Device and method for detecting air flow distribution in cigarette smoking process

An air flow and detection device technology, which is applied in the detection of air flow distribution during cigarette smoking, and in the field of detection devices for air flow distribution, to achieve the effects of simple structure, guaranteed sealing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

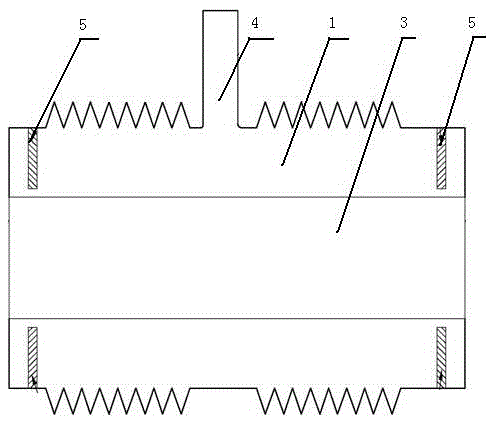

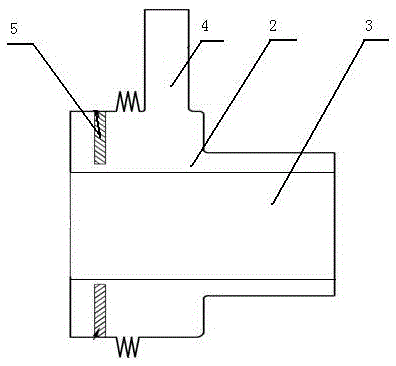

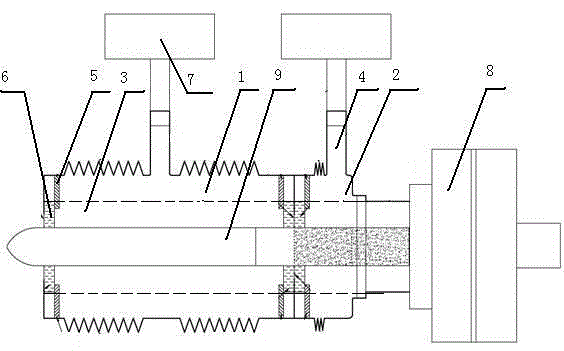

Image

Examples

Embodiment 1

[0049] Take a certain brand of cigarettes, marked as sample 1#, use a single-channel smoking machine to smoke cigarettes according to the conditions specified in the ISO standard according to the above method of use, and detect the air inflow of each part of the cigarette when the sample is drawn for the first puff. The filter section of this sample is 24mm, the cigarette branch section is 60mm, and the circumference is 24.5mm.

[0050] According to the operation steps of the method of the present invention, according to the circumference of the cigarette, a thick cigarette sealing ring is selected at the end of the through hole, and the cigarette passes through the through hole and is clamped in the detection device of the present invention, and the two sections of the corrugated part of the side wall of the cigarette paper section are pulled Stretch to 18.5mm, and compress to 3mm at a section of the corrugation on the side wall of the filter cavity. Through testing, the air ...

Embodiment 2

[0052] Take a certain brand of cigarettes, marked as sample 2#, use a single-channel smoking machine to smoke cigarettes according to the conditions specified in the ISO standard according to the above-mentioned method of use, and detect the air inflow of each part of the cigarette when the sample is smoked for the first puff. The filter section of this sample is 30mm, the cigarette branch section is 77mm, and the circumference is 17mm.

[0053] According to the operation steps of the method of the present invention, according to the circumference of the cigarette, a thin cigarette sealing ring is selected at the end of the through hole. Stretch to 19mm, and stretch to 9mm at a section of corrugation on the side wall of the filter cavity. Through testing, the air flow rate of the filter section of the sample is 13.09mL, and the air flow rate of the cigarette paper section is 2.94mL. According to the principle of flow balance, the air flow rate of the burning cone end is 18.97m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com