An efficient and compact double-row automatic piling device

A piling device, compact technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of not being able to tilt the piling, low safety factor, high safety factor, etc., to achieve improved working capacity, light weight, and improved safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

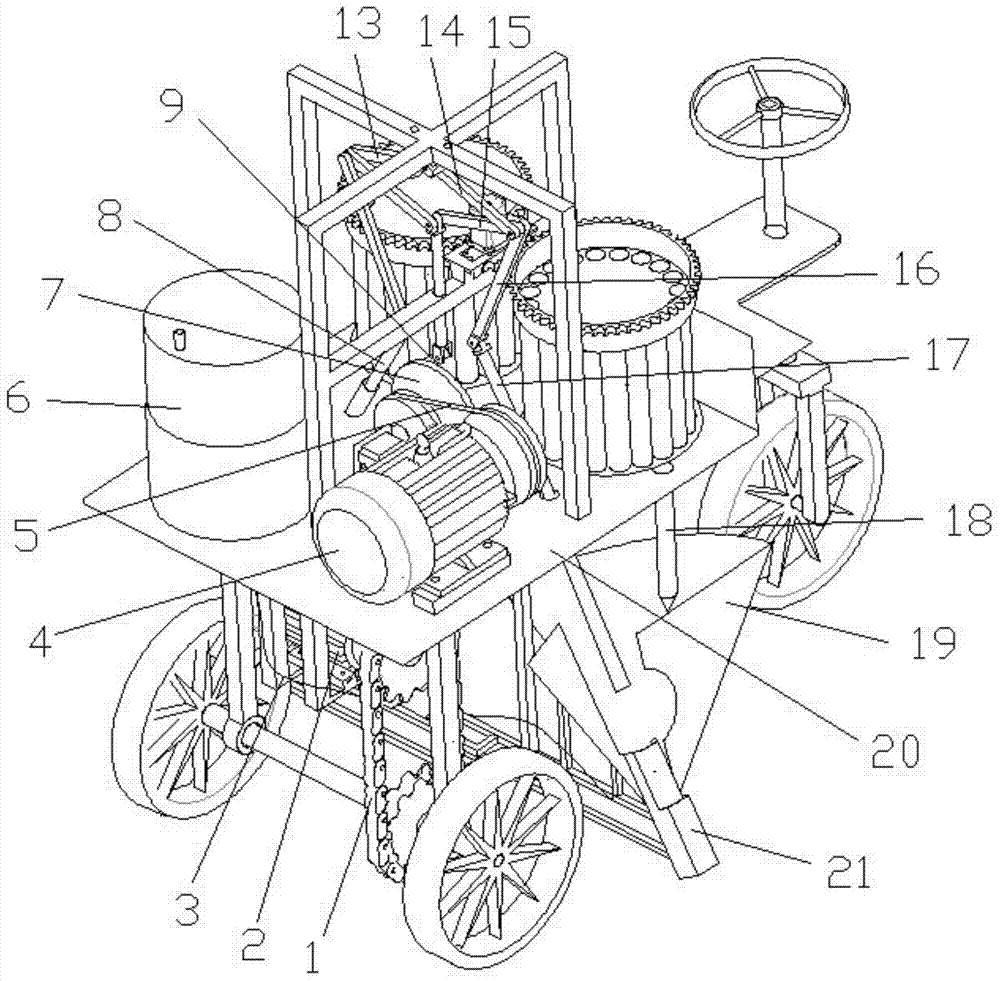

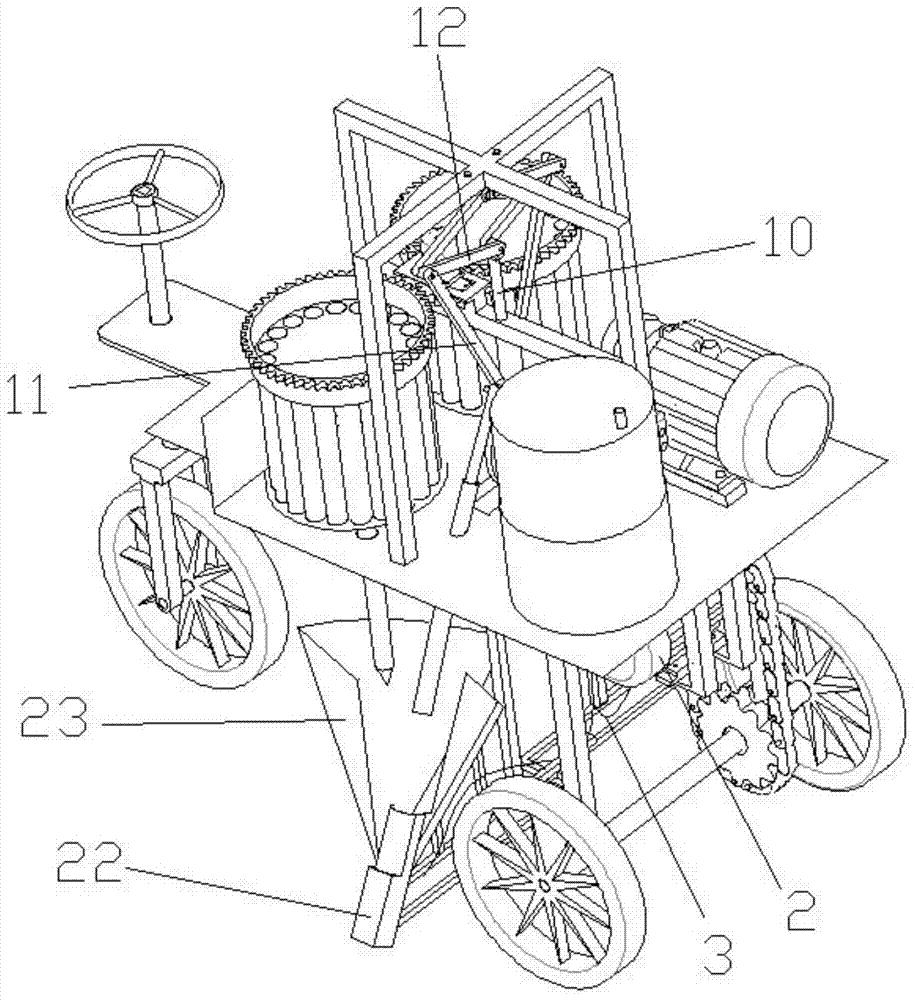

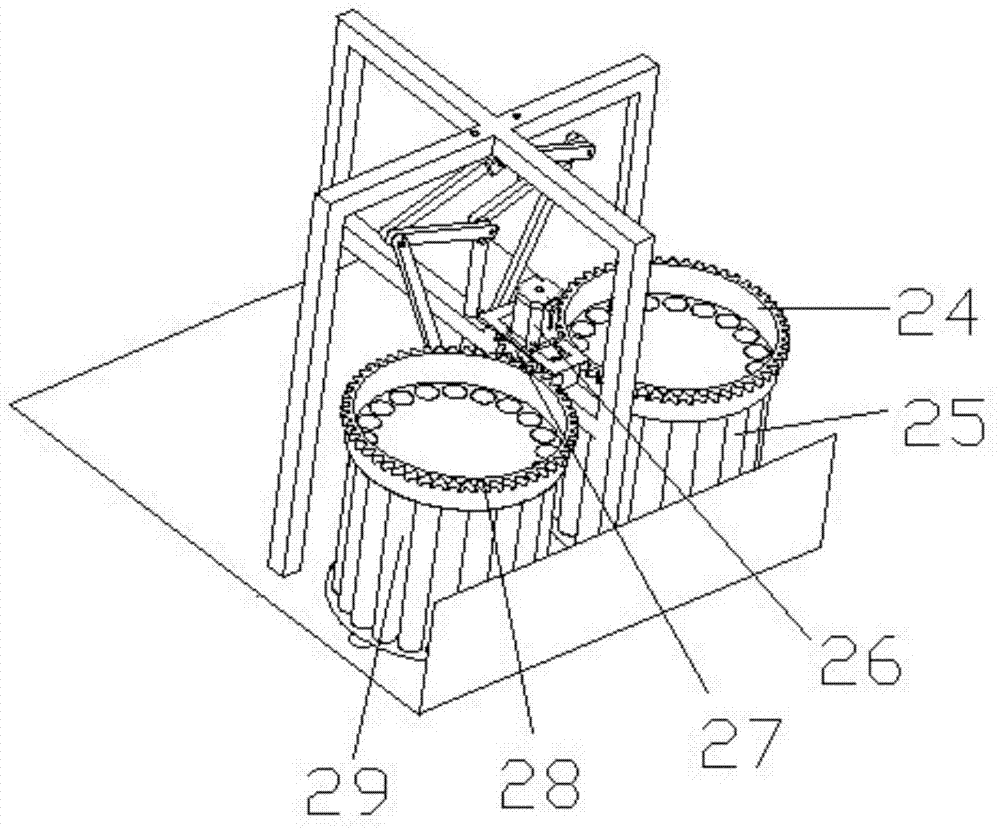

[0028] Such as figure 1 As shown, a high-efficiency and compact double-row automatic piling device of the present invention includes a chain 1, a No. Rod 8, connecting rod Ⅰ 9, vertical rod 10, connecting rod Ⅱ 11, rocker A 12, rocker B 13, rocker C 14, rocker D 15, connecting rod Ⅲ 16, impact rod Ⅱ 17, wood pile 18, No. Ⅱ transition chute 19, rack 20, No. Ⅱ 60° positioning tube 21, No. 1 60° positioning tube 22, No. 1 transition chute 23, No. 1 barrel gear 24, No. Ⅰ Barrel 25, stepper motor 26, gear 27 for stepper motor, gear 28 for No. II barrel, No. II barrel 29.

[0029] Turn on No. II motor 2, drive the piling device forward through the chain and the sprocket, and move the piling device to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com