Lightning protection device for ultrasonic welding machine

An ultrasonic welding and lightning protection device technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of burnout of anti-surge components, damage of ultrasonic welding machine components, and easy breakdown and burning of lightning protection devices. Bad and other problems, to weaken the surge current, protect the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

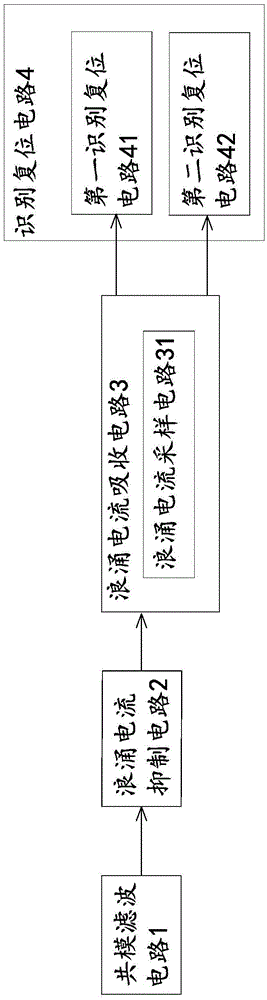

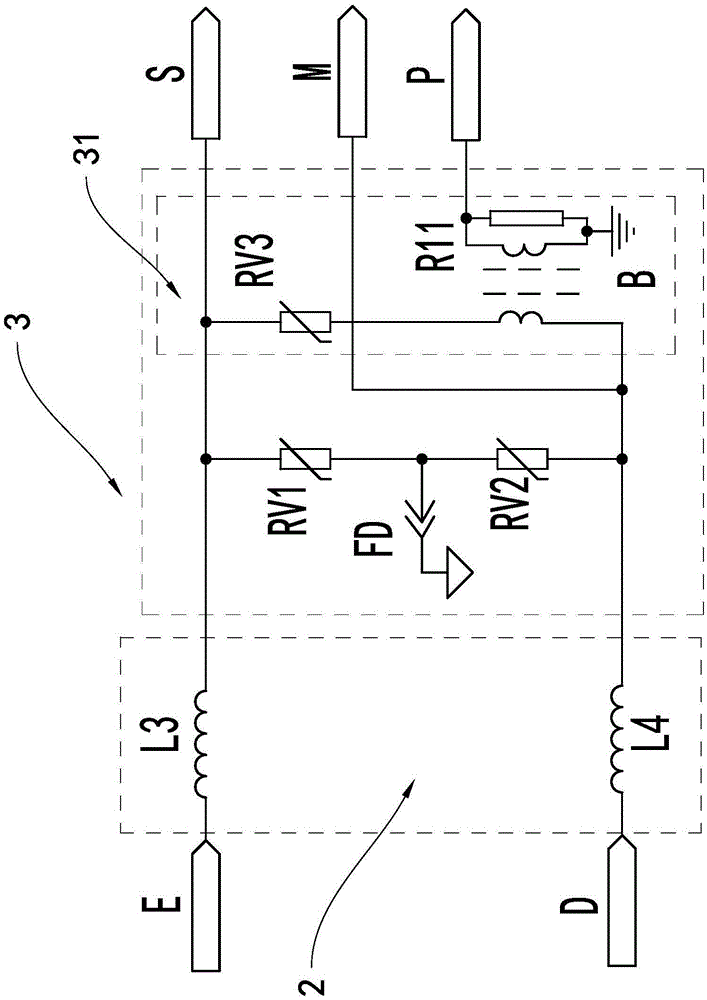

[0025] see figure 1 , The power consumption system of this embodiment includes a common mode filter circuit 1, a surge current suppression circuit 2, a surge current absorption circuit 3 and an identification reset circuit 4, and the surge current absorption circuit 3 supplies power to the ultrasonic welding machine. Wherein, the surge current absorbing circuit 3 includes a surge current sampling circuit 31 , and the identification reset circuit 4 includes a first identification reset circuit 41 and a second identification reset circuit 42 .

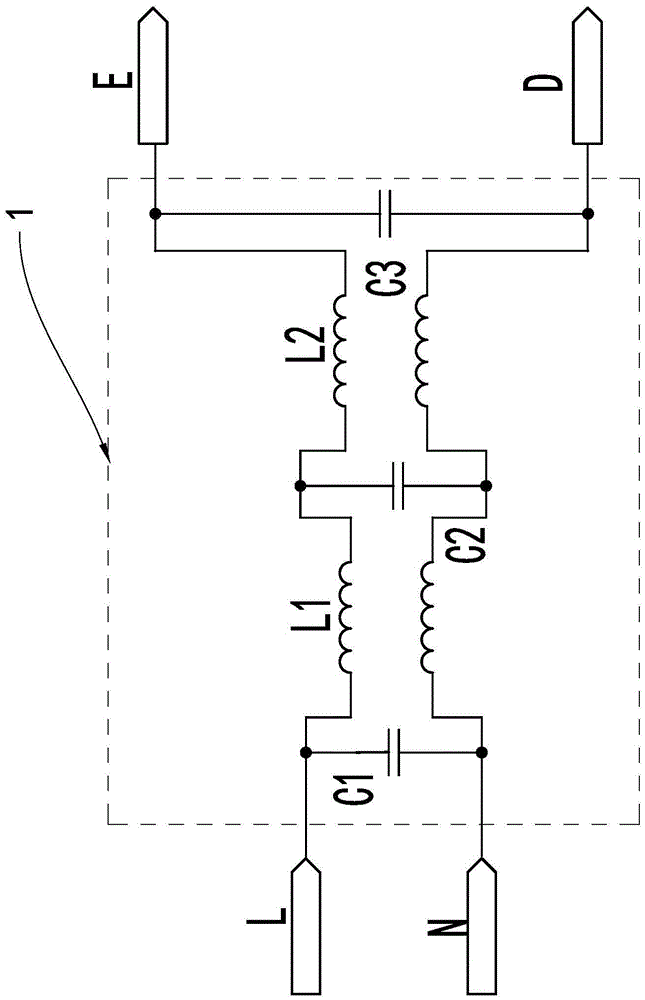

[0026] The common-mode filter circuit 1 receives the current of the grid, and the current of the grid flows in from the L port or the N port; the surge current suppression circuit 2 receives the common-mode filter signal output by the common-mode filter circuit 1, and the surge current suppression circuit 2 pairs common The analog filter signal is subjected to surge suppression processing; the surge current absorption circuit 3 receives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com