Integrated groundwater hydraulic gradient measuring device

A hydraulic gradient and measuring instrument technology, applied in the field of measuring instruments, can solve the problems of cumbersome operation, inability to obtain the magnitude and direction of groundwater seepage flow velocity, time consumption, etc., and achieve the effect of automatically obtaining data, improving measurement accuracy, and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

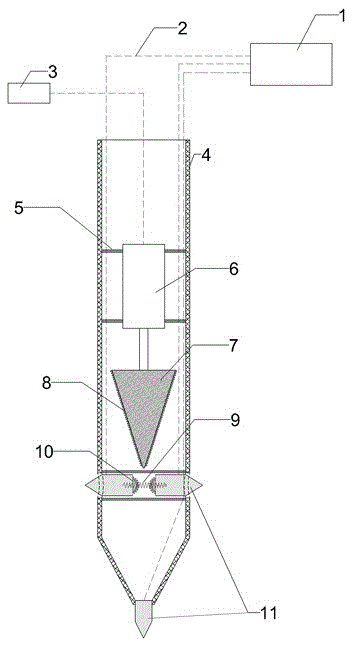

[0017] An integrated groundwater hydraulic gradient measuring instrument, comprising: a hollow tube, a gap on both sides of the hollow tube, a pressure sensor 11 placed at the bottom of the hollow tube and the gap, recording the head value measured by the pressure sensor 11 The inspection instrument 1 is controlled, and the pressure sensor 11 at the control gap extends or retracts the telescopic assembly of the gap; the pressure sensor 11 and the inspection instrument 1 are connected by a wire 2. In order to fix the electric push rod 6 and ensure that the pressure sensor at the notch can only telescopically move, the hollow tube is provided with a fixing bracket 5 for fixing the electric push rod 6; as a preference, the hollow tube is a steel pipe.

[0018] In order to realize the extension gap and retraction gap of the pressure sensor 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com