A 60° double-row automatic piling device

A piling device and automatic technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of low piling efficiency, high piling quality, low safety factor, etc., to improve piling efficiency, small size, and improve work ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

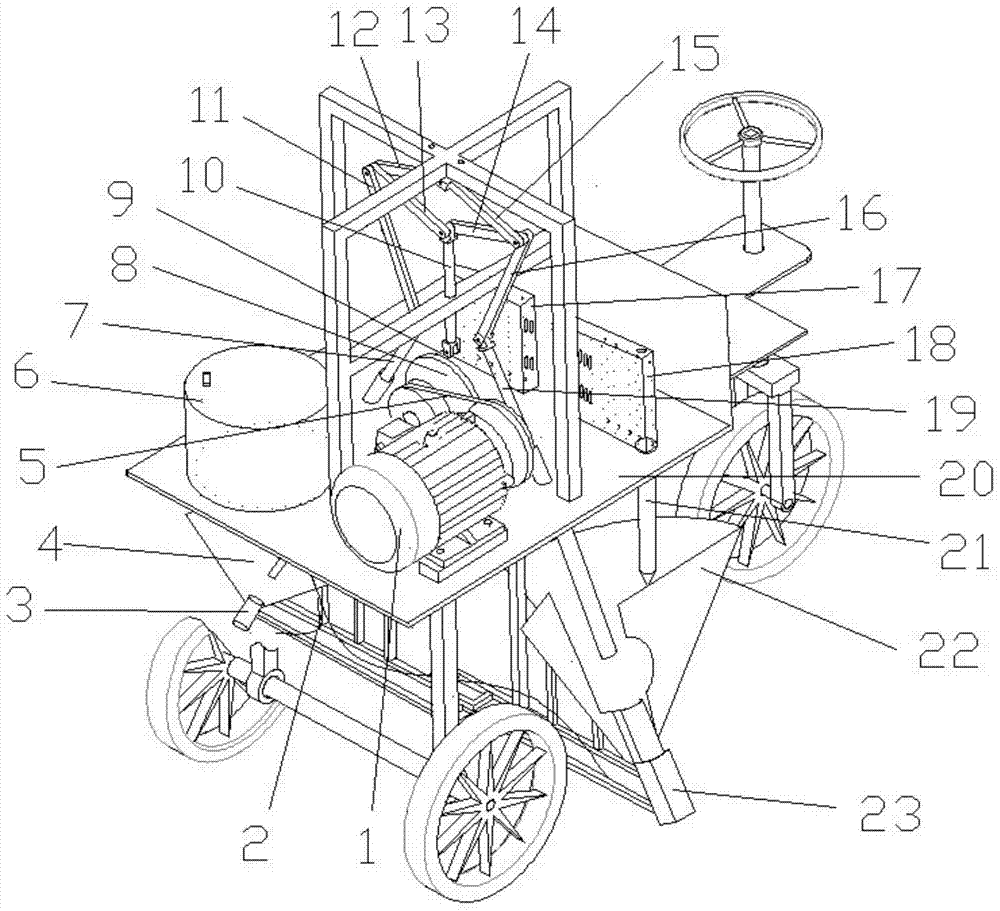

[0023] Such as figure 1 As shown, a 60° double-row automatic piling device of the present invention includes a motor 1, a water delivery pipe 2, a No. I 60° positioning pipe 3, a No. I hopper 4, a triangle belt 5, a water storage bucket 6, and a No. I impact rod 7 , eccentric wheel 8, first link 9, vertical bar 10, second link 11, rocker A 12, rocker B 13, rocker C 14, rocker D 15, third link 16, No. Ⅰ Stocker 17, No. II stocker 18, No. II impact bar 19, frame 20, stake 21, No. II hopper 22, No. II 60° positioning pipe 23.

[0024] Move the piling device to the position where piling needs to be done by adjusting the steering wheel, step on the brake device, fix the piling device, turn on the switch of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com