Motor-driven type automatic knife rest revolution device

An automatic knife, motor-driven technology, applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low work efficiency and high labor intensity of personnel, and achieve high work efficiency, mechanized automation, and worker labor. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

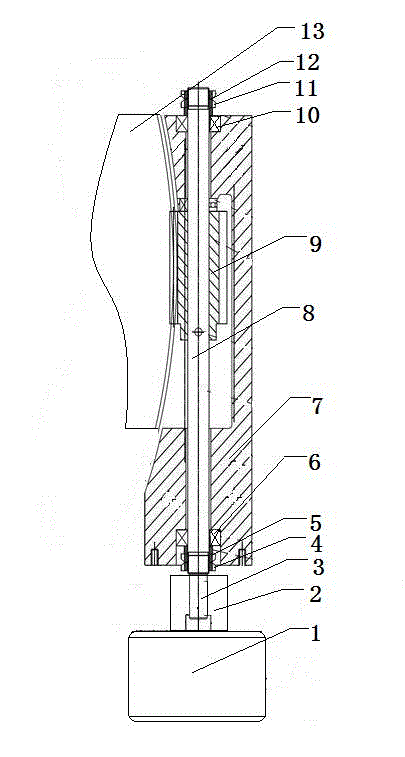

[0011] This embodiment provides a motor-driven automatic tool post rotary device, which is characterized in that: the motor-driven automatic tool post rotary device includes a driving machine (1), a reducer (2), an output shaft (3), The first nut (4), the first adjusting pad (5), the first bearing group (6), the sleeve (7), the lead screw (8), the worm (9), the second bearing group (10), the second Nut (11), second adjusting pad (12), knife rest (13);

[0012] Among them: the driving machine (1) is connected with the reducer (2), the reducer (2) is set on the output shaft (3) of the driving machine (1), the output shaft (3) is connected with the lead screw (8), the lead screw (8 ) The lower end is fixedly installed with the first bearing group (6) through the first nut (4), the first adjusting pad (5) is arranged between the first nut (4) and the first bearing group (6), and the lead screw (8 ) is installed with a worm (9) in the middle, and a shaft sleeve (7) is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com