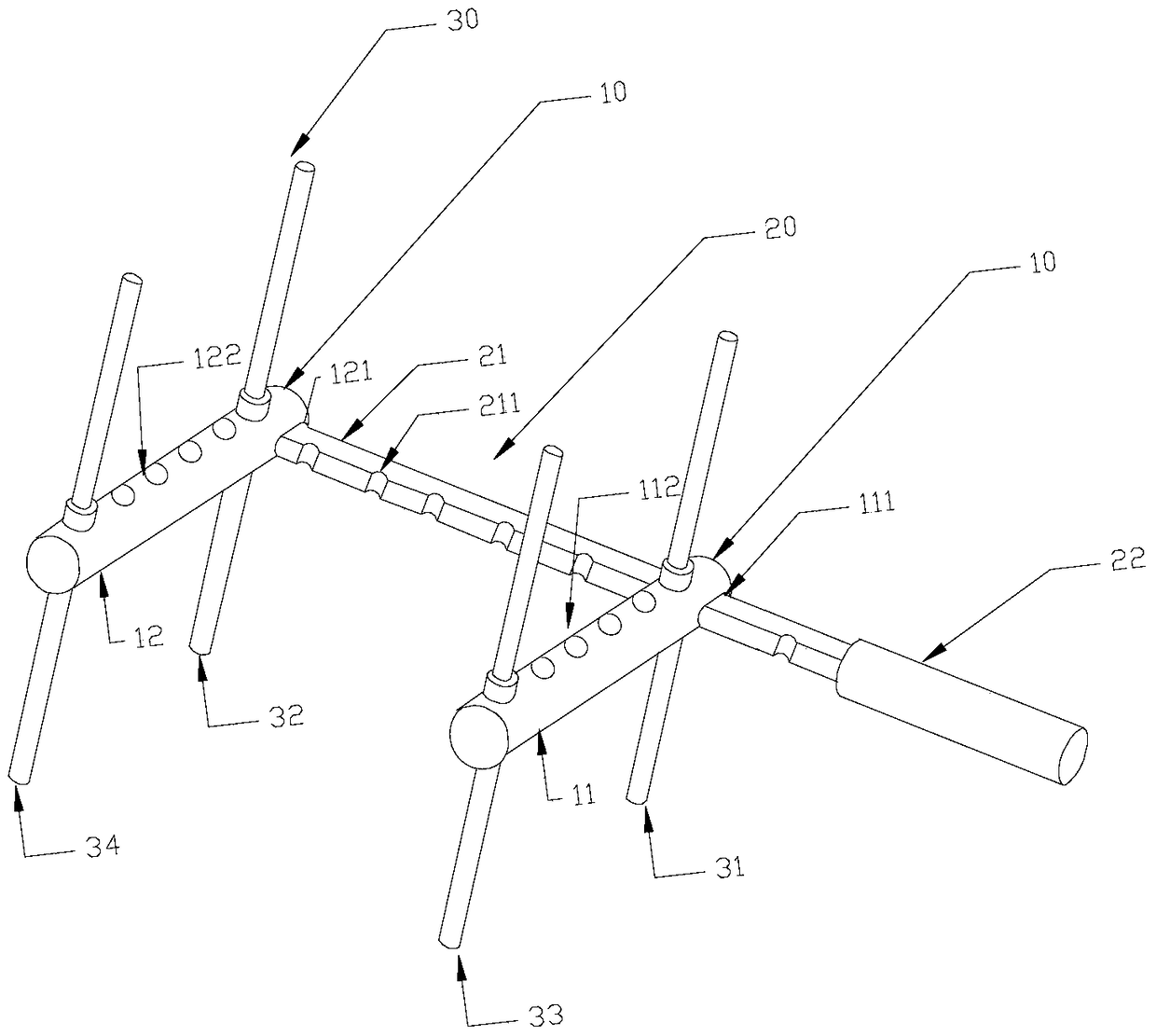

Embodiment 1

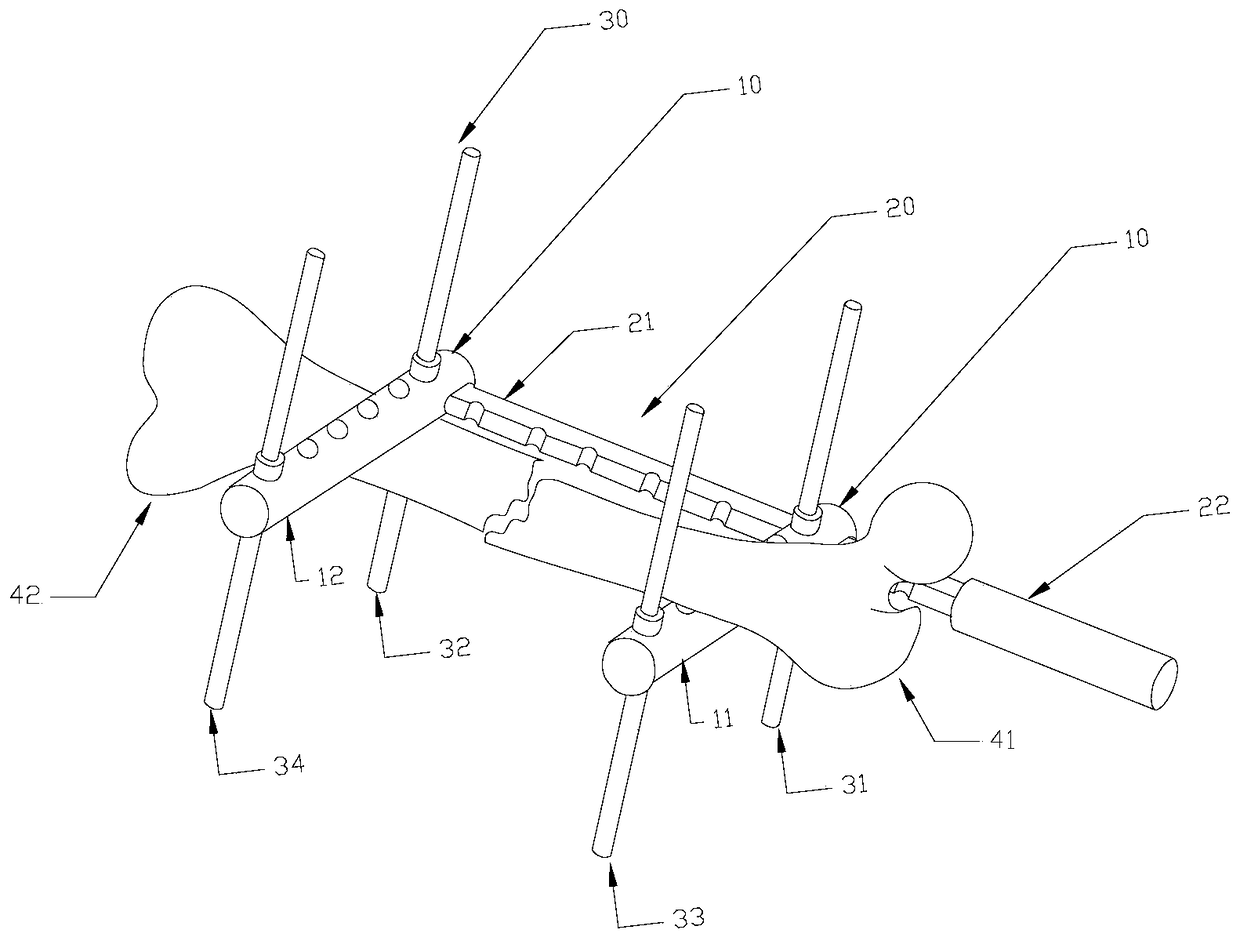

[0023] Embodiment one, such as figure 2 As shown, if the dislocation of the patient's fracture and bone is one-way up-down or one-way left-right dislocation, two cross bars 10, the main rod 20 and two auxiliary rods 30 can be used to realize the combination of the broken bone displacement. In this embodiment, the use of the joystick of the present invention is illustrated by taking the patient's fracture as an example where the broken bone 41 is lower and the broken bone 42 is higher. First, sterilize the required components at about 200°C. After cooling, insert the main operating rod 20 into the first through holes 111 and 121 on the same side of the two horizontal bars in turn. Select the main operating rod according to the length and thickness of the fracture site of the patient. Groove 211 at a suitable position on the 20, after the second through holes 112, 122 on the two crossbars are longitudinally aligned with the above-mentioned groove 211, insert the first subrod 31...

Embodiment 2

[0024] Embodiment 2, if the dislocation of the patient's fracture and bone is multi-directional dislocation at the same time up, down, left, and right, then it is necessary to use two crossbars 10, the main manipulation rod 20 and four auxiliary rods 30 to realize the displacement and combination of the broken bones. In this embodiment, the use of the H-type fracture reduction joystick of the present invention is illustrated by taking the multi-directional misalignment situation in which the broken bone 41 is lower to the left and the broken bone 42 is higher to the right as an example. On the basis of the components used in Embodiment 1, according to the thickness of the patient's fracture site, the third sub-rod 33 and the fourth sub-rod 34 are inserted into the idle suitable second bars of the first cross bar 11 and the second cross bar 12 respectively. In the through holes 112, 122, the H-type fracture reduction operating rod of the present invention can be formed, where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com