Connection structure of prefabricated steel concrete members and its construction method

A technology of prefabricated assembly and connection structure, applied in the direction of building structure, construction, etc., can solve the problems of high construction intensity, difficult construction quality control, and high technical requirements, to simplify the construction process, reduce the influence of difficult-to-control factors, and ensure construction. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

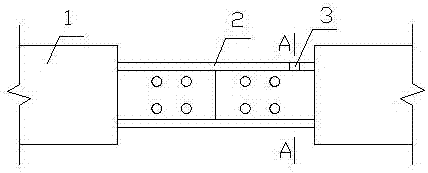

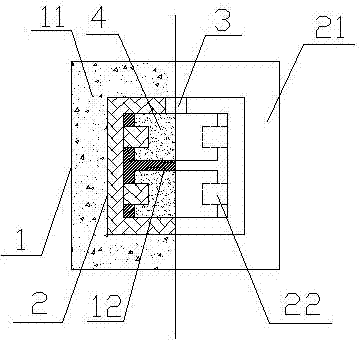

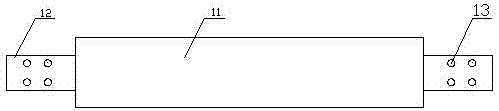

[0027] A connection structure of prefabricated steel concrete components, that is, a connection structure in which two prefabricated steel concrete components 1 are connected through a connector 2 . The prefabricated steel concrete member 1 is prefabricated by concrete 11 and steel 12, and is in the shape of a square column. The steel 12 adopts I-beam; Cut bolt hole 13. The connector 2 is a pin bolt grouting sleeve type, the main body is two separate U-shaped fasteners 21, and the U-shaped fasteners 21 are welded with shear bolts corresponding to the shear bolt holes 13 reserved at the end of the section steel 22, and reserve a semicircular grouting hole 23. When the two U-shaped fasteners 21 are fastened together, the two semicircular grouting holes 23 form a complete circular grouting hole 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com