Aircraft engine fuel pump bearing flow and associated system and method

An aero-engine and engine technology, which is applied in the direction of engine lubrication, turbine/propulsion fuel delivery system, charging system, etc., and can solve problems such as pressure increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

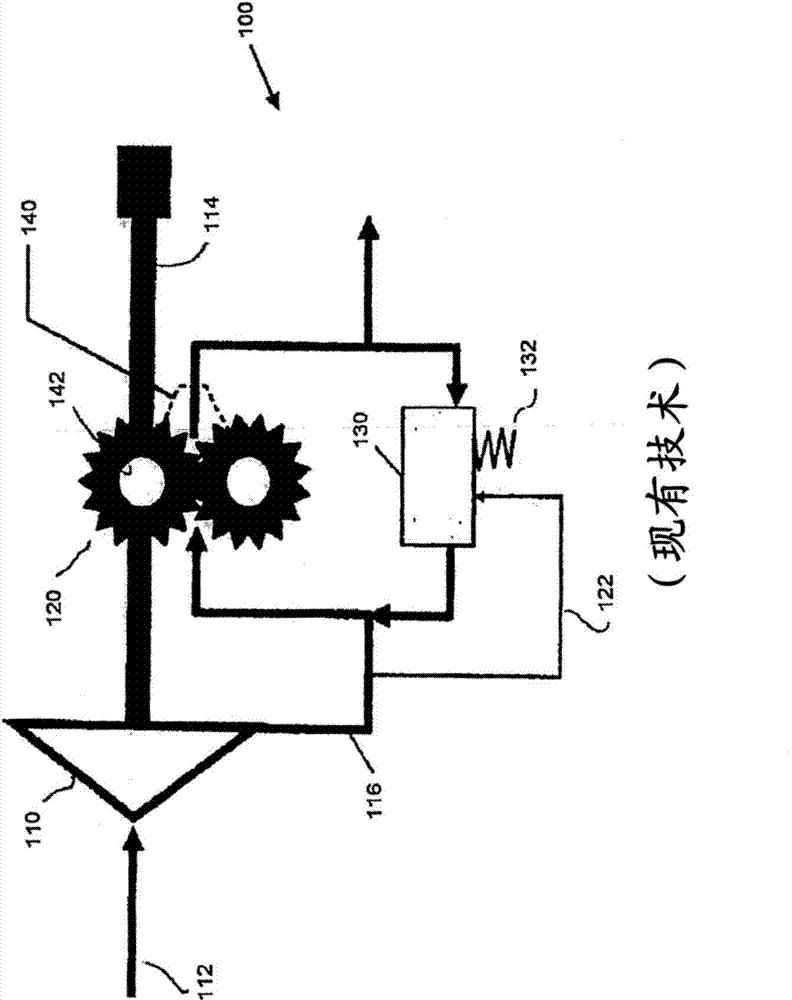

[0027] figure 1 A typical pump that provides a constant supply of bearing lubrication flow to the radial bearings of a pump, such as a high pressure stage pump. More particularly, system 100 includes a first or booster stage pump 110, shown schematically as a centrifugal pump. Fluid enters at 112 to booster stage pump 110 , which is rotated by drive shaft 114 . The output 116 from the boost stage pump 110 is provided to a second or high pressure stage pump 120 downstream of the boost stage. High pressure pump 120 is also driven by shaft 114 . Reference signal 122 is also provided from outlet 116 of booster stage pump 110 to pressure relief valve 130 . Pressure relief valve 130 is biased toward the closed position by means of a biasing member, such as spring 132 . Pressure relief valve 130 receives flow from high pressure pump 120 and if the pressure of the output flow from the high pressure pump provides a force that exceeds the combined signal 122 from booster stage pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com