LED lens emitting light from plane and design method of LED lens

A LED lens and plane technology, applied in the field of systems or instruments, and optical components, can solve problems such as difficult cleaning and low light output efficiency of LED lenses, and achieve the effects of easy cleaning, maintaining optical performance, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

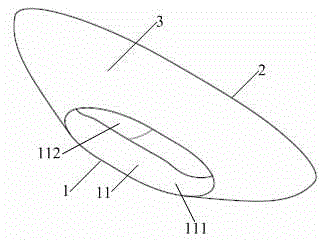

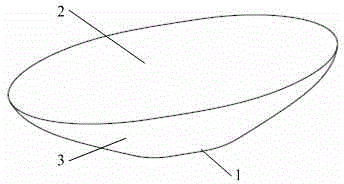

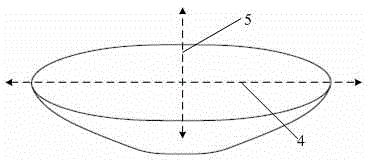

[0027] See attached Figures 1 to 3 , a planar light-emitting LED lens, comprising a top, a side and a bottom 1, characterized in that: the top is a light-emitting surface 2, the side is surrounded by a reflective cup surface 3, the bottom 1 is provided with an inner concave cavity 11, and the light-emitting surface 2 is The inner concave cavity 11 includes a top surface and a draft surface 111 , and the top surface is a free-form surface 112 .

[0028] Further, the reflective cup surface 3 is arranged around the side, so that the light that does not enter the lens from the free-form surface 112 passes through the reflective cup 3 and then emerges from the plane light-emitting surface 2 on the top, reducing the total reflection of the outgoing surface and improving the light-emitting efficiency of the lens.

[0029] Further, the lens includes two light transmission paths, the first transmission path is: a part of the light is refracted into the lens through the free-form surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com