Fully-automatic continuous processing equipment for solid wood components

A kind of processing equipment and fully automatic technology, applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of poor adaptability, inability to process multiple wood strips, single function, etc., and achieve large interval space, strong adaptability and Retrofitability and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

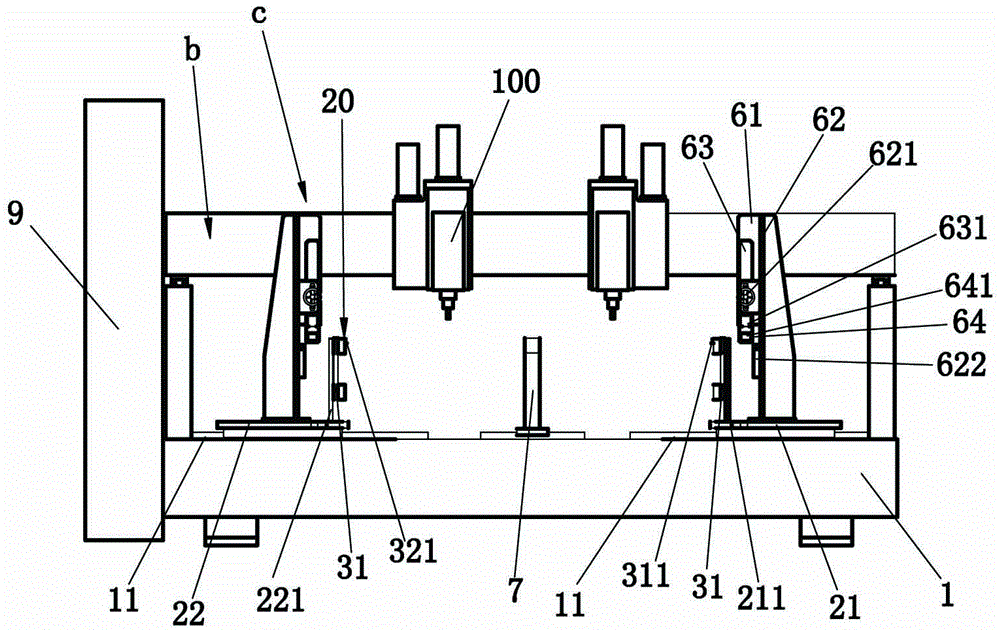

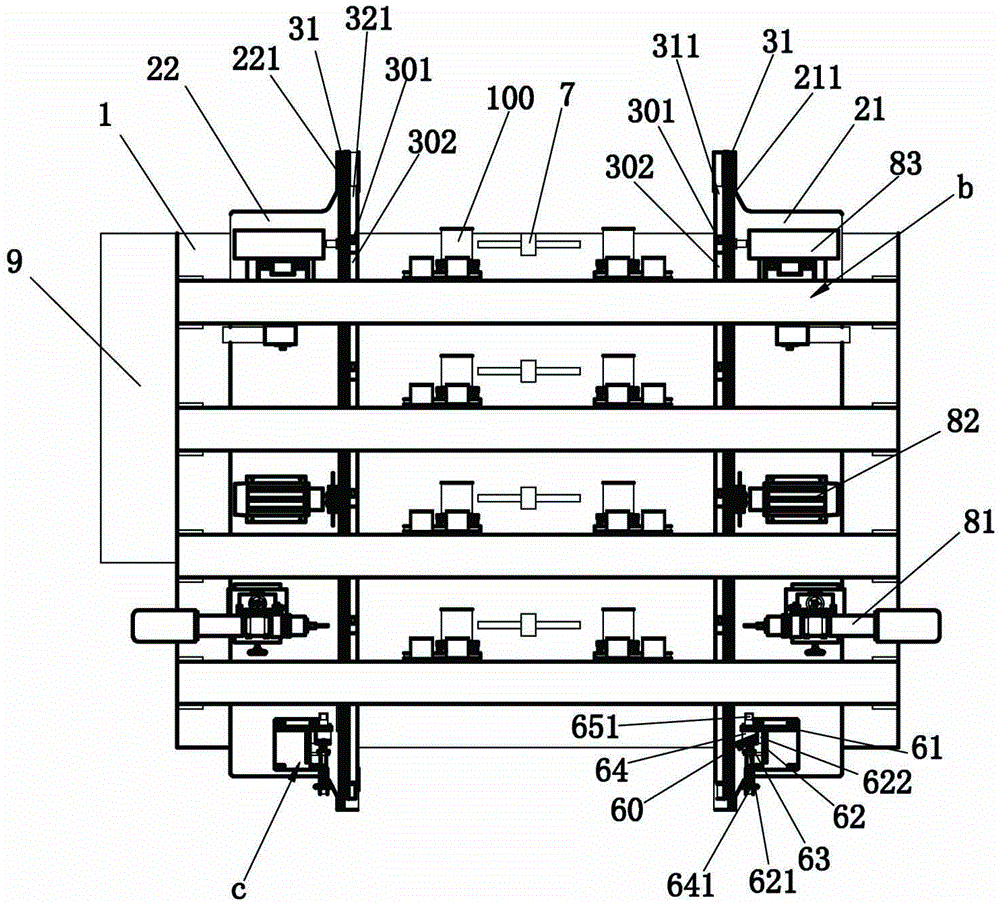

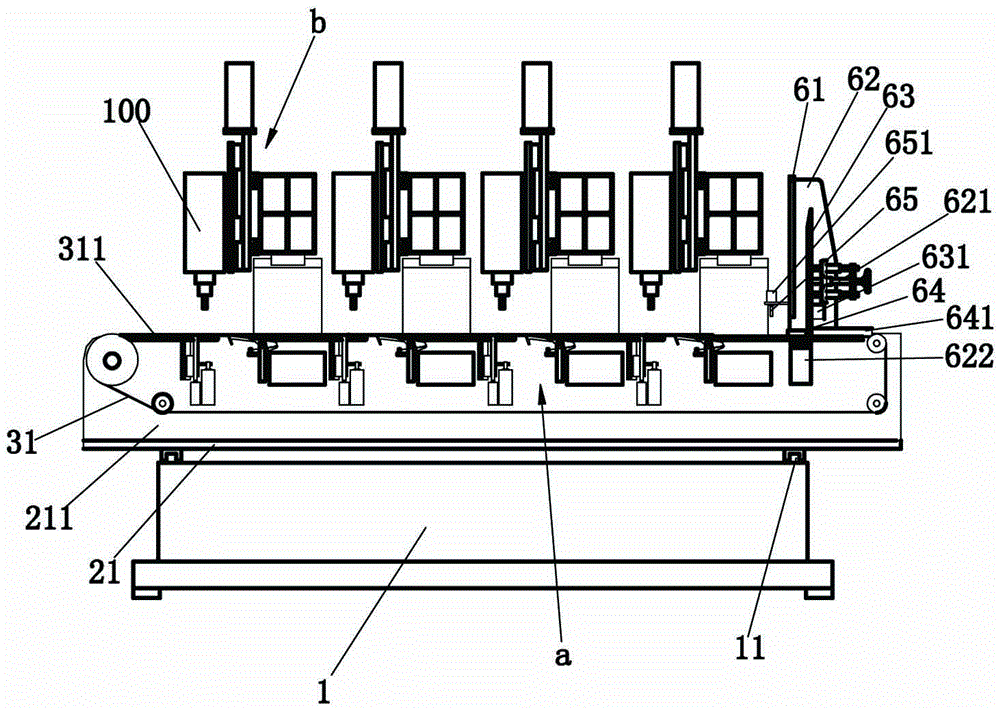

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0031] refer to figure 1 , figure 2 and image 3 , a kind of fully automatic continuous processing equipment for solid wood parts, comprising a base 1 and a cabinet 9, the base 1 is provided with a work surface 20, and the work surface 20 is provided with a vertical direction along the length of the wood strip on the work surface 20 Conveying mechanism for horizontal conveying. The worktable surface 20 is provided with a plurality of stations along the transmission direction of the above-mentioned conveying mechanism, and each station is provided with a processing tool 100 for processing the upper surface of at least one pair of wooden strips above the worktable surface 20, and each station is provided with A flip positioning mechanism a that can flip the wooden strips by 90° and fix them.

[0032] refer to figure 1 , figure 2 and image 3 , As a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com