Flood pipe belt group of superstandard flood in embankment

A super-standard, pipe belt technology, which is applied in water conservancy projects, water conservancy engineering equipment, buildings, etc., can solve the problems of small area value, few use opportunities, and large losses, so as to prevent dikes from breaching, facilitate use and management, and reduce engineering costs. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

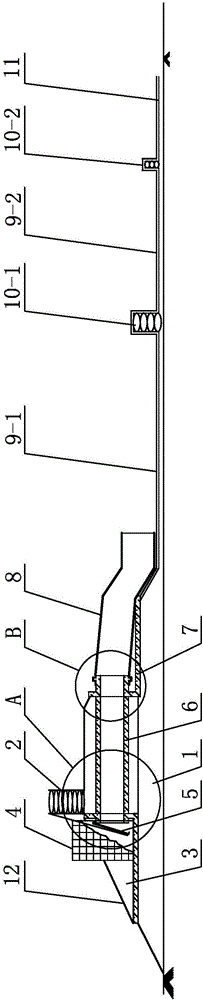

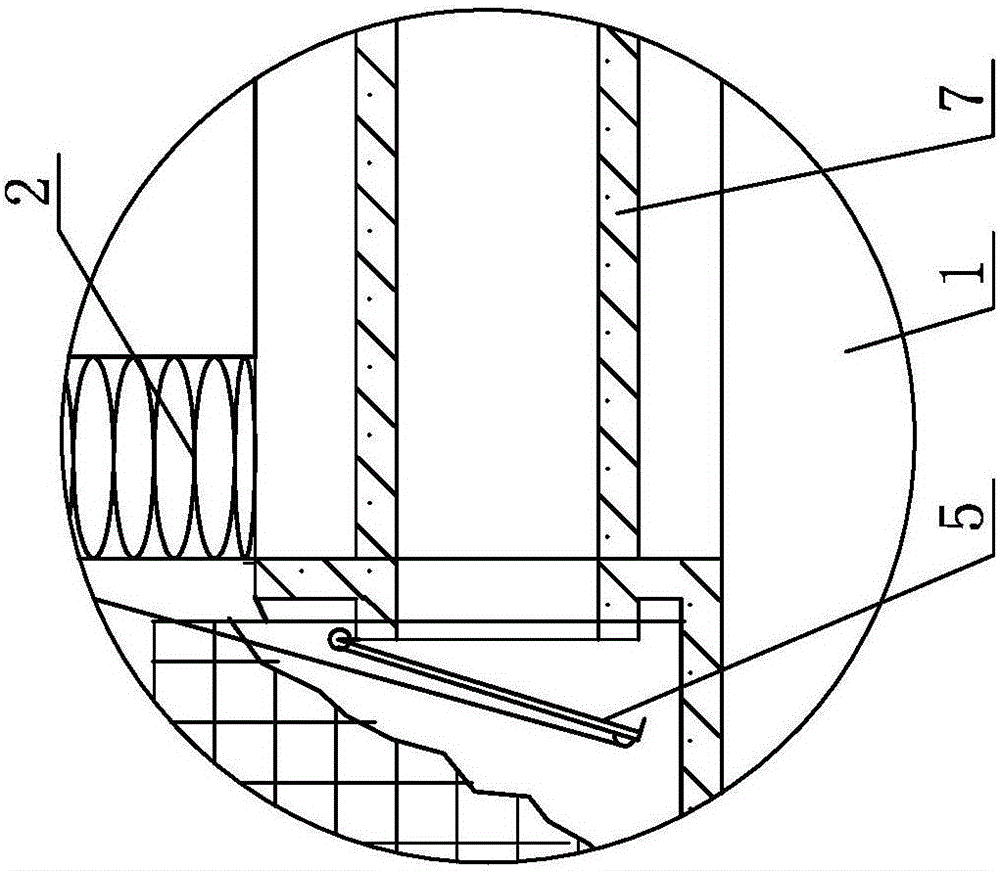

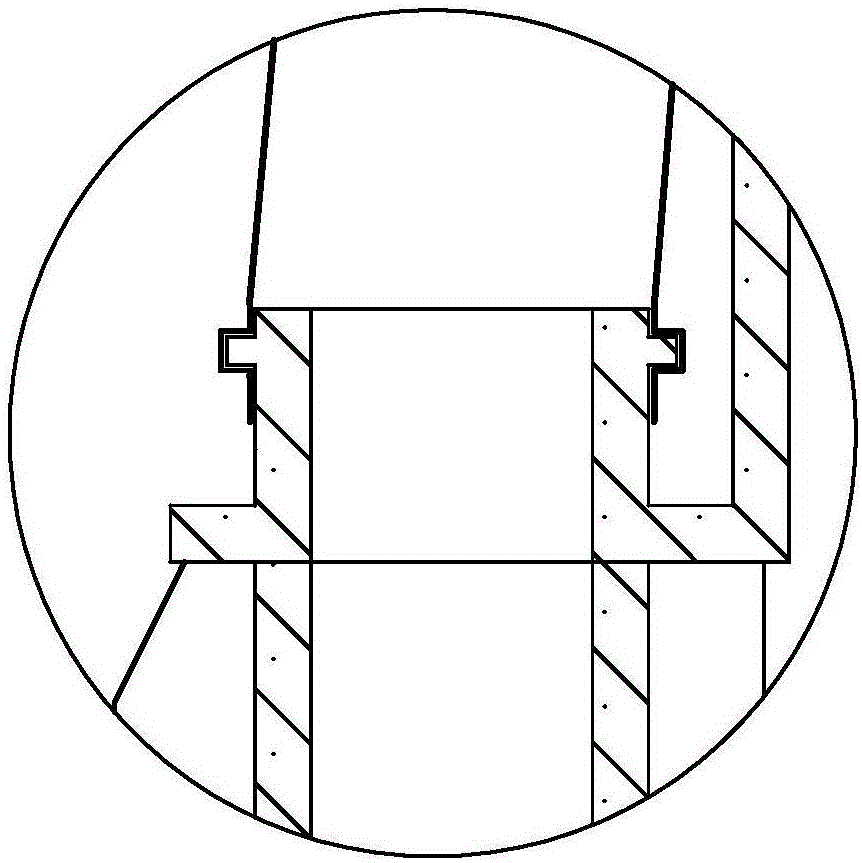

[0024] Specific implementation mode one: as Figure 1 ~ Figure 4 As shown, the flood diversion pipe belt group of the superstandard flood of the embankment of the present embodiment, the said flood diversion pipe belt group includes several flood diversion pipe belts, and the said several flood diversion pipe belts all include imported hafnium U-shaped grooves 3, cage-type trash retention Grid 4, HDPE clapper door 5, flood diversion pipe body 6, hafnium U-shaped groove at the outlet 7, water delivery belt of rigid skeleton artificial synthetic material 8, stilling tank apron of two-stage geosynthetic material, two-stage sandbag stilling sill and Color strip sandbag anti-shock section 11;

[0025] The stilling basin apron of the two-stage geosynthetic material is respectively the stilling basin apron 9-1 of the first-level geosynthetic material and the stilling basin apron 9-2 of the second-stage geosynthetic material, and the two-stage sandbag The stilling sills are the first...

specific Embodiment approach 2

[0026] Specific implementation mode two: as figure 1 and Figure 4 As shown, the flood diversion pipe belt group of the embankment superstandard flood described in the specific embodiment one, the diameter of the inner chamber of the flood diversion pipe body 6 and the water conveyance belt 8 of rigid skeleton artificial synthetic material is calculated by the following formula: formula one

[0027] formula two

[0028] formula three

[0029] In the formula: d——is the diameter of the inner cavity of the flood diversion pipe body 6 or the rigid skeleton artificial synthetic material of the water delivery belt 8, m;

[0030] Q——is the flow rate of the flood pipe belt group at the flood point, m 3 / s;

[0031] π——is the circumference ratio;

[0032] mu c - is the discharge coefficient of the flood diversion pipe body 6 or the artificial synthetic material of the rigid skeleton 8;

[0033] n——is the number of the flood pipe body 6 of the flood pipe belt group or th...

specific Embodiment approach 3

[0041] Specific implementation mode three: as figure 1 and Figure 4 As shown, the flood diversion pipe belt group of the embankment superstandard flood described in the first or second embodiment, the distance between every two adjacent flood diversion pipe bodies 6 of the flood diversion pipe belt group is calculated by the following formula:

[0042] B=d+2L k tg(β) Formula 4

[0043] In the formula: B—— is the 6-axis distance between two adjacent flood pipe bodies in the flood pipe belt group, m;

[0044] d——is the diameter of the inner cavity of the flood pipe body 6 or the rigid framework artificial synthetic material of the water delivery belt 8, m;

[0045] L k ——The length of the stilling basin apron 9-1 for the first-grade geosynthetic material, m;

[0046] β——is the diffusion angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com