Secondary-etching double-sided circuit board and processing technology thereof

A double-sided circuit board and secondary etching technology, which is applied to printed circuit components, chemical/electrolytic methods to remove conductive materials, etc., can solve the problems of uncontrolled product quality, long cycle time, and high cost investment. , to achieve the effect of simplifying the production process and operation difficulty, reducing the cost of PCB production, and reducing the investment of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

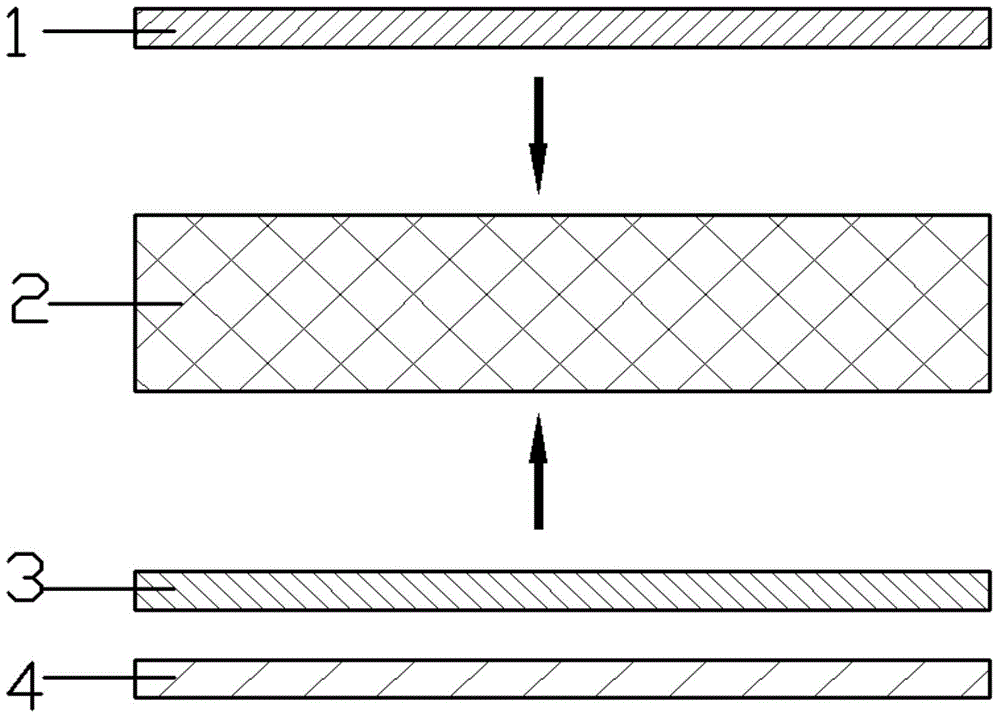

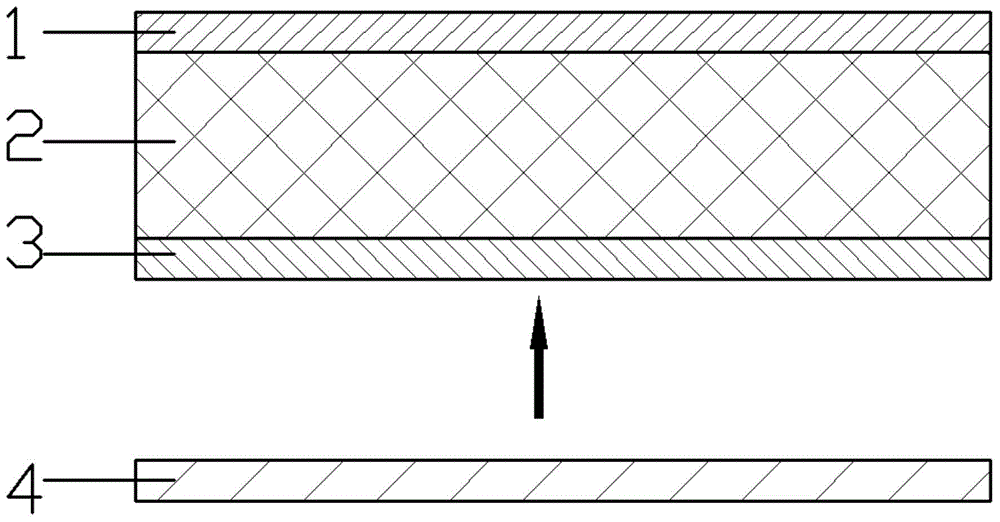

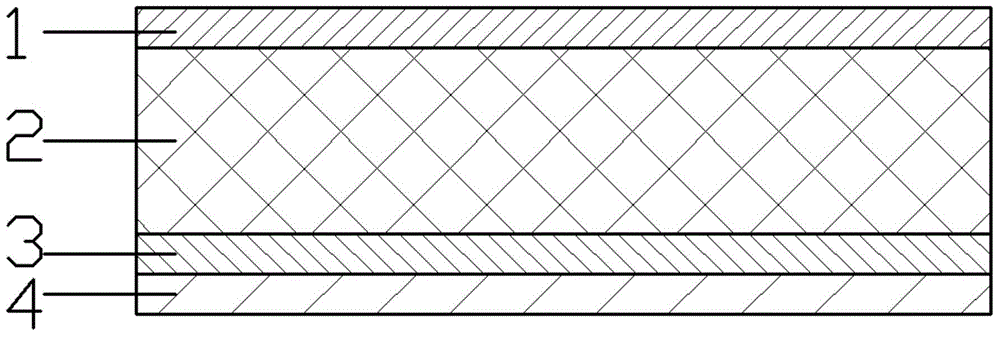

[0028] refer to image 3 As shown, a double-sided circuit board is etched twice, comprising: GTL line layer 1, insulating PP layer 2 and GBL step surface line layer, and the GBL step surface line layer is composed of GBL inner line layer 3 and GBL outer line layer 4 Composition, the GTL line layer 1 and the GBL inner line layer 3 are connected to the insulating PP layer 2 at the same time, the GBL outer line layer 4 covers the GBL inner line layer 3, the GBL outer line layer 4 and the GBL inner line layer 3 has similar appearance and shape, but the size of GBL outer circuit layer 4 is 0.05mm larger than the size of GBL inner circuit layer 3,

[0029] The processing technology of the second etching double-sided circuit board: includes the sub-flow of the first circuit manufacturing process and the second sub-flow of the circuit manufacturing process.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com