Deepwater pipe in pipe buckle arrestor based on deformed element with Y-type section

A technology of deformation element and pipe in pipe, which is applied in the direction of pipeline damage/abrasion prevention, pipeline protection, pipeline laying and maintenance. Effect of buckling and buckling propagation, saving production overhead costs, increasing thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

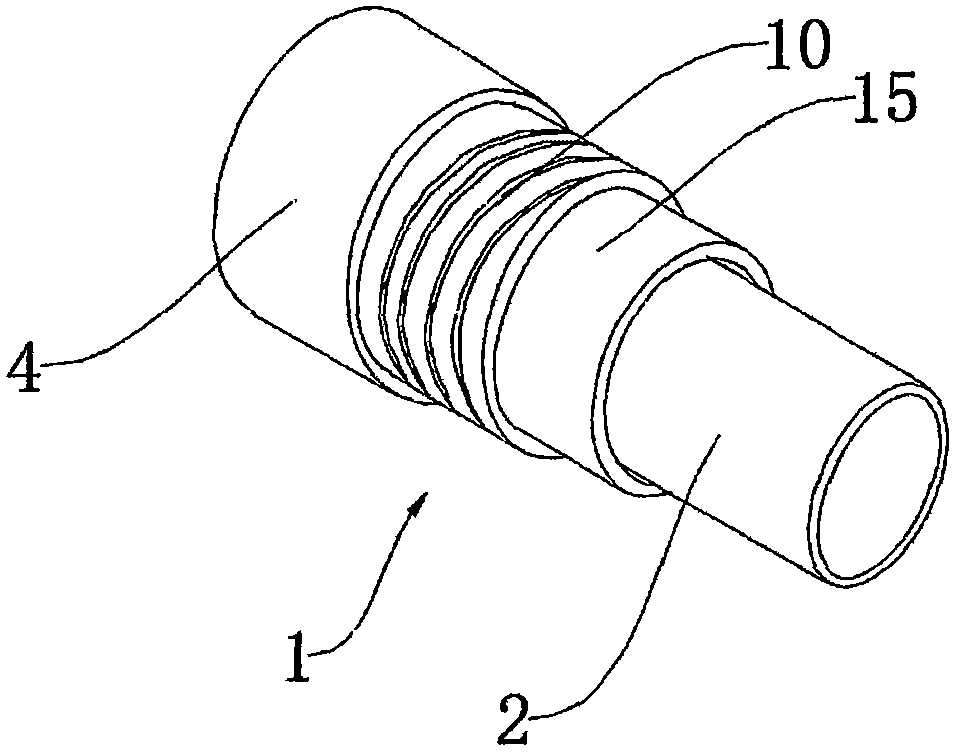

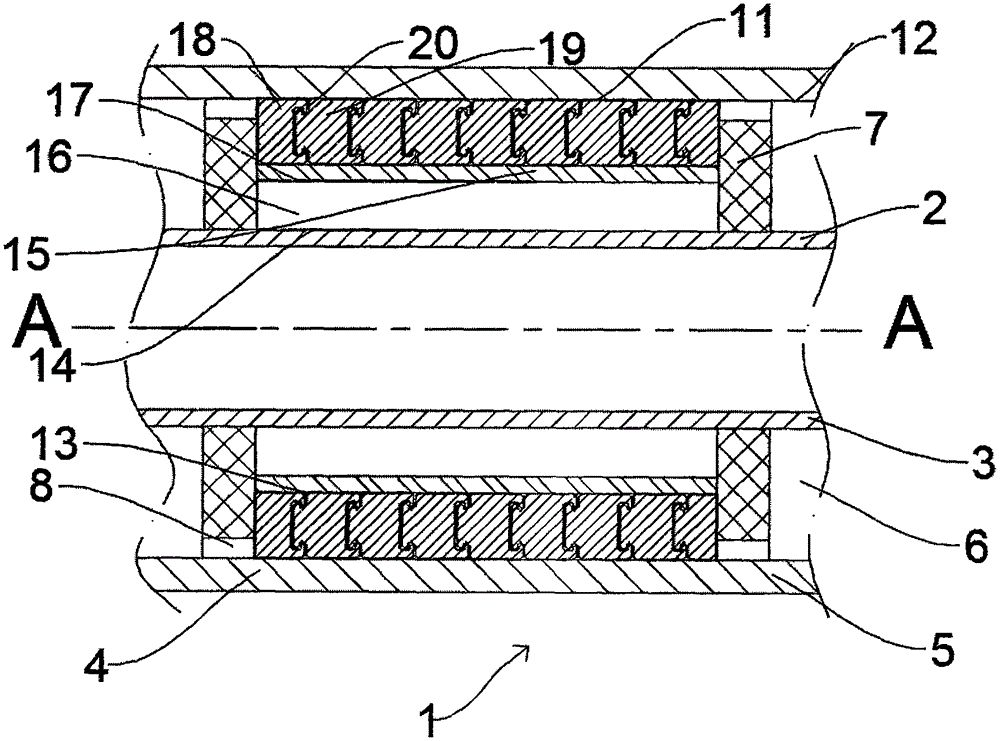

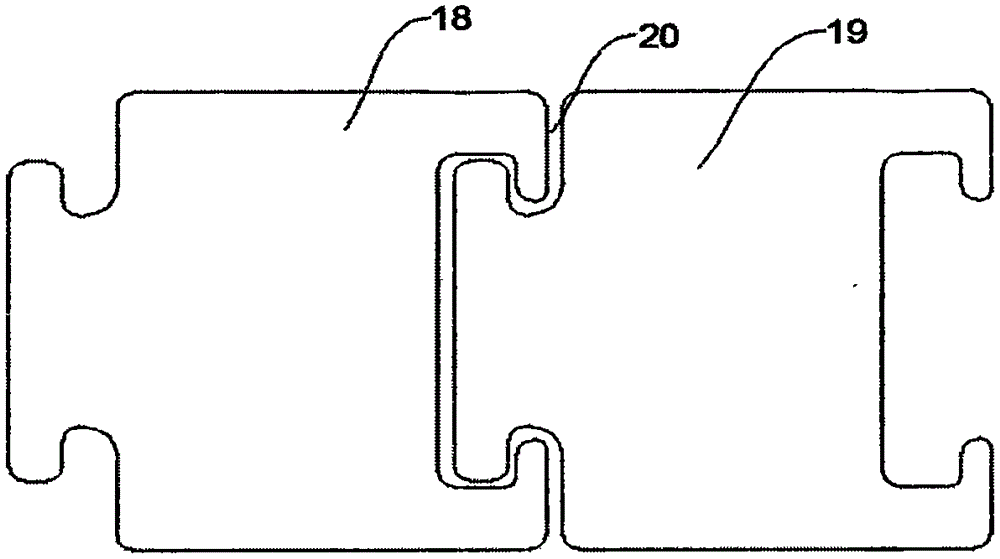

[0026] Such as figure 1 As shown, the tube-in-tube 1 is composed of an inner tube 2 and an outer tube 4 . The Y-shaped cross-section deformation element 10 is helically wound in the annular space between the inner and outer pipes at an angle close to 90 degrees to the length direction of the pipe, and its outer surface has at least two points of contact with the inner wall of the outer pipe, and its inner surface is separated from the outer surface of the inner pipe. not in contact.

[0027] Such as figure 2 As shown, the central axis of the tube-in-tube 1 is AA. In the annular space 6 of the inner tube 2 and the outer tube 4, the nuclear type buckle arrester described in this patent is installed. The nuclear type buckle arrester consists of a spacer ring 7, one or more deformation elements 10 ( figure 1 , whose cross-section is figure 2 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com