Flexible barrier with additional connection structure

A technology for connecting structures and flexible nets, applied in infrastructure engineering, protective equipment, excavation, etc., to optimize load distribution, reduce replacement or maintenance requirements, and improve cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

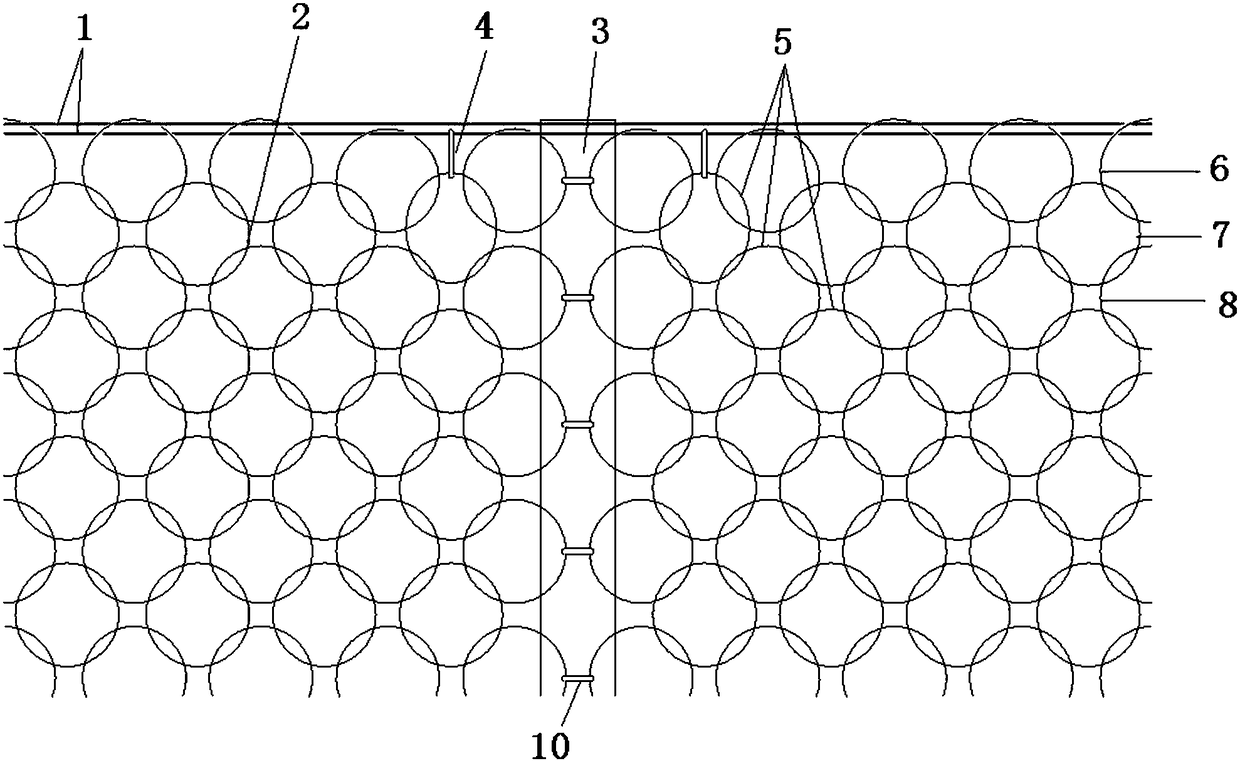

[0030] Such as figure 1 As shown, the top of the end support column and the middle support column 3 are horizontally deployed with two sets of top support ropes 1 , and two adjacent flexible metal meshes 2 are connected by connecting pieces 10 near the middle support column 3 . At the support node where the top support rope 1 intersects with the middle support column 3, the two mesh holes next to the middle support column 3 in the second row of mesh holes 7 of the metal flexible net 2 are added through the connecting ring 4 and a set of top support rope 1. At the same time, the four edge meshes 6 nested with the two secondary row meshes 7 are also connected to the group of top support ropes 1, and other edge meshes 6 of the metal flexible mesh 2 are connected with another Set the top support rope to 1 connection.

Embodiment 2

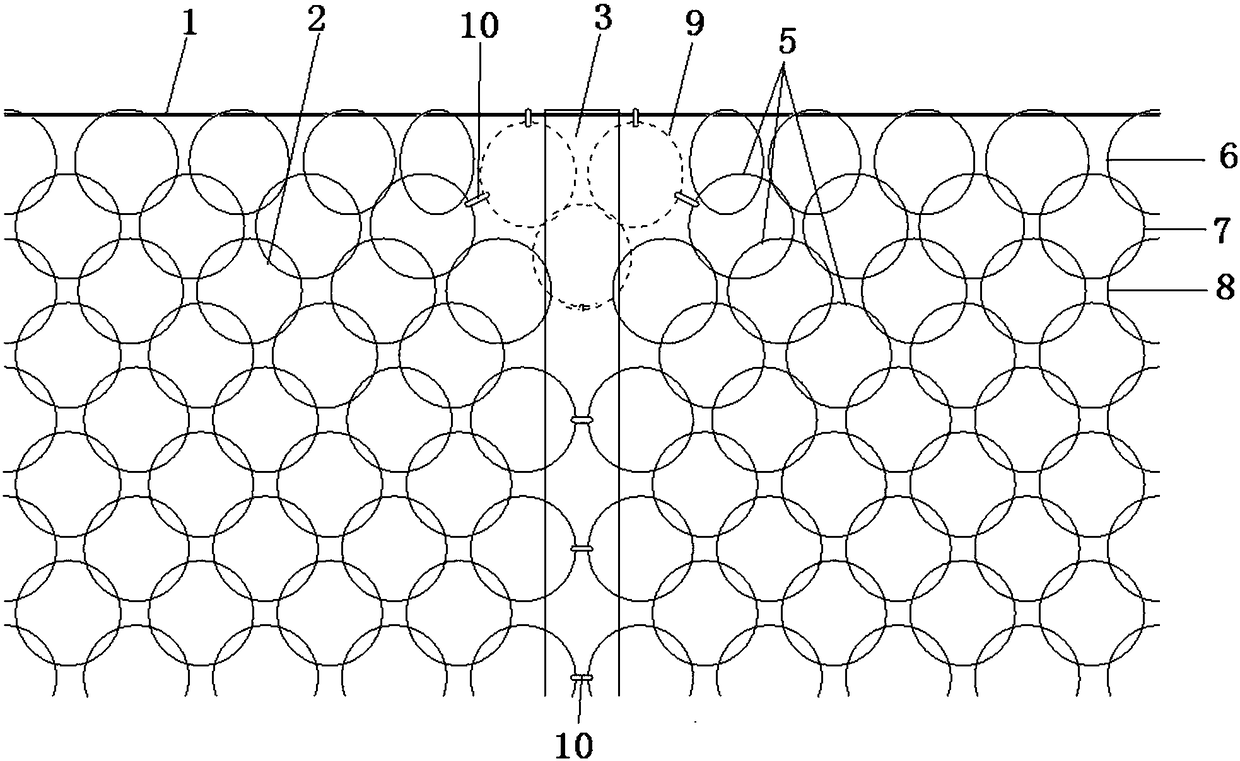

[0032] Such as figure 2 As shown, there is only one group of top support ropes 1 horizontally deployed on the top of the end support column and the middle support column 3, and the edge meshes 6 of the metal flexible net 2 are all connected with the top support rope 1. Three additional meshes 9 are added at the support node where the top support rope 1 intersects with the middle support column 3, wherein two additional meshes 9 are respectively connected to the top support rope 1 and the second row of mesh holes 7 through the connector 10. Two connections adjacent to the middle support column 3. Another additional mesh 9 is socketed with the above two additional meshes 9, and is socketed with two of the three rows of meshes 8 of the metal flexible mesh 2 that are closest to the middle support column 3.

Embodiment 3

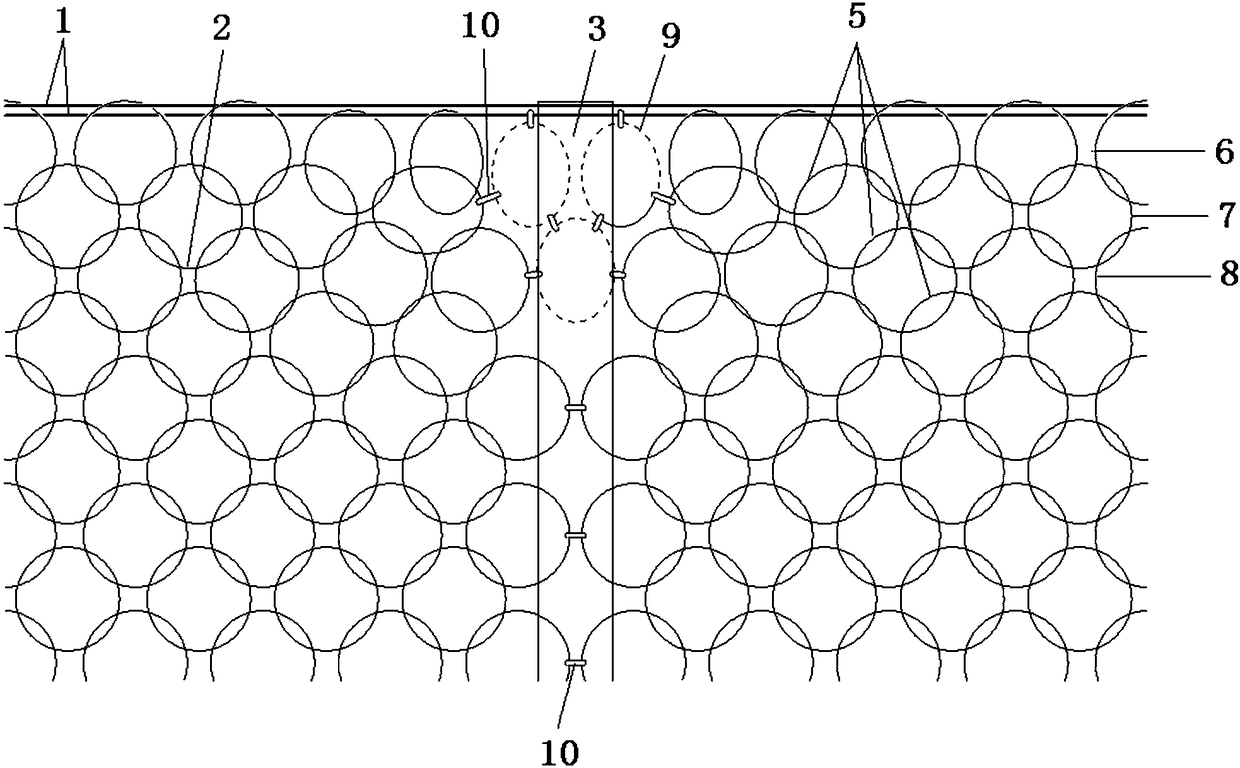

[0034] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that two sets of top support ropes 1 are horizontally deployed on the top of the end support column and the middle support column 3, wherein only one set of top support rope 1 is connected with two additional meshes 9. Connecting pieces 10 are used to connect the additional meshes 9 and between the additional meshes 9 and the second row of meshes 7 and the third row of meshes 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com